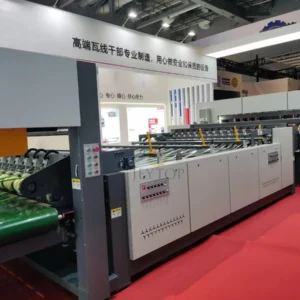

Characterics of the Double Gluer Machine:

- After quenching and tempering treatment, the surface of the gluing roll undergoes inner – hole machining, dynamic balance testing, surface finishing, and is engraved with pit – type reticulated patterns. It ensures uniform gluing and low glue consumption.

- The gluing roll is driven by a frequency – conversion motor. The frequency conversion control ensures that the linear speed of the gluing roll is synchronized with that of the double facer, and it can also operate independently.

- The glue quantity can be adjusted electrically with digital display. Automatic circulating glue supply prevents glue precipitation and maintains stable viscosity.

- It adopts a pneumatic paper – pressing structure, and the gap can be finely adjusted electrically. Both the upper and lower layers are driven by independent frequency – conversion motors.

- It measures the speed signal of the double – facer to achieve synchronous operation. It is equipped with a human – machine interface for display, making the operation simple and quick.

Technical Parameter of the double gluer machine:

| Effective width | 1400-2800mm |

| Mechanical | 150-300m/min |

| Diameter of gluing roller | 310mm |

评价

目前还没有评价