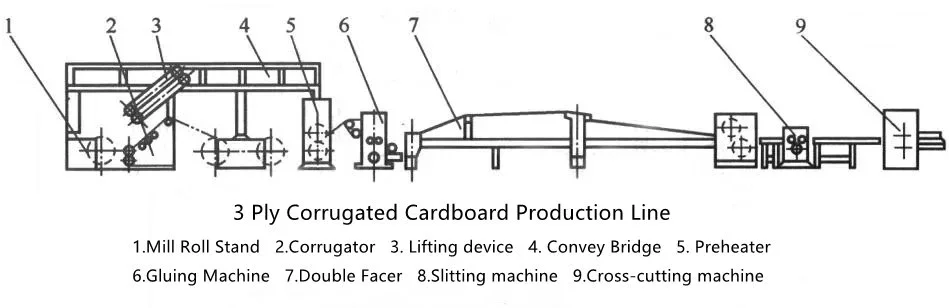

The 3 ply corrugated cardboard production line, also known as the 3-layer corrugated production line, is specialized automated equipment designed for manufacturing 3-ply corrugated boards (consisting of face paper, corrugated medium, and inner paper). Integrating processes such as paper feeding, heating, corrugation forming, gluing, laminating, drying, edge trimming, and paper cutting, this production line enables continuous and efficient production of high-quality 3-ply corrugated boards.

Based on customers’ production scales and market demands, the 3-ply production line is categorized into three types: ordinary type, medium-speed type, and high-speed type. It can be flexibly configured with units of different specifications to meet diverse requirements for production capacity, board quality, and automation level.

Technical Parameters Of 3 Ply corrugated cardboard production line

– Working Width:

1400 mm, 1600 mm, 1800 mm, 2000 mm, 2200 mm, 2500 mm (optional)

– Design Speed:

– Ordinary type: 60–100 m/min

– Medium-speed type: 120–150 m/min

– High-speed type: 180–250 m/min

– Flute Type:

– Flute A (thickness approx. 4.5–5.0mm, excellent cushioning performance, suitable for pressure-resistant packaging)

– Flute B (thickness approx. 2.5–3.0mm, good flatness, suitable for high-quality printing)

– Flute C (thickness approx. 3.5–4.0mm, balancing strength and flatness)

– Flute E (thickness approx. 1.5mm, suitable for small-sized packaging and colored carton printing)

– Supports single-flute or multi-flute switching to meet diverse market needs

– Base Paper Specifications:

– Face paper & inner paper: 100–250 g/m²

– Corrugated medium: 80–180 g/m²

– Air Supply Pressure: ≥ 0.5 MPa

– Steam Supply Pressure: 0.8–1.3 MPa

– Power Consumption: Approximately 200–350 kW (varies by configuration)

– Floor Space: Approximately 45–80 meters in length (varies by machine type)

Main configuration of 3 ply cardboard production line:

Model | Name | Qty | Remarks |

ZJ-B | 3 | Expansion clip paper head, disc brake, electric drive lift, left and right translation, to medium. | |

Paper cart | 6 | The guide rail length is 5,000 mm, and the medium plate is welded. | |

SF-280 | 1 | Corrugated main roller ∅ 280 mm, alloy material plating treatment, high-efficiency and energy-saving gearbox rotation, using maintenance-free cylinder pressure, 215 rubber roller. | |

RG-1-600 | Pre-heater machine | 2 | Roller ∅ 600 mm, electric adjustment package Angle. The package Angle can adjust the heating area of the paper within the 360 range. |

GM-20 | 1 | The diameter of the adhesive roller is 240 mm. Independent frequency conversion motor drive, PLC adjustment of glue coating clearance and man-machine interface. | |

RG-1-600 | 1 | Roller ∅ 600 mm, electric adjustment package Angle. The package Angle can adjust the heating area of the paper within the 360 range. | |

ZDF | 1 | Main beam 160 mm groove steel, independent frequency conversion motor drive pull paper conveyor. | |

SM-F | 1 | Rack 300 mm national standard groove steel, chrome-plated hot plate 600 mm * 10 pieces, hot plate surface fine grinding, roller type pressure paper design structure, converter motor. | |

FY-C | Electric thin blade machine | 1 | Tungsten alloy blade, 5 knife, 8-wire type. Electric knife. |

NC-120 | 1 | Full AC frequency conversion control, energy storage braking, die-cutting knife structure, oil-immersed gear transmission, 7-inch touch screen display. | |

DM-ZJ | Right Angle stacking machine | 1 | Section 1 section platform, gear motor drive platform lift, imported high strength belt output, cross out. |

Air supply system | 1 | Customers can bring their own gas source. | |

ZJ | Glue production station system | 1 | Pipe customers shall bring themselves. The glue making device is composed of carrier tank, main tank, storage tank, glue pump and glue pump. |

Application

The 3 ply corrugated cardboard production line is a core piece of equipment for carton factories and board plants, especially suitable for small to medium-sized packaging manufacturers. It enables stable and efficient production of 3-ply corrugated board to meet diverse packaging demands.

Board plants: For bulk production and supply of 3-ply corrugated sheets to downstream carton makers or printing & packaging companies.

Carton factories: For in-house sheet production and conversion into corrugated cartons, improving cost control and delivery efficiency.

Typical downstream applications include:

Food & beverage packaging: Frozen food, snacks, beverages, agricultural products.

Consumer goods & light industry packaging: Shoes, apparel, household items, cosmetics, toys.

E-commerce & logistics packaging: Corrugated shipping boxes for online retail and parcel delivery, suitable for light to medium-weight goods.

Electronics & small appliances packaging: Lighting, small home appliances, electronic accessories, often using B-flute or E-flute for strength and better printability.

Thanks to its lightweight structure, low cost, and recyclability, 3-ply corrugated board is widely used by board plants, carton factories, and end-user packaging sectors, making this line an ideal choice for growing packaging enterprises and e-commerce packaging suppliers.