3 Ply Corrugated Board Production Line

The 3 ply corrugated board production line is suitable for large number of highly automated production, and can produce high quality cardboard.

Description

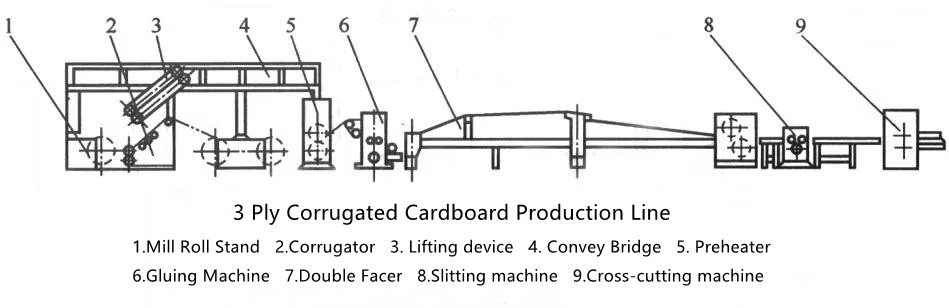

3 Ply Corrugated Board Production Line

The three-layer corrugated cardboard production line is the key production equipment of corrugated cardboard production enterprises, including wet part, dry part, production management system and other important components. The 3 ply corrugated cardboard production line includes the following machines: electric/hydraulic shaftless mill roll stand, preheater, single-facer, overhead conveyor bridge, double preheater, gluing machine, double-facer, thin blade slitter scorer machine, cross-cutting machine, CNC cutting machine, stacking machine, etc.

Working principle: The three-layer corrugated cardboard production line is a production line that consists of processes such as corrugation, gluing, bonding, paper separation and pressing, cross-cutting into three-layer corrugated cardboard of required specifications, and finally stacking and output.

Production flow chart:

Characteristic:

1) Cardboard box assembly machine, Work continuously, is suitable for a large number of highly automated production, and can produce high-quality corrugated boxes and corrugated cardboard.

2) Higher productivity, better paperboard quality, using a central control system, simple and convenient operation, convenient repair and maintenance, reliable and safe, and greatly reduced the labor demand.

3) The latest energy-saving mode is adopted, which reduces energy consumption by 60%. Compared with steam heating, it can effectively reduce costs.

Technical Parameter:

| Working width | 1400-2500mm(as requirement) |

|---|---|

| Working speed | 80-250 m/min |

| Flute type | A/C/B/E/F(as customers’ requirement) |

| Heating method | Steam/Oil/Liquefied Gas/Electric |

| Top paper | 100—250g/m2 |

| Core paper | 100—250g/m2 |

| Power supply | 380V/50HZ (Can be as requirement) |

| Equipment operation position | According to the user to determine the transmission plant set left or right position |

Main Confirguration List:

Hydraulic shaftless mill roll stand | Set | 3 | Main shaft ¢242mm, hyperbolic heavy-duty rocker arm, tooth-type paper clamping head, multi-point brake, hydraulic drive lift, left-right translation, centering. The length of the guide rail is 6000mm, and the middle plate is welded. |

Paper trolley | set | 6 | |

Top paper preheat cylinder | Set | 1 | Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated area of the paper within 360°. |

Core paper prehear cylinder | Set | 1 | Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated area of the paper within 360°. |

Fingerless type single facer | Set | 1 | The corrugated main roller is ¢320mm, and the material is 48CrMo alloy steel. Tungsten carbide treatment, tile roller module type hoisting in groups. Airbag ballast structure, HRB main bearing, PLC automatic control glue, man-machine interface touch screen, automatic shutdown and pressure relief when paper is broken, steam heating mode. |

Double preheater | Set | 1 | Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated area of the paper within 360°. |

glue machine | set | 1 | The diameter of the glue roller is 268mm. Each layer is driven by an independent frequency conversion motor, and PLC adjusts the glue gap and man-machine interface. |

Conveyor bridge | set | 1 | The main beam is 200mm channel steel, and the independent frequency conversion motor drives the paper pulling and conveying, and the suction tensioning. Electric deviation correction. |

Double facer | set | 1 | Frame 360 mm national standard channel steel, hot plate 595 mm *14 pieces, intensive roller design structure. Pneumatic lifting, temperature display, side door, frequency conversion motor. |

Lifting thin knife slitting and creasing machine | set | 1 | Tungsten alloy blade, five-knife eight-wire type, electric knife adjustment, electric wire adjustment. Electric traverse. |

Computer spiral knife Crosscutting machine | set | 1 | Full AC servo control, energy storage brake, spiral knife structure, oil-immersed gear drive, 10.4 inch touch screen display. |

Three-section right angle stacker | set | 1 | Three-stage frequency conversion conveying, automatic counting and stacking discharge, imported high-strength belt output, and standard conveyor rack on the paper side. |

Glue station system | set | 1 | The pipeline customer shall prepare by himself. The glue making device is composed of a carrier tank, a main tank, a storage tank, a glue feeding pump, and a glue returning pump. |

Air source system | set | 1 | The customer’s own gas source. |

Steam system | set | 1 | Including steam components such as pipeline valves, traps, and meters in the equipment, the customer shall prepare the heat source and pipeline. |

- This 3 layer corrugated cardboard line is suitable for mass automated production.

- The corrugated cardboard produced meets the standards, has high production efficiency, good cardboard quality, centralized control, convenient operation and maintenance, safe and reliable.

- This 3 ply corrugated production line greatly reduces the labor intensity of workers. Today’s economical products are suitable for large and medium-sized carton factories.