2024 Must-See:Corrugated Cardboard Making Machine

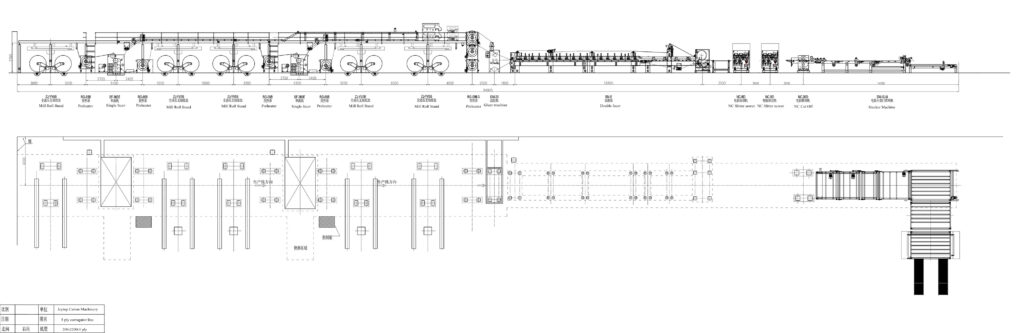

Corrugated cardboard making machine is also called corrugated cardboard production line. It is a production system composed of a series of equipments used to process base paper into corrugated board.

The main machine components of the corrugated cardboard making machines are:

1. Mill Roll Stand: used to support and feed base paper.

2. Single facer machine (corrugator): press base paper into corrugated cardboard.

3. Gluing machine: apply glue to corrugated core paper.

4. Double facer machine: laminate the surface paper with the glued corrugated core paper.

5. Dryer: dry the glue to solidify the cardboard.

6. Slitting and creasing machine: longitudinally cut and crimp the cardboard.

7. Cross-cutting machine: cut the cardboard horizontally into the required size.

8. Stacking machine: neatly stack the finished corrugated cardboard.

9. Conveyor bridge: plays the role of connecting and conveying between various machines.

10. Paper splicer: It can realize fast, smooth and automatic paper splicing of base paper without stopping the machine, ensuring the continuity of production.

11. Production management system: can realize scheduling planning, equipment monitoring, personnel management, cost accounting, order management, etc. for the production line to improve the production management level and competitiveness.

12. Temperature control system: accurately control the temperature of each link in the production process to ensure the quality and production efficiency of the cardboard.

13. Whole-plant logistics system: covers a series of logistics activities such as the supply of raw paper and other materials, the circulation in each production link, and the storage and transportation of finished corrugated cardboard to ensure the efficient and orderly operation of the production line.Temperature control system: accurately control the temperature of each link in the production process to ensure the quality and production efficiency of the cardboard.

Production process of the corrugated cardboard making machine

How to choose and buy Corrugated cardboard making machine?

Generally, companies with strong financial strength and new factories will purchase corrugated cardboard making machine in a whole line, and such companies often have relatively definite sales and long-term stable customers. The various equipment purchased must be matched. If a wide-width, high-speed corrugated cardboard production line is purchased, it must be equipped with high-speed carton forming equipment. If there is no powerful cardboard consumption, the corrugated cardboard production line is not able to play its own functions, and a lot of investment will be wasted.

- Selection of single facer on the carton production line.

When buying a single facer machine, if the speed is fast and many fluting shapes are required, you should consider choosing a corrugated roller with a quick-change structure. If you choose a positive pressure card machine, it is easier to replace the corrugated roller, which can reduce failures and downtime for maintenance. Generally, a set of corrugated rollers for single-sided machines needs to be purchased as spares. When choosing a corrugated roller, you should mainly consider the characteristics of the corrugated substrate, the accuracy of the corrugated teeth, the hardness and the wear resistance of the coating.

At present, there is a thermal sprayed tungsten carbide corrugated roller on the market, which is more durable, with a hardness of about HV1200 and a service life of three or four times that of ordinary hard chrome-plated rollers. Although the price is more expensive than ordinary corrugated rollers, it is still worth considering from the perspective of long-term benefits and product quality.

- Purchase of paper splicing machine on corrugated cardboard making machine.

The paper splicing machine is a supporting equipment of the corrugated production line. If you purchase a paper splicing machine with excellent performance, you can achieve a 100% success rate of paper splicing even when the corrugated production line is running at a high speed.

When purchasing a paper splicing machine, a paper splicing machine with a production speed corresponding to the speed of the production line should be configured according to the characteristics of the entire production line. Do not configure a low-speed automatic splicing machine on a high-speed production line, such as a 120m/min splicing machine on a 200m/min production line. This will not only greatly affect the production efficiency, but also affect the positioning accuracy and constant tension control , Making it difficult to guarantee product quality.

- The purchase of preheating cylinder on the corrugated cardboard making machine.

On the one hand, the preheating cylinder can increase the temperature of the base paper and activate the fiber molecules; on the other hand, it can quickly evaporate the excessive moisture in the base paper, which helps to improve the forming hardness and bonding quality of the corrugated board. And it can effectively avoid the warpage of the cardboard. Therefore, the preheating cylinder should be selected to have the largest wrap angle adjustment capability, so that it can be controlled and adjusted to a greater extent to balance the moisture of the base paper and improve the strength of the corrugated board.Purchase of conveyer bridge and their devices on the carton production line.

- Purchase of conveyer bridge and their devices on corrugated cardboard making machine.

The paper conveyer bridge can make the formed single-faced corrugated cardboard dry in a natural state. A certain amount of corrugated cardboard is piled on the conveyer bridge, which helps to buffer the cardboard and better balances some problems caused by the inconsistency of the speed of the single facer and the double facer due to the existence of certain unfavorable factors. The paperboard tension control and adjustment device of the paper conveyer bridge should adopt electric splints and frequency converters to control the air volume, which can correct the warpage of the paperboard and ensure the quality of the paperboard.

- The purchase of NC thin blade slitter scorer on the corrugated carton production line

At present, there are two types of NC thin blade slitter scorers on the market, mainly vertical and desktop. The vertical NC thin blade slitter scorer can be used in conjunction with the corrugated cardboard production line. The desktop NC thin blade slitter scorer is suitable for independent stand-alone use.

These two structures are further divided into three types: ordinary type, improved type and computer digital control high-end type. The ordinary type slitter scorer has only one set of thin knives and crimping wheels, which are driven by a chain and manually adjust the knife line; the improved vertical type is composed of two sets of upper and lower thin knives and crimping wheels, which can be turned over 360 degrees freely. The wire wheel can be hydraulically lifted or manually adjusted and controlled, and it is driven by gears.

The desktop improved type NC thin blade slitter scorer has been lengthened and improved on the paper feeding positioning baffle, and a paper guide wheel is installed at the rear of the slitting knife; the high-end type adopts a computer digital control device and has a quick adjustment of the cutting line , Automatic correction and other advantages. When purchasing a thin blade slitter scorer, you should check whether the paper guide wheels, gears, crimping wheels, blades and grinding wheels are abnormal; whether the machine is running smoothly, whether there are abnormal phenomena such as noise, chatter, crimping wheels, Whether the surface of the cutting blade is smooth or not.

Self-combination purchase of corrugation machine

Self-combination purchases are generally chosen out of not wanting to invest a lot of money, but also hoping to obtain a corrugated cardboard production line with suitable quality, price and performance. Purchasing in this case is generally because the original tile line can no longer meet the needs of production or the investment of a new plant is to reduce risks. The supplier of the cardboard production line will be configured as needed, and is a solution that many corrugated cardboard machine manufacturers are willing to choose.

Upgrade purchase of original carton box making machine

The original equipment upgrade procurement method is aimed at those who do not want to purchase new equipment, through the transformation of the original equipment, such as adding two or three paper splicing machines to increase the average speed and production efficiency; the steam pipeline is modified to quickly supplement heat energy and reduce energy consumption, or Adding glue-making equipment to improve the adhesion of the cardboard, etc., this procurement method has little impact on production, less capital investment, and benefits in a short time, which is an ideal way to purchase.

If you have need of the corrugated cardboard making machine, contact with us Now: