In the "battlefield" of corrugated carton production, surface paper blistering during high-speed operation, manual parameter adjustment when changing paper materials, and high energy consumption are persistent challenges. As an expert serving over 50 countries worldwide, Jeytop presents the Intelligent Pressure-regulating Heating Plate — a technological innovation that equips every production line with a "smart engine" to resolve manufacturing issues efficiently.

I. Is Your Production Line Struggling with These 3 Critical Pain Points?

❶ Quality Woes: Over 3% Defect Rate Leading to Customer Complaints

When customers receive warped cardboard sheets and lodge "quality non-compliance" complaints, the root cause often lies in uneven pressure from traditional heating plate.

▶ Industry Data: Issues like surface blistering and core penetration, common in conventional equipment, scrap 3%–5% of cardboard sheets monthly, wasting over 2,000 high-quality raw paper sheets.

❷ Efficiency Bottlenecks: 30-Minute Parameter Adjustment Halts Production

Switching to low-basis-weight paper requires manual pressure calibration, a trial-and-error process that can halt production for 30 minutes, wasting over 10 hours of productive time monthly.

❸ Cost Drain: 5% Higher Energy Consumption, $20,000 Annual Loss

Traditional heating plate "extensive" pressure control wastes over 5% of energy. For a medium-sized corrugated line, this translates to an annual electricity cost equivalent to purchasing a full-automatic paper splicer.

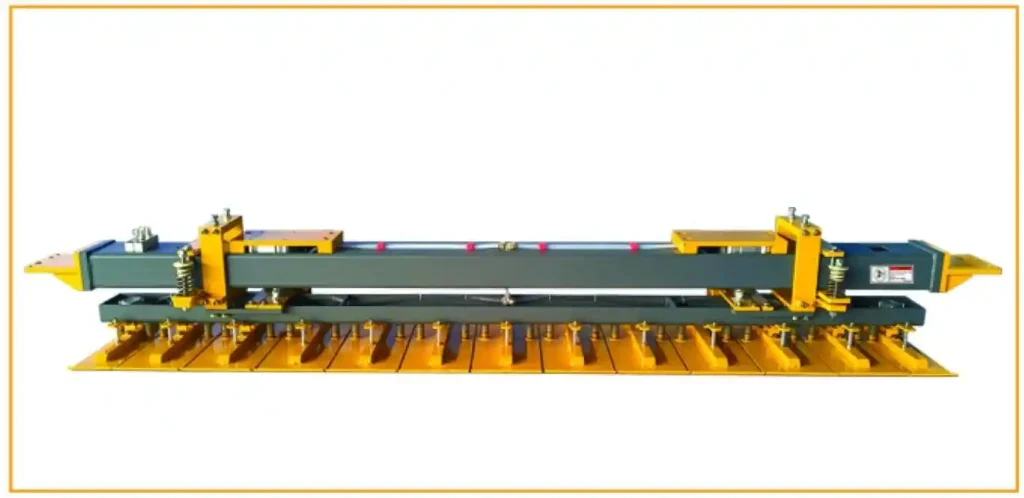

II. Jeytop Heating Plate: Redefining the "Core Heart" of Corrugated Lines

We reject mediocrity, aiming to create intelligent equipment that "understands production lines, adapts globally, and endures a decade of use."

❶ Intelligent Algorithm: Ultra-fast and Precise Pressure Regulation

- ✅ 0.1-second Response: Instantly identifies paper material, flute type, and speed (up to 350m/min), auto-adjusting pressure 10x faster than manual operations.

- ✅ Seamless Uniform Pressure: A patented seamless plate design ensures pressure error <0.5%, boosting board flatness by 40% and adhesive stability to 99%.

- ✅ Multi-mode Adaptability: Zero-pressure mode for low-basis-weight paper, continuous full-pressure mode (50% faster threading), and IoT connectivity for one-click order parameter synchronization.

❷ Energy Efficiency: Maximizing Every Unit of Energy

- ⚡ 5% Energy Savings: Micro-compressed air drive reduces energy consumption equivalent to 3 months' usage of 100 households.

- ⚡ 35-second Rapid Heating: Integrated with the whole-line temperature control system, it accelerates 105℃→175℃ heating 2x faster than traditional models, optimizing steam utilization by 30%.

❸ Durability: 15-Year Maintenance-free Operation

| Core Component | Material/Process | Performance Advantage |

| Main Beam | High-grade H-shaped steel | 20% enhanced high-temperature resistance |

| Heating Plate | 10mm 50# steel (heat-treated+plated) | HRC55 surface hardness, <0.1mm wear after 15 years |

| Drive Airbag | High-temperature-resistant material | 10-year maintenance-free, 40% cost reduction |

III. Why Do Over 50 Countries Trust Jeytop?

❶ Technological Leadership: 20+ Patents, High-speed Innovation

With over 20 independent patents, including in full-automatic paper splicers and heating plate, Jeytop pioneered stable 350m/min high-speed corrugated line operation.

❷ Global Service: International Certification, Localized Support

Products certified by CE, GOST, and sold in 50+ countries. Multilingual teams offer end-to-end services, while remote monitoring enables 7×24-hour technical support.

IV. Take Action Now: Get Your Tailored Intelligent Upgrade Plan

Whether you seek single-machine optimization or full-line integration, Jeytop offers no-threshold value services:

❶ Free Production Line Diagnosis

Submit your line information (paper type, speed, pain points) to receive a Pressure Balance & Energy Consumption Report identifying bottlenecks.

❷ Customized Solution Design

Our engineers will provide a tailored plan covering equipment parameters, ROI analysis, and local service networks, customized for high-speed stability, low-basis-weight paper adaptation, or energy savings.

❸ Free Technical Resources

Contact us to obtain the Corrugated Line Intelligent Upgrade Whitepaper, featuring 10+ international case studies and bilingual technical specifications.

Disclaimer

Technical data is based on laboratory tests and real-world applications. Actual performance may vary by equipment configuration, environment, and operation. For personalized calculations or certification documents, contact us via the official website.

About Jeytop Carton Machinery

Established in 2010, Jeytop is an integrated R&D, manufacturing, and global service provider for corrugated machinery. With 20+ patents and 350m/min high-speed technology breakthroughs, we offer full-process equipment for corrugated board and carton production. Certified by CE and GOST, our products empower packaging enterprises worldwide to enhance efficiency with "Made-in-China Intelligence."

🌐 Visit our website: [jeytop.com]

🔗 Follow on LinkedIn: [Yong Li---Jeytop Carton Machinery]

📧 Email: [jeytopmachinery@163.com]

📱 WhatsApp:[86-15230792110]