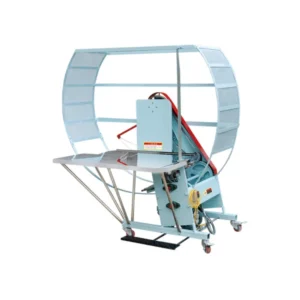

Characteristics of the Semi-auto Carton stitcher machine:

- A dual-purpose machine for simple forming carton,double forming carton,irregular carton.

- The size is full electrically controlled and it can be changed the size in 2-3 min.

- The strengthened,single,double nailing can be finished in a lump.

- Auto counting,after stacked,it will be auto packing. Available for lagre carton,and nail-feeding is high speed and high efficiency.

- Nailing distance is free adjustable between 30-120 mm,set by computer.

- It can make special box without cover.

Technical Parameter of the semi-auto carton stitcher machine:

| Max(L+W)*2 | 2460mm |

| Min(L+W)*2 | 606mm |

| Max(W+H)*2 | 1515mm |

| Min(W+H)*2 | 300mm |

| Height of feeder | 900mm |

| Power | 6HP |

| Size | 2800*2600mm |

| Speed | 450 stitches/min |

| Stitching pitch | 30-100mm |

| Number of stitching | 1-99 stitches |