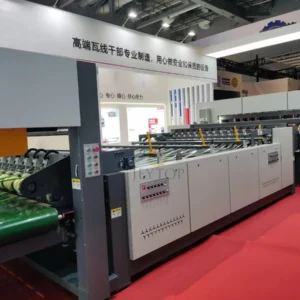

Characteristics of the Fingerless Single Facer SF280:

- The transmission reduction gearbox adopts oil-immersed lubrication, which reduces noise and ensures smooth operation. It uses universal joint transmission and has an independent power source.

- The corrugating rolls, pressure rolls and gluing rolls are adjusted pneumatically.

- The cardboard is conveyed by means of vacuum adsorption and is equipped with an air volume control system. Under high-speed operation, it can keep the corrugated contour of the lower roll stable.

- The bearings of the corrugating rolls and pressure rolls use high-temperature lubricating grease.

- The gluing components adopt automatic circulating glue supply.

- The upper and lower corrugating rolls are made of high-quality 48CrMo alloy steel. After heat treatment, the hardness is HRC58°-60°, and the surface is ground.

- The surface of the gluing components is treated with a special reticulated pattern and is chrome-plated.

- The gluing width can be adjusted in electric or manual gears to adapt to the width of the paper.

- The gluing part can operate independently or can stop without independent operation. It is controlled by the frequency conversion of the main machine. (Optional)

Technical Parameter of Fingerless Single Facer SF280:

| Design speed | 100 m/min |

| Economic speed | 80 m/min |

| Effective width | 1400 mm-2500 mm |

| Corrugated roller flute | A/C/B/E/F or as your requirement |

| Max working steam pressure: | 1.0- 1.3 Mpa |

| Heating type | Steam, Electric or oil heating |

| Power requirements: | 380 V, 50 Hz or according to your requirement |

| Diameter of corrugated roller | 280 mm |

| Diameter of Press roller . | 285 mm. |

| Diameter of preheater roller | 300 mm |

| Diameter of Glue roller | 215 mm |

| Diameter of doctor roller | 105 mm |

Useage:

Fingerless Single Facer machine, Also known as corrugated single facer machine, Engineered for high-volume packaging lines, it leverages 48CrMo steel corrugating rolls and pneumatic glue control to produce 1400-2500mm wide corrugated sheets at 100m/min—ideal for food boxes, e-commerce cartons, and industrial packaging.

评价

目前还没有评价