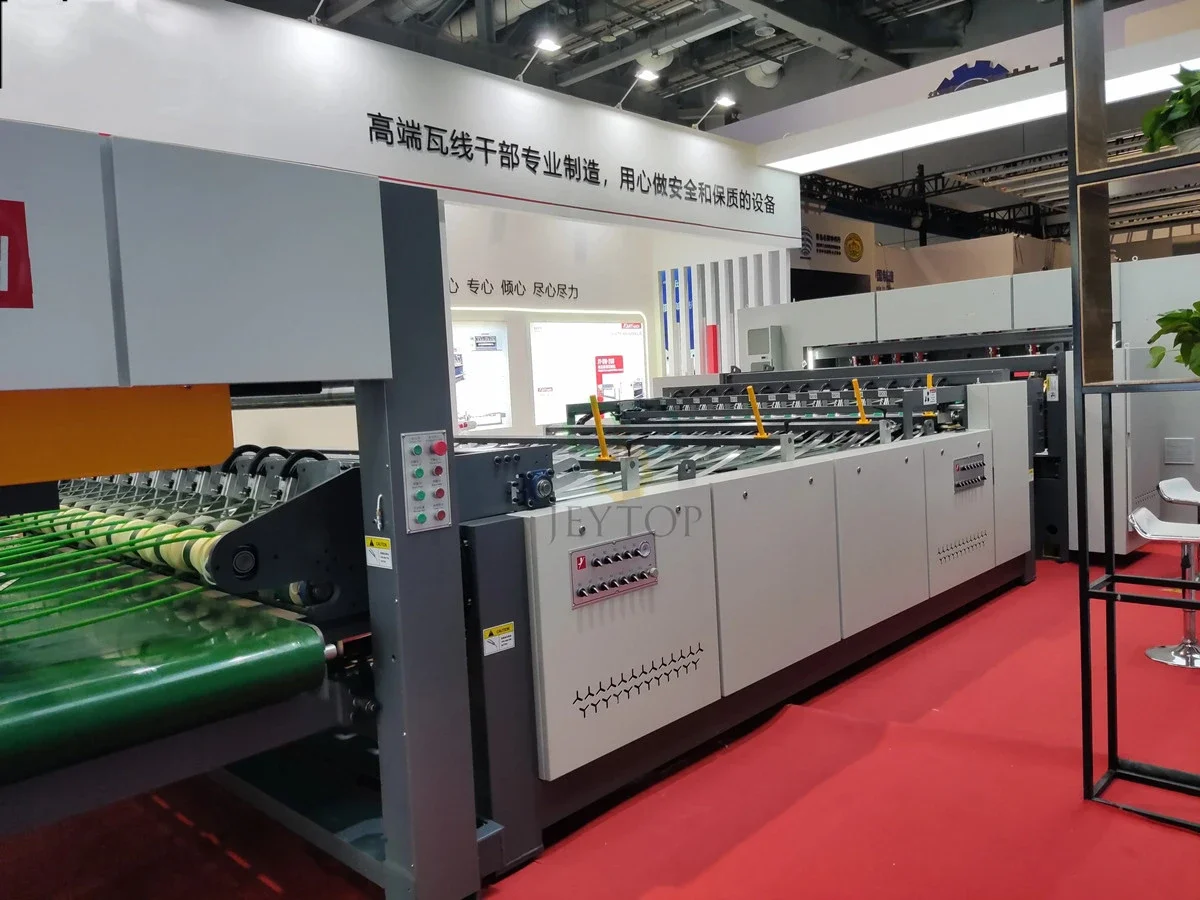

Characteristics of the 2 Ply Corrugated Cardboard Cutter Stacker Machine:

- Constant tension cardboard conveying, the conveying speed is strictly synchronized with the speed of the single facer machine.

- Alloy steel thin blade for longitudinal cutting, automatic sharpening, long blade life, and high slitting quality.

- The longitudinal cutting knife is independently servo-controlled, and the order arrangement is fast, accurate and reliable.

- The longitudinal cutting speed is controlled by a variable frequency motor and inverter, and is adjusted synchronously with the cardboard speed.

- When changing orders, the left and right waste suction ports are electrically adjusted following the edge knife.

- The cross-cutting box body is made of high-quality castings, strictly aging treatment, and precision processing, and the equipment operates stably for a long time.

- The alloy steel seamless steel pipe spiral knife shaft has economical processing, dynamic balance correction, high rigidity and small inertia.

- The cross-cutting knife adopts the German Kobe AC servo controller.

- The 2 Ply Corrugated Cardboard Cutter Stacker Machine is used as dry part of automatic 2 ply corrugated cardboard production line.

Technical Parameter of 2 Ply Corrugated Cardboard Cutter Stacker Machine:

- Effective width: 1600-2200mm

- Maximum speed: 150m/min

- Number of longitudinal cutting knives: 5

- Minimum longitudinal cutting width: 180mm

- Arrangement time: 3-8s

- Arrangement accuracy: 0.5mm

- Cross-cutting length: 300~9999mm

- Cross-cutting accuracy: 1mm (uniform speed)

- Stacking height: 250~600mm (select according to customer needs)

- Maximum cardboard stacking length: 1600mm

- Main machine power 12.5KW

- Paper feeding motor power 1.5KW

- Basket motor power 3KW

- Horizontal output motor power 0.75KW

评价

目前还没有评价