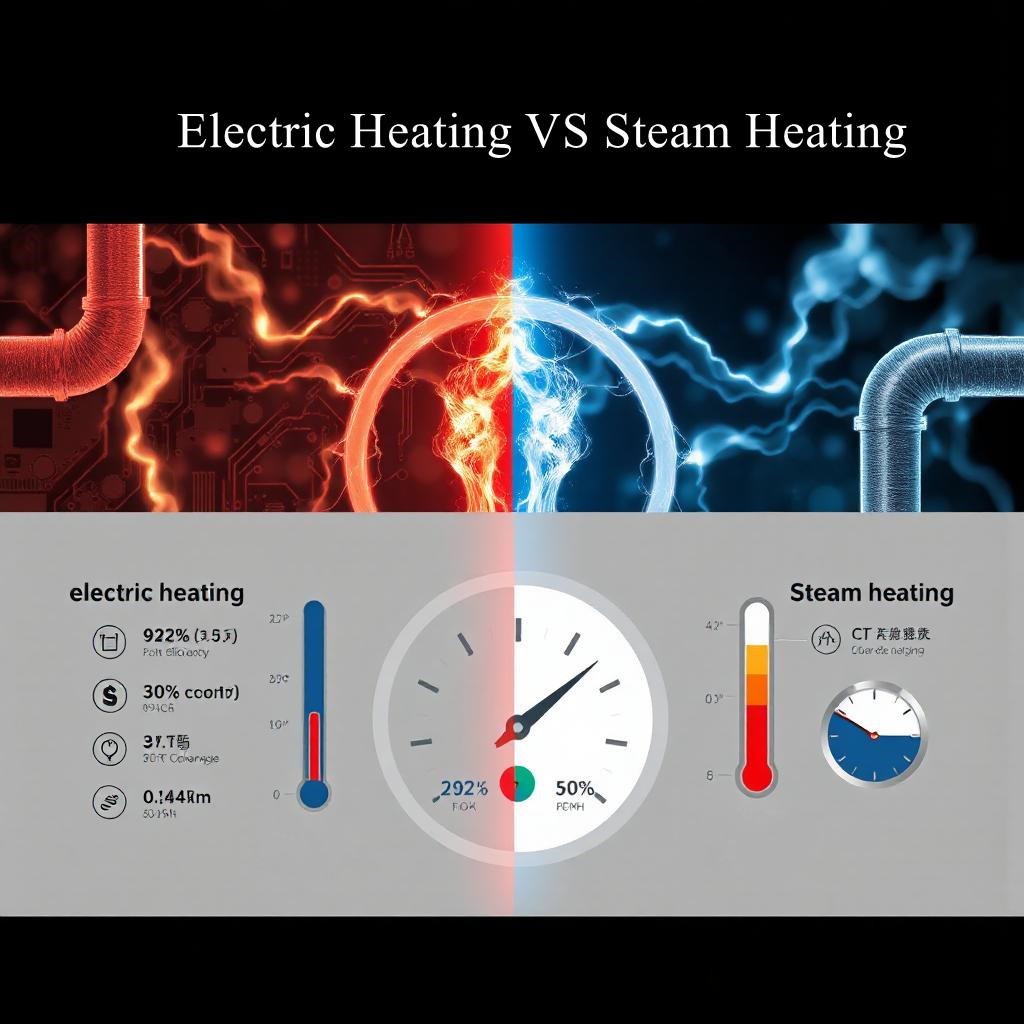

In Single Facer Heating, the choice between electric heating and steam heating can affect equipment output, investment costs, and long-term operational efficiency. Below are the main differences in output and investment costs between the two:

1. Heating Methods: Electric Heating vs. Steam Heating

Electric Heating

- Principle: Electric heating elements (such as electric heating tubes or wires) directly heat the surface of the corrugated rollers, typically using resistance heating or infrared heating technology.

- Investment Cost: Electric heating systems are generally more cost-effective in terms of initial investment because they don’t require additional steam boilers, piping systems, or steam control equipment. They are easier to install and maintain, with lower ongoing costs.

- Impact on Output: Electric heating offers faster and more precise temperature control. However, its heating efficiency may be slightly lower than steam heating, especially in large-scale production, which could impact overall production speed. Generally, electric heating is suitable for small to medium-sized production lines.

Steam Heating

- Principle: Steam is generated by a boiler and transmitted through pipes to heating plates or elements inside the corrugated rollers, indirectly heating the roller surface.

- Investment Cost: Steam heating systems require higher initial investment due to the need for a boiler, piping systems, steam control equipment, and booster pumps. Additionally, installation and maintenance costs for steam systems tend to be higher. Boilers and related equipment require extra space for installation.

- Impact on Output: Steam heating can provide a larger amount of heat in a shorter period and maintain a consistent high temperature, making it more efficient for handling larger production volumes. It is ideal for large production lines, helping to increase overall output.

2. Differences in Output and Efficiency

- Electric Heating: Suitable for small to medium-sized production lines. It has slower heating speeds, which can impact production efficiency, especially in cases where rapid temperature changes are needed. However, for lower to mid-speed production lines, electric heating is sufficient and offers high stability.

- Steam Heating: Best for high-output production lines. It maintains a constant high temperature, enabling faster heating speeds and higher temperature control precision. For plants requiring high-efficiency, high-speed production, steam heating is the better choice.

3. Long-Term Operation and Maintenance

- Electric Heating: The electric heating system is relatively simple, with low maintenance costs. It only requires regular checks on the condition of the heating elements. Energy consumption is typically higher, but there are no concerns about potential issues in steam systems, such as pipe leaks or boiler failures.

- Steam Heating: Steam systems require more maintenance, including boiler upkeep, pipe cleaning, and steam pressure control. Steam consumption is higher, leading to higher energy costs over time. However, steam heating provides more precise and uniform temperature control, making it better suited for high-load, long-duration production.

4. Summary

- Investment Costs: Electric heating systems are more economical, ideal for businesses with lower initial investment budgets.

- Output: Steam heating is better suited for companies that require higher output, more precise temperature control, and higher continuous production capacity.

- Long-Term Operation: Electric heating is easier to maintain and is suitable for small to medium-sized production; steam heating is best for large-scale production but requires more maintenance and incurs higher energy costs.

If customers have specific output requirements or budget constraints, they can choose based on these differences. You can also recommend the appropriate heating method based on the customer’s production needs.

In our corrugated cardboard production lines, whether you choose electric heating, steam heating, or other heating method, we can customize the production line to meet your specific needs. We will provide detailed information about power and thermal capacity requirements based on your chosen heating method and output demands. Just let us know your preferred heating method and the production output you’re aiming for, and we will recommend the most suitable production line for you.

By partnering with Jeytop, you can enhance your production efficiency and enjoy worry-free operations, leading to higher output and improved overall performance.