Main structure of Paper edge protection machine:

- Flanging Part of Paper Feeding

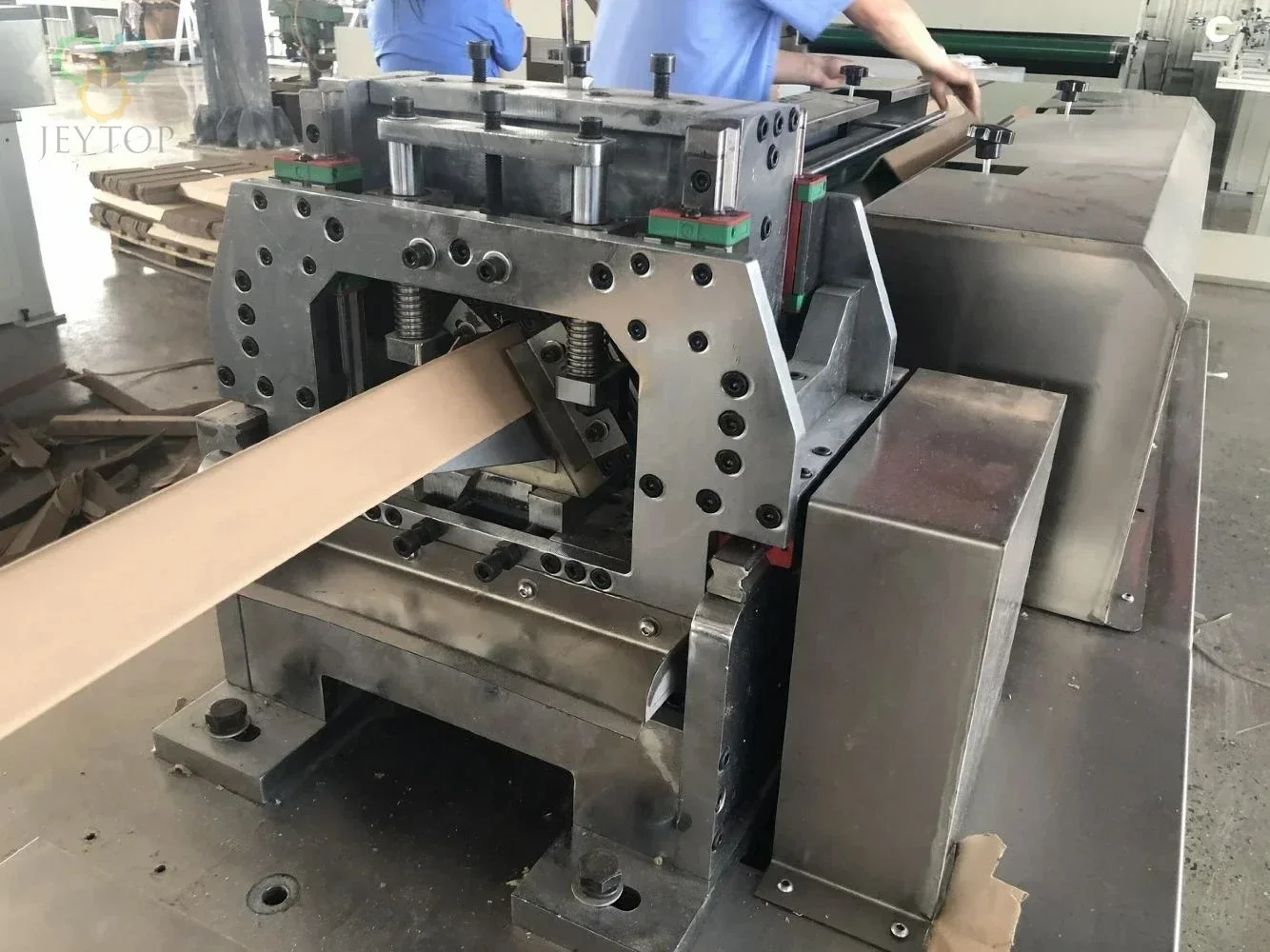

- Angle protection moulding part

- Electrical Control Part

- Cut-off part of guard angle

Characteristics of the Paper Edge Protector Machine:

- The corner protector main machine is equipped with 8 sets of V-shaped forming pressure wheels and 6 sets of flat pressure wheels, which rotate coaxially. The upper pressure wheels are adjusted pneumatically.

- It adopts frequency converters, servo motors, touch screens, and PLC human-machine interfaces, featuring simple operation and easy learning.

- The production operation is fully digitalized. Production specifications can be input into the touch screen in batches, with real-time monitoring of production quantities. The machine will automatically stop after completion.

- It has automatic alarm and fault prompt functions, facilitating maintenance.

- An edge punching and indentation device can be installed on the corner protector production line, which can punch corners with a side width of 30-80mm. Common types include 90° punches, 90° buckle punches, and 5-90° circumferential punches.

- It uses a thickened and reinforced square tube profile frame, international standard forming wheels with quenching treatment, a 10mm thick machine table panel, an integrated punching table and material throwing table process. All important components are chrome-plated, and the latest servo flying shear table ensures stable operation, high cutting accuracy, and long service life.

Technical parameter of the paper edge protector machine/angle board machine:

| Parameter/Model | HJY-100 |

| Angle board size | Width 25-100mm for V-Shaped cardboard; 25-180mm for flat cardboard; |

| Angle board thickness | 2~8mm |

| Working speed | 60m/min |

| Cutting Type | Servo motor control and cut off |

| No. of loading reels | 12 layers(can be customized) |

| Control type | HMI input, PLC control |

| Machine power | 5.5/7.5KW |

| Overall Size | 28*2 meter |

Use of the paper edge protection machine:

- The edge protection of pallet packaging can effectively pack the goods into a whole; increase the stacking strength and relieve the impact force.

- Protection of furniture and decoration, improving transportation and construction safety.

- Edge protection of various plates to prevent damage to goods caused by bumps.

- Enhance the strength and stacking capacity of ordinary cartons.

- Surface and edge protection of other products.