5 Ply Corrugated Cardboard Production Line

Product Description:

The high speed 5 ply corrugated cardboard production line is designed for manufacturing double-wall corrugated board, consisting of liner + medium + liner + medium + liner. Compared with 3-ply board, 5-ply corrugated board offers higher strength, better compression resistance, and improved durability, making it ideal for heavy-duty packaging and long-distance transportation. It is widely adopted by carton factories and board plants that require medium to high-grade corrugated board.

Features & Functions:

Double-wall structure: Capable of producing various flute combinations such as BC, AC, and BE flutes, ensuring both strength and smoothness.

Higher capacity: Suitable for large-scale production of strong corrugated board to meet bulk order demands.

Flexible configuration: Available in single or double facer setups, with interchangeable flute rolls.

High automation: Equipped with auto splicing, automatic web alignment, thin blade slitting, NC cutting, and stacking systems.

Stable quality: Ensures strong bonding, flat surface, and excellent performance for printing, die-cutting, and gluing.

Main Specifications:

Working Width: 1800 mm, 2000 mm, 2200 mm, 2500 mm (optional)

Design Working Speed:

Medium speed: 120–150 m/min

High speed: 180–250 m/min

Flute Combinations:

BC, AC flutes for heavy-duty packaging

BE flute for strength and fine printing

Other combinations available upon request

Paper Grammage: Liner: 150–250 g/m², Medium: 100–180 g/m²

Steam Pressure: 0.8–1.3 MPa

Installed Power: 300–450 kW (depending on configuration)

Line Length: approx. 55–100 meters (depending on speed & setup)

Main Configuration:

| No | Machines list | Quantity |

| 1 | Hydraulic mill roll stand –support two dia.1500mm paper roll –including track and trolley for carry paper roll –pneumatic brake and spring clutch | 5 set |

| 2 | Preheater (RG) ø600mm | 4 set |

| 3 | Cube type fingerless single facer (SF-320) –corrugating roller dia.320mm,with a drum. –press roller dia.320mm. With drum. | 2 set Flute type can be according to client’s requirement |

| 4 | Overhead bridge –double vacuum tension control –electric paper way control | 1 set |

| 5 | Triplex preheater (RG) Ø600mm | 1 set |

| 6 | Duplex glue machine GM-B — glue roller embossed and chrome plated | 1 set |

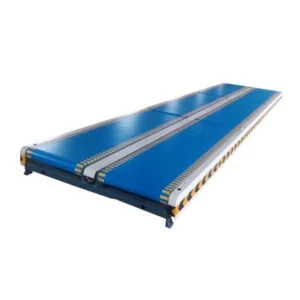

| 7 | Double facer (SM-S) –including quality cotton belt 1set –including drive roll stand –including 16 pcs(16 x 600mm) heating plates- | 1 set |

| 8 | Full electric adjust thin blade slitter scorer –5 set slitter knives and 8 set scorer wheel –automatic adjust blade& scorer moving | 1 set |

| 9 | N. C cut-off (computerized order change) –helical knife –with full servo computer system Keb main driver | 1 set |

| 10 | Automatic counting paper sheet delivery | 1 set |

| 11 | Glue making machine | 1 set |

| 12 | Internal steam pipe system | 1 set |

| 13 | Internal electric system | 1 set |

| 14 | Compress air system | 1 set |

Applications:

The 5 ply corrugated cardboard production line is mainly used by board plants and carton factories to produce heavy-duty corrugated board for demanding packaging needs.

Typical applications include:

Industrial heavy packaging: Appliances, furniture, motorcycles, bicycles, and other bulky goods.

Beverage and alcohol packaging: Beer, wine, and other transport-intensive products.

Agricultural and food transport: Fruits, vegetables, and cold-chain logistics.

Export packaging: For goods requiring high compression strength and long-distance transport protection.

E-commerce & logistics: Heavier shipment boxes for warehouse and distribution.

Compared with 3-ply board, 5-ply corrugated board provides greater stacking strength, impact resistance, and reliability, making it essential for medium to large carton production and heavy-duty export packaging.