Heating is a critical factor in corrugated line heating systems. Proper heat control ensures consistent corrugated cardboard quality, stable adhesion, and smooth production at high speeds. The main heating options include steam heating, thermal oil heating, and electric heating. This article provides a professional comparison, equipment requirements for plants without existing heat sources, and practical recommendations for different production scenarios.

Steam Heating for Corrugated Lines

Advantages:

- Stable and proven technology for corrugated lines

- Fast heating and high temperature capability

- Widely standardized

Disadvantages:

- Requires a boiler house and related infrastructure

- Scaling, condensate losses, and trap failures possible

- Higher regulatory and maintenance requirements

If the customer has no steam system, additional equipment is required:

- Steam boiler (4–10 t/h depending on line capacity)

- Water treatment system (softening/demineralization)

- Condensate recovery system

- Steam pipelines, valves, and steam traps

- Boiler auxiliaries (feed water pump, burner, chimney, control system)

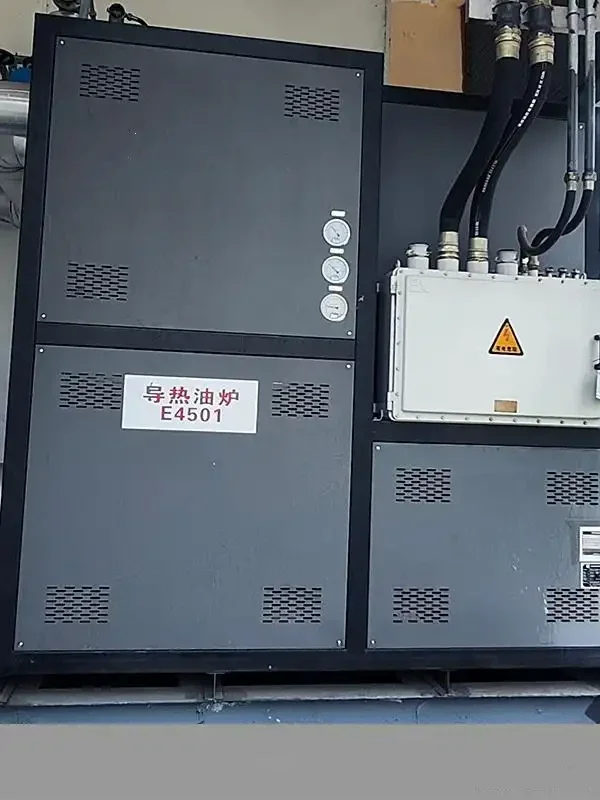

Thermal Oil Heating for Corrugated Lines

Advantages:

- Stable high temperatures up to 250°C under low pressure

- No condensate or water treatment required

- Ensures consistent board quality at high speed

- Lower regulatory burden

Disadvantages:

- Initial oil filling required (several tons)

- Leakage and oil aging must be monitored

If the customer has no thermal oil system, additional equipment is required:

- Thermal oil heater (1–5 MW depending on heat load)

- Circulation pump

- Expansion tank / storage tank

- Oil pipelines and valves

- Initial filling of thermal oil

- Safety and monitoring devices (temperature/pressure, relief valves, nitrogen protection)

Electric Heating for Corrugated Lines

Advantages:

- Simple installation and precise control

- No boiler or oil required

- Flexible local temperature adjustment

Disadvantages:

- High power demand at large scale

- Not economical for full production lines

If the customer chooses electric heating, they should ensure:

- Electric heating modules installed in preheaters and hot plates

- Electrical control system (temperature controllers, distribution cabinets)

- Sufficient factory power capacity

Case Study: 5-Ply / 1800 mm / 150 m/min / 300 t/day Production Line

For this line scale:

- No existing steam → Thermal Oil Heating is the preferred solution

- Existing mature steam system → Steam Heating is feasible

- Electric heating → Only for local or supplemental heating

Why Thermal Oil is preferred without steam:

- Quality consistency: Stable temperature reduces warping, bubbles, and bonding variations at 150 m/min.

- Operating cost (OPEX): No condensate or water treatment losses; maintenance is simpler.

- Safety & compliance: Low-pressure closed-loop system, easier to manage.

- Initial investment (CAPEX): No boiler room or water treatment infrastructure required.

- Response and speed: Fast temperature rise and recovery; easier to switch paper types.

When Steam is preferred:

- Existing boiler house, water treatment, and condensate recovery

- Steam serves other processes (humidification, cleaning)

- Local fuel prices favor boiler operation

Electric heating role:

- Not recommended as main source for this scale

- Can be used for local or precision heating

Comparison Table

| Factor | Thermal Oil (no steam) | Steam (existing) | Electric |

|---|---|---|---|

| Temperature stability | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ |

| Operating cost (OPEX) | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐ |

| Initial investment | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Safety / compliance | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

| Recommended scenario | New plants without steam | Plants with steam systems | Local heating only |

Conclusion

For new plants without existing steam: choose Thermal Oil Heating.

For plants with mature steam systems: Steam Heating is viable.

Electric Heating is suitable only for local or auxiliary heating.

Proper evaluation of infrastructure, operating cost, and production speed ensures stable operation, consistent quality, and long-term efficiency.