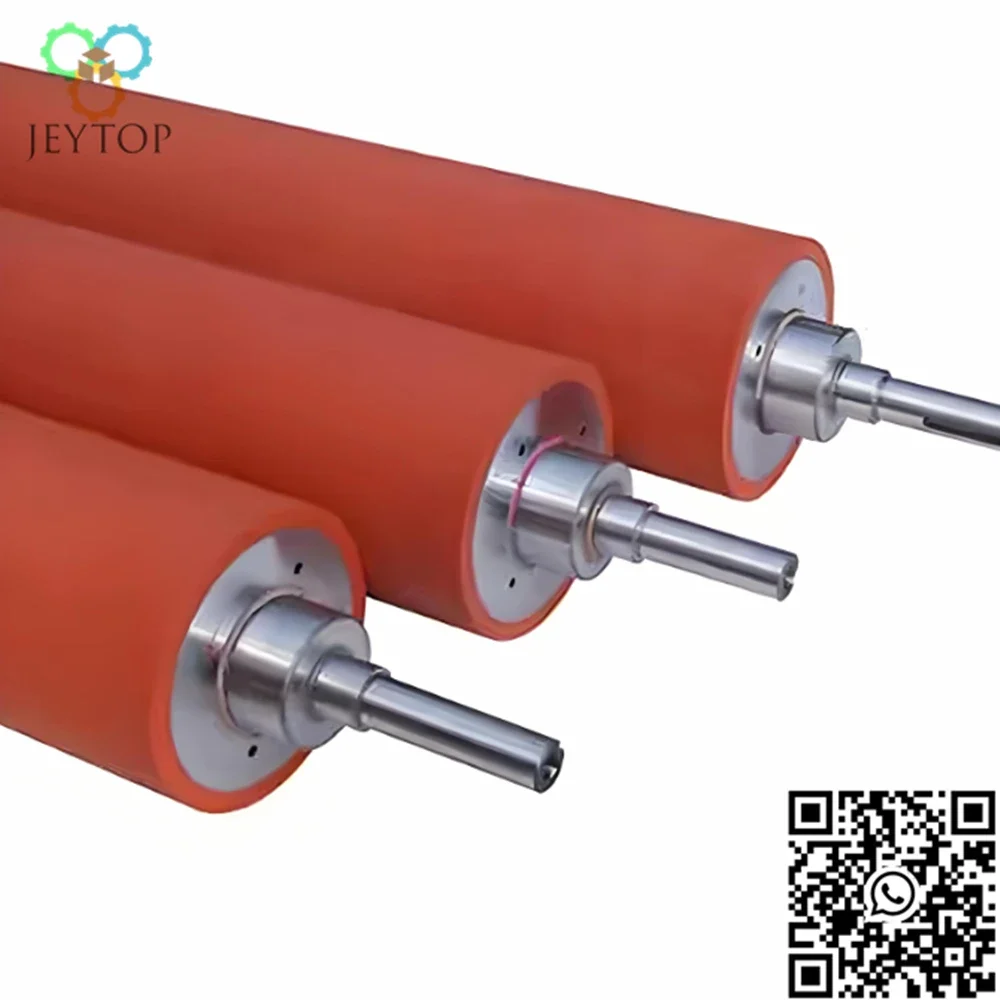

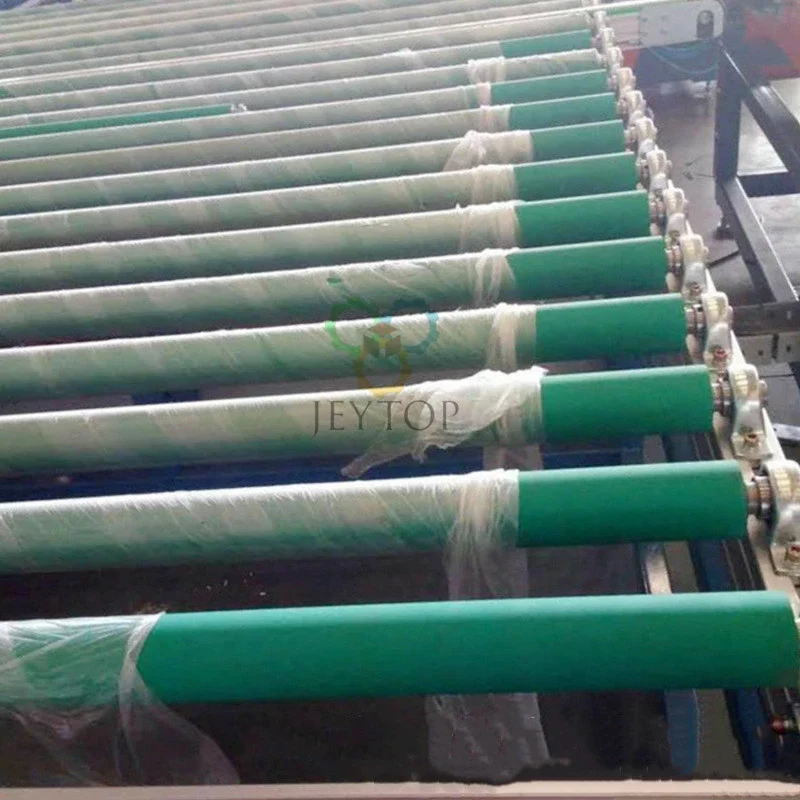

The rubber roller is an essential component widely used in printing, packaging, laminating, and various industrial applications. It consists of a high-quality steel shaft covered with rubber or elastomer materials such as NBR, EPDM, or PU. With excellent elasticity, wear resistance, and chemical stability, rubber rollers ensure smooth and consistent performance under different working conditions.

Characteristics of rubber roller:

- High Elasticity & Resilience – Ensures stable pressure and uniform contact during operation.

- Wear Resistance – Long service life even under continuous high-speed use.

- Chemical Resistance – Suitable for inks, adhesives, solvents, and coatings.

- Smooth Surface Finish – Provides excellent print quality and coating uniformity.

- Custom Options – Rubber hardness (Shore A), roller diameter, length, and surface treatments available.

Applications

- Printing Industry: Offset printing, flexographic printing, gravure printing.

- Packaging & Corrugated Industry: Used in slotting, cutting, and laminating machines.

- Laminating & Coating: Adhesive coating, varnishing, film laminating.

- Textile & Paper Industry: Calendering, embossing, and paper finishing.

- General Industrial Use: Conveying, squeezing, and material processing.

Technical Parameters (customizable)

- Base Material: Steel or stainless steel shaft.

- Covering Material: NBR, EPDM, Silicone, PU, or natural rubber.

- Hardness Range: 20–100 Shore A.

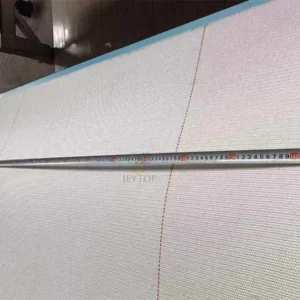

- Roller Diameter: 50–500 mm (custom sizes available).

- Roller Length: Up to 4000 mm (depending on application).

- Surface Finish: Smooth, grooved, or customized patterns.

- Temperature Resistance: -20°C to +180°C (depending on rubber type).

FAQ – Rubber Roller for Printing & Industrial Use

Q1: What is the function of a rubber roller in printing?

It transfers ink, coating, or pressure evenly during printing or laminating, ensuring stable color, smooth surfaces, and consistent quality.

Q2: What materials are used for the roller covering?

We use different elastomers such as NBR, EPDM, silicone, PU, or natural rubber, selected based on ink type, chemical resistance, and temperature requirements.

Q3: Can the rollers be customized?

Yes. Customers can specify hardness (Shore A), roller diameter, length, and surface finish. Grooved or special surface designs are also available for unique applications.

Q4: How should I maintain the roller?

Avoid exposure to strong solvents and high temperatures beyond its rating. Regular cleaning and correct storage can extend the roller’s lifespan.

Q5: Which industries commonly use this product?

They are widely applied in printing machines, corrugated packaging equipment, laminating systems, textile processing, and paper finishing.

Q6: What is the typical service life?

The lifetime depends on application, operating speed, and maintenance practices. With proper care, our rollers can provide long and stable performance.