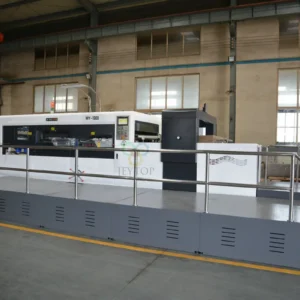

Characteristics of the platform die cutting machine:

1. This platform die-cutting machine is a versatile device that combines multiple die-cutting processes, including trimming, corner cutting, punching, slotting, and creasing, into a single die-cutting process. It delivers consistent die-cutting quality, precise dimensions, and a burr-free, smooth, and neat finish. It is also safe and easy to operate. It can even produce multiple small cartons at once, provided a mold is prepared.

2. It utilizes a two-way, two-person operation system. After entering values, the die is automatically transferred at a set time, or manually activated for automatic transfer. It is safe and convenient to operate.

3. The machine can process standard boxes, custom-shaped boxes, express boxes, airplane boxes, and products such as pearl cotton, cardboard, and hollow board.

4. The top plate is constructed of national standard 3.0mm steel plate. The main die-cutting shaft is made of high-quality drill rod with an 18.8mm wall thickness and an 8mm thick backing plate. The machine frame is constructed of double-layer 100mm national standard channel steel, AAA sealed bearings, and high-quality die-cut rubber shafts.

5. High-frequency ignition gears, Chint electrical components, and wall panels are constructed of high-quality steel plate. Screws throughout the machine are all made of high-quality ignition steel. All other components are high-quality standard parts.

Technical Parameter Of the platform die cutting machine:

| Model | Work speed | Electric power | Exterior size(mm) | The weight (kg) |

| MQJ-1200 | 0-15 pieces of paper | 2.2KW | 3000×1500×1250mm | 1000 |

| MQJ-1400 | 0-15 pieces of paper | 2.2KW | 4500×1700×1250mm | 1200 |

| MQJ-1600 | 0-15 pieces of paper | 2.2KW | 4500×1900×1250mm | 1500 |

| MQJ-1800 | 0-15 pieces of paper | 2.2KW | 5000×2100×1250mm | 1800 |