How To Choose A Right Folder Gluer Machine

The folder gluer machine is an essential machine in a carton factory. Looking around us, many cartons are made of different shape of cardboard by sticking. So, for carton factories or end users who want to buy a folder gluer, among the many models, how to choose a suitable machine?

When purchasing a folder gluer, you should proceed from your own actual situation and choose a folder gluer according to the production capacity, the thickness and width of the processed cardboard, and the type of carton.

Automatic Carton Folder Gluer Machine:

Type One: First of all, the output of the factory needs to be considered. How big is your factory? What is the daily or monthly carton output? What are the daily working hours? This is very important. If you produce few varieties, large batches, standard-shaped cartons, a spacious workshop, and high-speed printing and slotting units, then a fully automatic carton folder gluer is a good choice. This auto carton folder gluer machine produces quickly and efficiently and saves labor costs. , can help you greatly improve production efficiency.

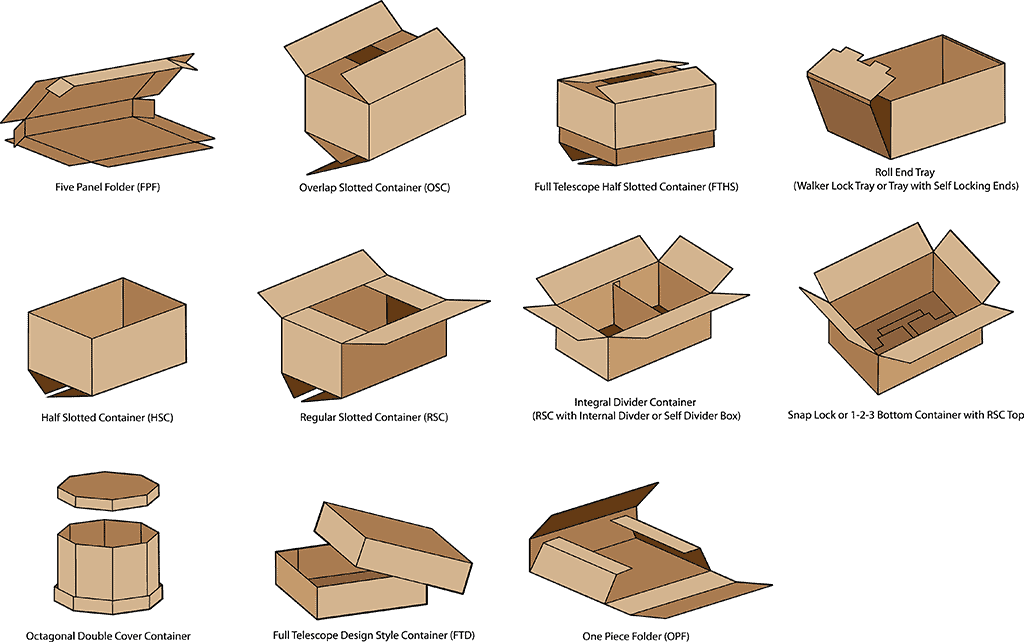

Type Two: If you produce many varieties, large output, and special-shaped cartons, our fully automatic folder-gluer specially for special-shaped cartons can meet your needs;

Advantage of the automatic carton folder gluer machine:

The processes from cardboard feeding, folding, gluing, pressurizing, shaping, bundling and other processes are all completed automatically by the machine at one time. Its characteristics are manpower saving and high efficiency. At present, some large carton factories and factories with higher production efficiency requirements will choose this style.

Semi-automatic carton folder gluer machine:

Type one:

If it is a small and medium-sized carton factory with complex product structure and low output requirements, then it is definitely right to choose a semi-automatic pressing type box gluer;

Advantage of the semi-automatic carton folder gluer machine:

This kind of box gluing machine is composed of an automatic feeding part, a polishing and gluing part, a conveying part, and a manual folding and pressing part. Workers fold and press them manually, and then put them into the pneumatic working part for compression after reaching a certain number. Its characteristic is that the feeding part automatically feeds quickly, but it cannot feed folded cardboard and can only feed flat sheets. The feeding part of this box gluer is similar to the leading edge paper feeding structure. It is fed by special tapes, rollers, etc. At the same time, it can also complete the gluing of two pieces of cardboard into a box, and can complete the gluing of special cartons such as special-shaped cartons and partial-mouth boxes. Its grinding and gluing work part can very accurately roughen and glue the parts that need to be bonded, and you can also use the nozzle equipped with the machine to locally spray glue on special-shaped boxes. The maximum bonding size of the machine: 1800x1100mm, the minimum bonding size 200x200 mm.

Type Two:

If it is a small and medium-sized carton factory, the cartons are standard-shaped cartons, and the output requirements are not high, then our semi-automatic carton folder gluer machine is your best choice;

Advantage of the semi-automatic carton folder gluer machine:

This type of machine is widely used and is mainly used for folding, gluing, shaping, conveying, pressurizing, counting, drying and other functions of cartons. This semi-automatic carton gluing machine is suitable for outer packaging boxes with standard folding flaps. , and the cartons must be pressed along the corrugated “fold line”, otherwise the stuck cartons may produce waste products. This machine is very suitable for cardboard after die-cutting. The maximum processing size of this machine (length + width) × 2: 2460mm;Minimum processing size (length + width) × 2: 340mm;mechanical speed: 35~40 meters/min.

So, now you know which machine is more suitable for your needs?