The corrugator belt is an indispensable part of the corrugated cardboard production line. It is mainly used to convey corrugated cardboard on the double facer, and ensure that they run smoothly in a high temperature and high humidity environment, and finally form high-quality corrugated cardboard.

The corrugator belt is woven with high-strength fiber or synthetic materials, and has the characteristics of wear resistance, high temperature resistance, corrosion resistance, etc. It can stably and accurately transport corrugated cardboard, ensure that the cardboard moves smoothly under high-speed operation, and is suitable for various types of corrugated machines such as BHS, TCY, Champion, JS, Hsieh Hsu, etc.

Charactericstics of the common edge corrugator belts:

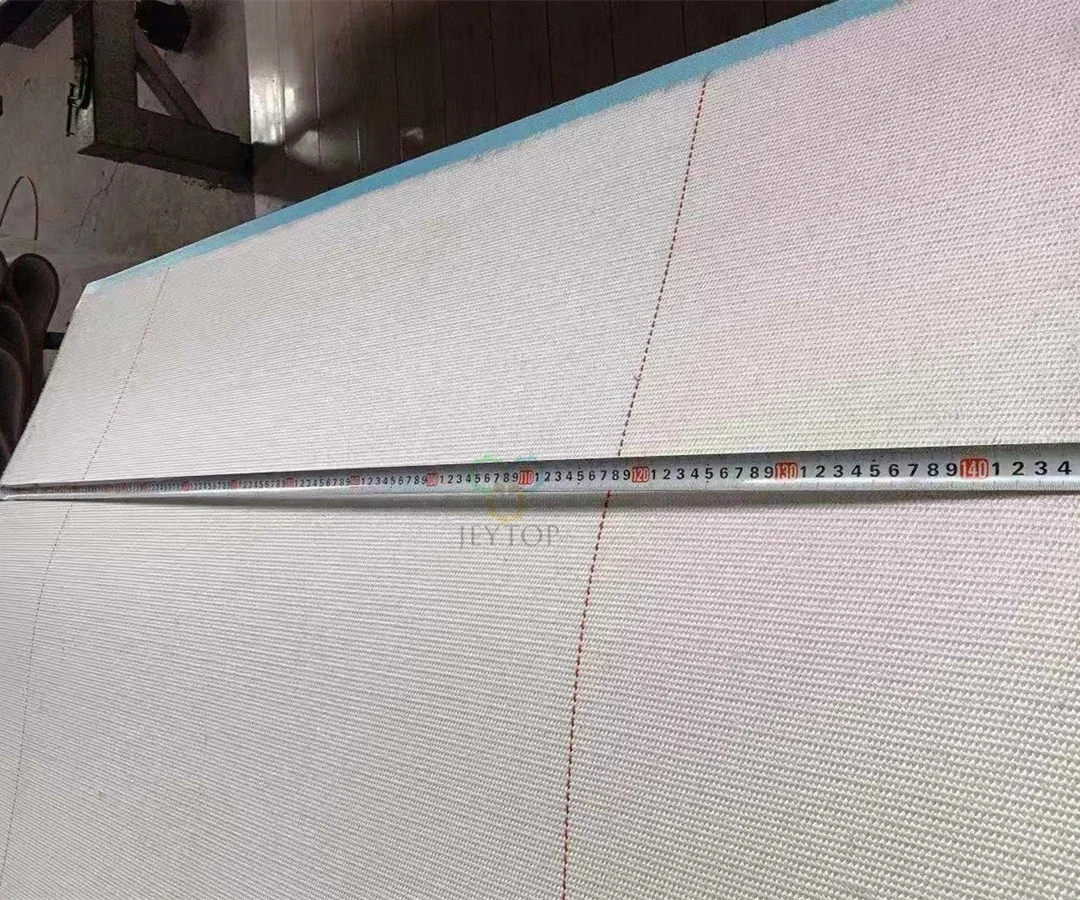

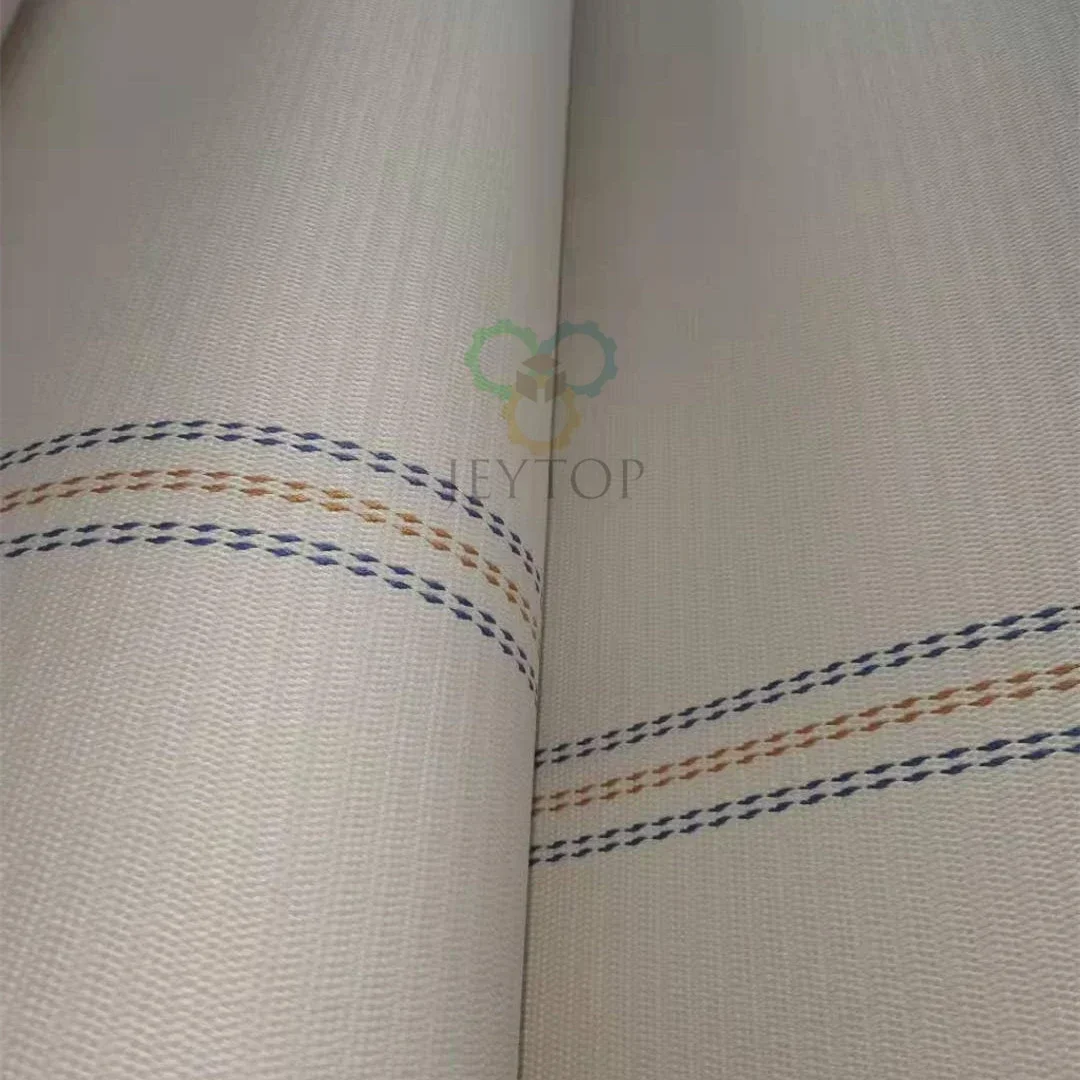

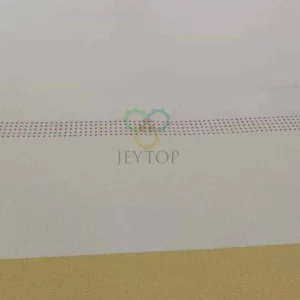

- Woven Structure: Made of high-strength multiple layer fabrics, offering stable structure and smooth operation.

- Common Edge Design: Standard edge treatment suitable for medium- and low-speed corrugator lines.

- Heat Resistance: Withstands working temperatures up to 200℃, ideal for hot drying sections.

- Good Air Permeability: Supports effective vacuum suction and improves board formation quality.

- Custom Length: Length can be tailored according to customer requirements.

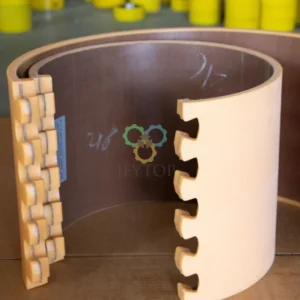

- Clipper Splice: Uses metal clipper at both belt ends, suitable for wide-format corrugator belts.

Technical Parameter of the corrugated belts common edge:

| Parameter | Value |

| Thickness | 8 – 9 mm |

| Width | 1400 – 3200 mm |

| Length | Customized as per customer need |

| Weight | Approx. 7.5 kg/m² |

| Temperature Resistance | ≤200℃ |

| Edge Type | Common Edge |

| Splice Type | Clipper |

| Speed Range | ≤150 m/min |