Unpacking Corrugated Boxes: A Guide to Common Box Types

Corrugated boxes are the most widely used packaging products. They are strong, reliable, and not easily deformed. They are often used for transportation and storage. Due to the different packaging items, the types of corrugated boxes used are also different. So, do you know the types of corrugated boxes?

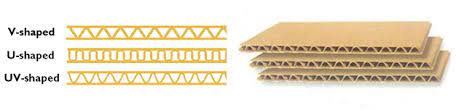

Classification according to corrugated shape

- V-shaped corrugated box: the flat surface has high pressure resistance value, which saves the amount of adhesive and corrugated base paper in use. However, the corrugated cardboard made of this kind of flute-type has poor cushioning performance, and the corrugated board is not easy to recover after being compressed or impacted;

- U-shaped corrugated carton: large glue area, firm bonding, and a certain degree of elasticity. When impacted by external force, it is not as fragile as V-shaped flute, but the plane expansion force is not as strong as V-shaped flute;

- According to the performance characteristics of V-shaped flute and U-shaped flute, UV-shaped corrugated rollers made by combining the advantages of the two have been widely used. The processed corrugated carton not only maintains the high pressure resistance of V-shaped flute, but also has the characteristics of high adhesive strength and certain elasticity of U-shaped flute.

Classification according to the corrugated shape of the cardboard

There are four main types of flute for corrugated cardboard: A flute, B flute, C flute and E flute.

- The corrugated cardboard made of A flute type has good cushioning properties and is full of elasticity.

- C flute type is inferior to A flute type, but its stiffness and impact resistance are better than A flute.

- B-type flute arrangement density is high, the surface of corrugated cardboard made is smooth, high bearing pressure, suitable for printing.

- The E flute corrugated sheet shows its rigidity because of its thinness and density.

Generally speaking, the cartons used for outer packaging mainly use A, B, and C flute Type corrugated cardboard; medium packaging uses B, E flute type corrugated cardboard; small packages mostly use E flute type corrugated cardboard.

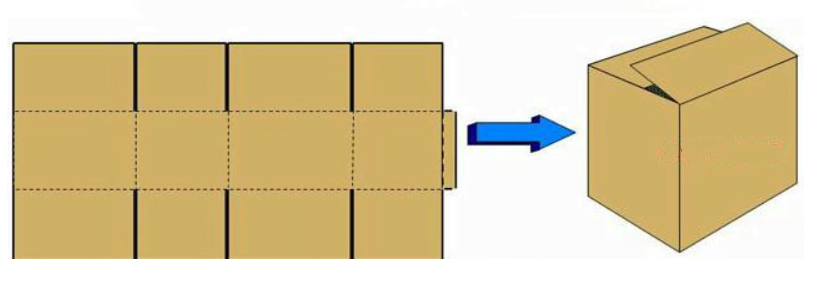

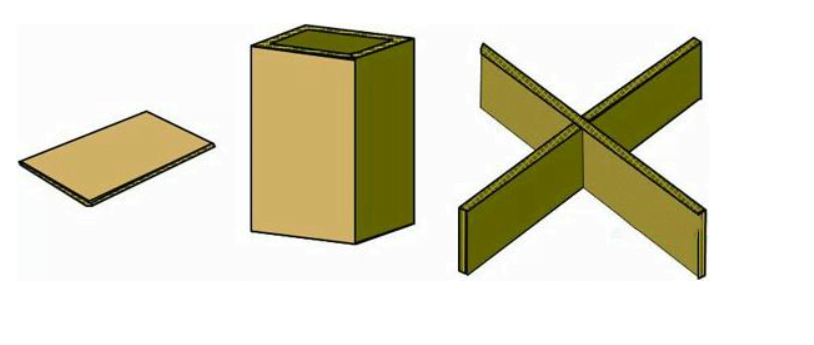

Classification according to the number of base paper layers

- Double-layer corrugated cardboard: corrugated cardboard composed of a layer of face paper and a layer of corrugated core paper

- Three-layer corrugated cardboard: corrugated cardboard composed of two layers of face paper and one layer of corrugated cardboard.

- Five-layer corrugated cardboard: a corrugated cardboard composed of three-layer face paper and two-layer corrugated core paper.

- Seven-layer corrugated cardboard: a corrugated cardboard composed of four-layer face paper and three-layer corrugated core paper.

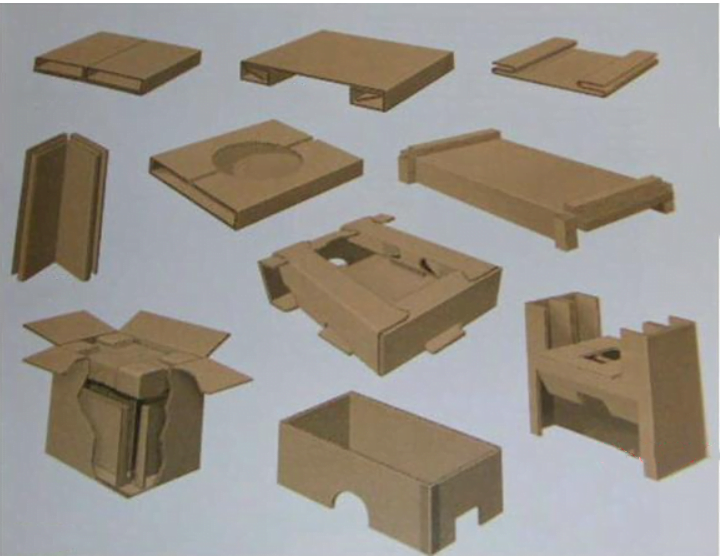

Classified by corrugated box type

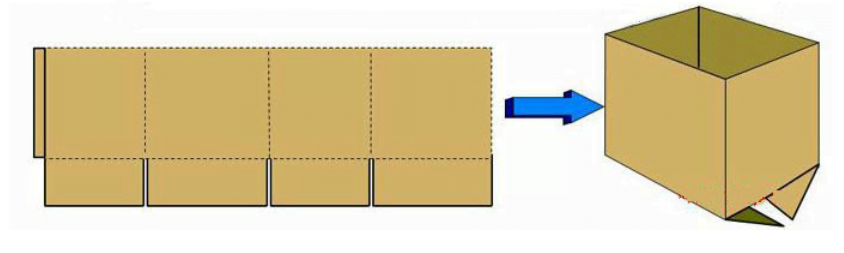

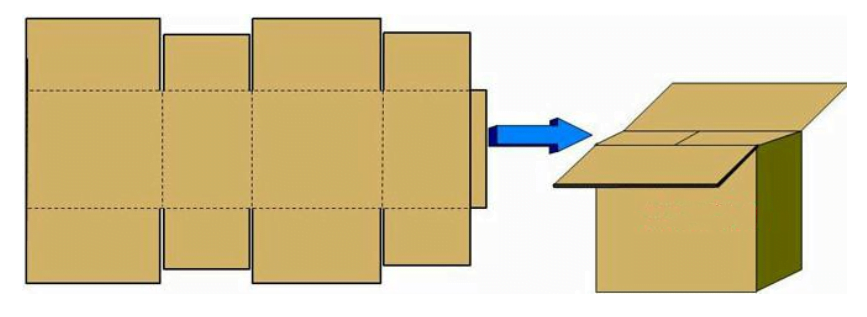

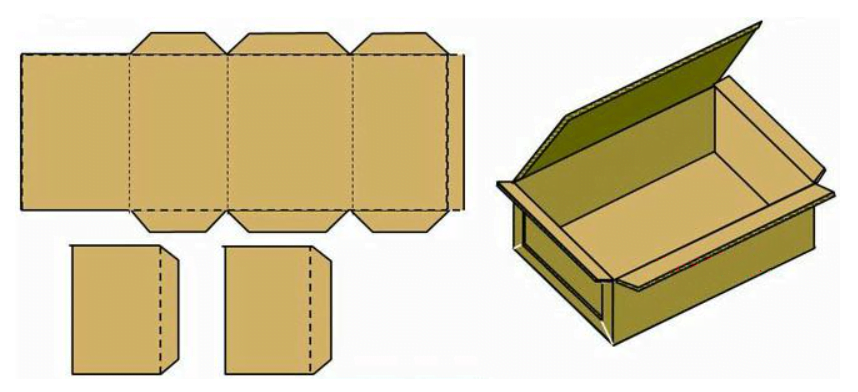

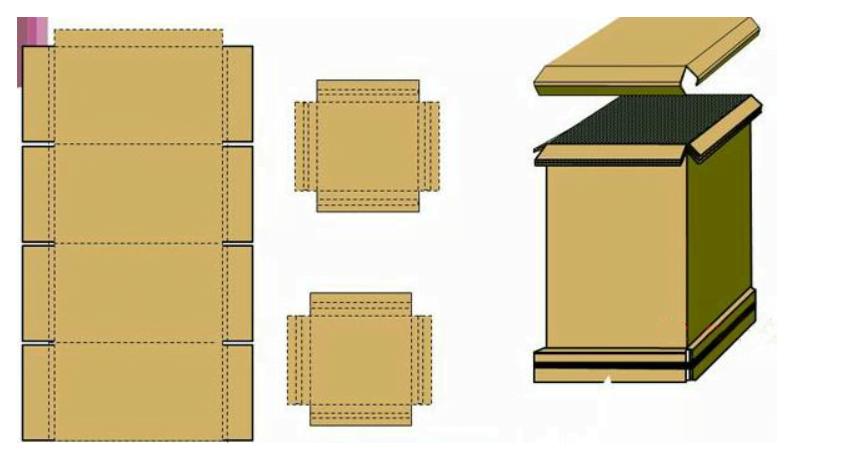

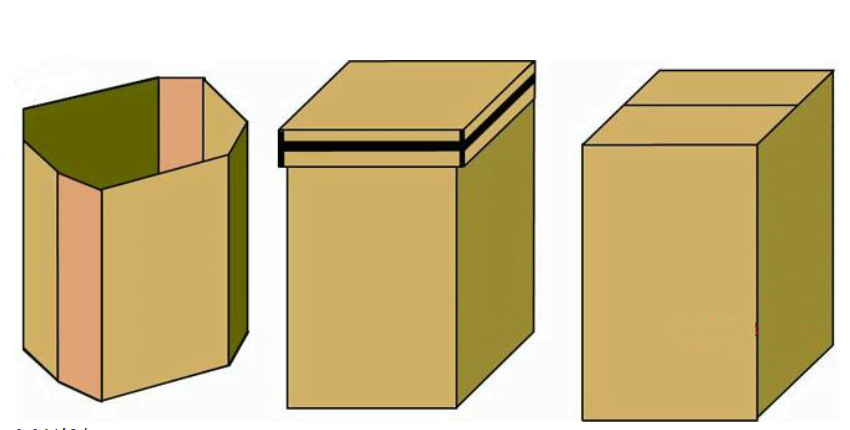

- Standard Slotted Box—RSC(Regular Slotted Container):Usually made from a single piece of cardboard slotted and formed by folding and lapping tongue staples or gluing. 80% of the cartons are RSC-type boxes, also called A-1-type boxes, ordinary boxes, flat-mouth boxes.

- Half Slotted Box—HSC: Compared with RSC, only one end has a rocker cover, also known as a half-wing box. Commonly used in the packaging of fruits, vegetables, machinery parts (automatic assembly lines) and other products.

- Overlapping Box—OSC(Overlap Slotted Container): The general design overlapping part is 2-3CM, the design is to prevent tarnishing, stealing or damage when opening the box, common in clothing, small appliances, plastic products, paper products, etc.

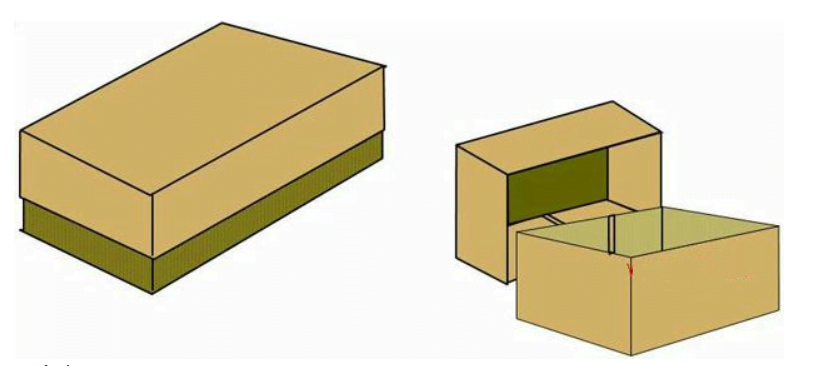

- Full Overlapping Type-FOL: Also known as full (full) wing box, the width of the flap is two parts of the standard box type, which is equal to the width of the carton. Commonly used in products with relatively small width or heavy internal contents, such as bicycles, nails, mechanical products, bowling balls and other products that require special protection during transportation and handling.

- Fully enclosed slotted box-CSSC(Center Special Slotted Container): The inner and outer flaps are of different sizes, and when folded, the inner and outer flaps are completely closed. But the outer flaps do not overlap. This box type is used for packaging bottles and canned products that require a flat bottom.

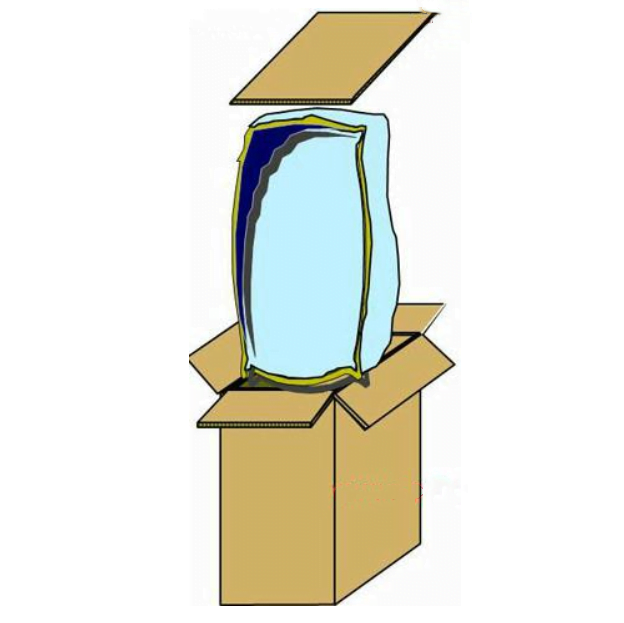

- Bag-in-Box: As the name suggests, it is to pack a plastic or composite bag in a corrugated box. This box type is used for liquid bags, dust, aseptic packaging, etc., and is mostly used for food packaging.

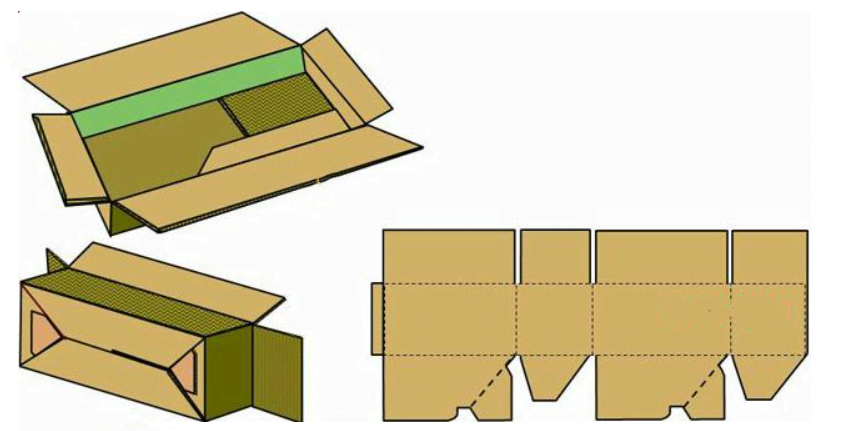

- Fully enclosed folding box-SFF: The inner and outer flaps are different in size, and the inner and outer flaps are completely closed after folding, and the outer flaps are completely overlapped, which is twice the width of the standard box. This box type is mainly designed for product packaging with flat bottom and special protection. Commonly used in machine parts and sensitive items.

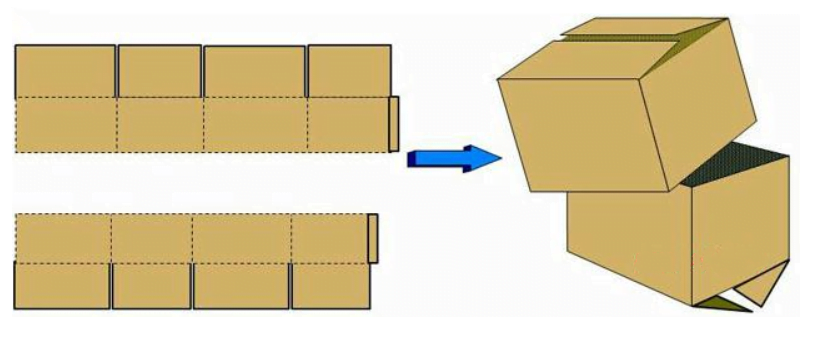

- Telescopic Box(Full fit): Another design of the combo set box. Strengthen the overall pressure resistance of the edge protection.

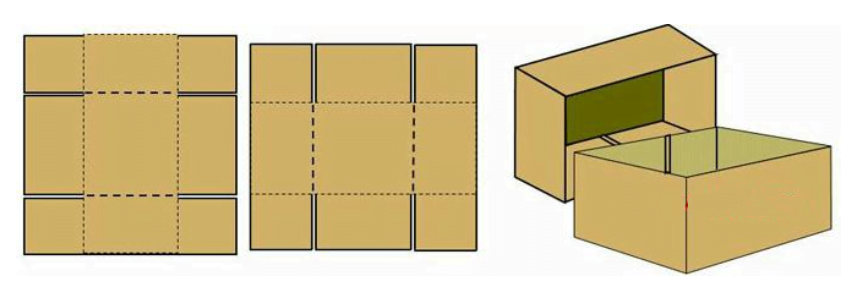

- Composite half wing box: The two half-wing boxes fit together. A combination of half-slotted boxes.

- Telescopic Box(partial fit): The cover is partially fitted.

- Tray: Single sheet cardboard, crimped and grooved or die-cut. Commonly used in the packaging of canned or boxed products.

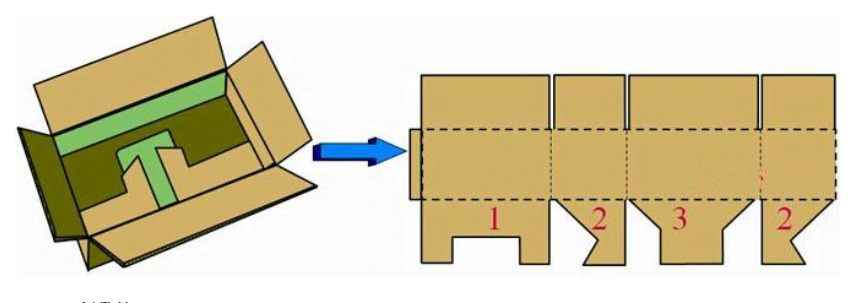

- Blessing box:Usually composed of 3 pieces, the bottom is connected together, high pressure resistance and use less material, often used in poultry, meat, clothing, or ice cream, etc.

- Self-locking bottom carton:The top is the same as the ordinary slotted box, and the bottom is designed to be locked and formed by itself. Mainly used in toys, tapes, small packaged food, etc.

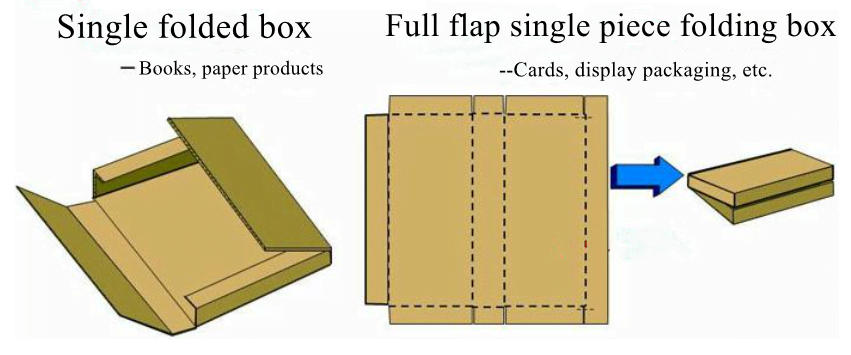

- Folding box: Single piece of cardboard (with creases and slots), folded to form a box.

- Lock bottom folding carton:The top is the same as the ordinary slotted box, and the bottom is designed to be bonded and locked.

- Lock bottom single plug-in folding box:Commonly used in clothing, toys, high value items, glassware, etc. Available in single or combination packs (inner boxes).

- Display racks in different designs

- Lining:Partitions, guardrails, partitions, etc., mainly play the role of separation and reinforcement.

- Special box type

(1) Heavy-duty packing carton

(2) Other special-shaped packaging cartons

As a professional manufacturer of carton machinery, we have the most advanced carton machinery and technology. Our carton machinery can produce various types of corrugated boxes above, including ordinary corrugated cartons, corrugated cardboard, color-printed cartons, etc., to meet your different needs.

We have a professional R&D team and technicians, constantly innovating and developing more high-quality and durable carton machinery products. Our corrugated box machinery has the advantages of high automation, fast production efficiency and easy operation, which can greatly improve your production efficiency and reduce costs. At the same time, we pay attention to after-sales service. Whenever you have any questions and needs, we will solve them for you in time. If you are looking for a high-quality carton machinery supplier, please contact us, we will wholeheartedly provide you with excellent products and services!