Characteristics of the 2 Ply Single Facer Corrugated Line:

Our company specialize in produce 2 ply corrugated cardboard production line, we have width from 1400 mm-2500 mm is available.

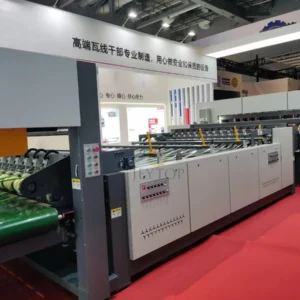

This production line is a semi automatic production line consists of mill roll stand, corrugation machine, reel sheet cutter. It can make paper roller to corrugated cardboard and cut it to required size, it has characteristics of advanced process, high efficiency, available to production in large amount, good work condition etc. It is the perfect equipment of the middle, small carton factory.

Main equipment list:

1. mill roll stand (electric and hydraulic shaftless is available)

2. single facer (electric / oil/ steam heating )

3. Sheet cutter with stacker

Technical parameter of 2 Ply Single Facer Corrugated Line:

| Product Name | 2 Layer Single Facer Corrugated Line | Style | semi automatic |

| Brand | JEYTOP | Effetive width | 1400/1600/1800/2000/2200/2500 |

| Design speed | 80-100 m/min | Place of Product | Hebei Province,China |

| Working speed | 60-80 m/min | heating method | steam or electric |

| Flute type | A/B/C/E/F/G | flute roller diameter | 280mm |