Automatic Carton Stitcher

Full computer control,easy and simpleto operate;can store 800 orders;

Description

Introduction to each part:

1) Linked with the paper feeding section, frequency conversion speed adjustment, and the folding and paper feeding section pressure lines are adjusted synchronously.

2) Imported porous belts are used to transport cardboard, which are automatically folded and adsorbed throughout the process, effectively avoiding the phenomenon of skewing, slipping and stacking of paper during work such as weighted boxes, laminated boxes, glazing boxes, etc., making the whole machine more stable and efficient. .

1) This machine will have a shaping device at the rear of the folding section and before nailing the boxes. Before nailing the boxes, the folded cartons will be shaped and photographed again to ensure that the nailed cartons have no scissors.

2) The correction part is driven by servo motor.

1) The nail box machine head is made of special material, which is wear-resistant and not easily damaged.

2) The characteristics of this machine are that the machine head is directly driven by a servo motor, and the speed is stable and accurate.

3) The nailing line uses two 20kg large flat wire automatic wire feeding devices at one time to reduce the number of wire changes and improve production efficiency.

4) This machine can perform multi-functional operations such as single nailing, double nailing, and reinforced nailing on cartons.

5) The nailing speed can reach 800 nails/minute.

1) Complete carton stapling, pat, count, stack and output automatically.

Characteristics of The Automatic carton stitcher:

1. Full computer control, easy and simple to operate; It can store 800 orders;

2. Bottomless corrugated box with cover can be stapled (to be specified when ordering);

3. Take 3-5 minutes to shift the size, simple and quick;

4. Nailhead power for the servo motor, the mechanical speed:800 nails per minute.

5. The paper feeding part adopts front belt feeding to ensure that the cartons are not skewed.

6. There is a side flap device when feeding paper, which can make the paper feeding smoothly.

7. The paper feeding part adopts the servo motor to control, to ensure stable and accurate nail pitch;

8. This machine is designed with box shaping functions, ensure the scissors will not appear in the stitching;

9. The carton stitching machine can do single, double nails, strengthening the nail, completed at one time;

10. The cardboard stitcher machine can stitch 3 layer, 5 layer cartons (seven-layer need to be declared in advance when ordering);

11. The auto feeding carton stitcher has automatic counting and stacking quantitative output at the end.

12. The bundling part of this machine is optional.

13. The machine is with three functions; stick, stitch and sticking & stitching at the same time.

Main configuration of Automatic carton stitcher:

1. Servo motor, and inverter are Japan Yaskawa brand

2. PLC for the OMRON brand

3. The touch screen is Kunlun Tongtai, and the contactor is Schneider brand.

4. Photoelectric switches, proximity switches circuit breakers for Schneider brand.

5. Nailhead main parts manufacturing for the Japanese die steel; Cutting Blades, The bottom die for the German import tungsten steel Cylinder, Electromagnetic valve is Taiwan AIRTAC brand The whole machine is converted by precision CNC machining center;

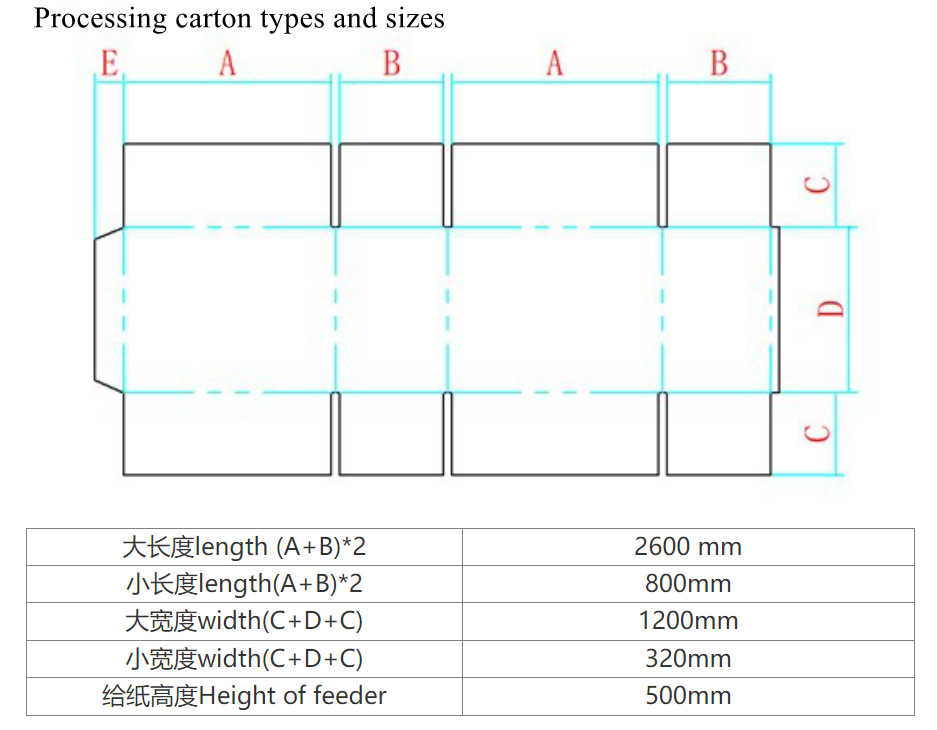

Technical Parameter of the Automatic carton stitcher:

| Nail head speed | 800 Nails / min |

| The minimum thickness of the board | 4 mm |

| The maximum thickness of the board | 12 mm |

| U nail internal width | 12 mm |

| Flat wire specifications | 17#(2.0x0.75) |

| Nail box inclination | 45 |

| The minimum distance of nailing | 30 mm |

| The motor power | 8.6 kw |

| The minimum stack width | 300 mm |

| The maximum stack width | 1600 mm |

| The minimum stack length | 250 mm |

| The maximum stack length | 250 mm |

| Speed | 120 m/min |

Useage of the automatic carton stitcher:

It is suitable for large and heavy cartons, used for the packaging of household appliances and other products, which can ensure that the cartons have a large bearing capacity and the internal products are not bumped.

Picture of stapled carton box: