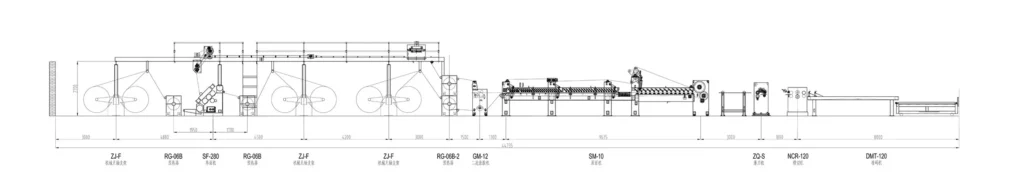

Layout of 3 ply corrugated board production line

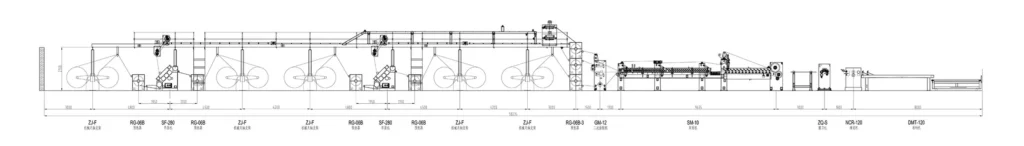

Layout of 5 ply corrugated paperboard production line

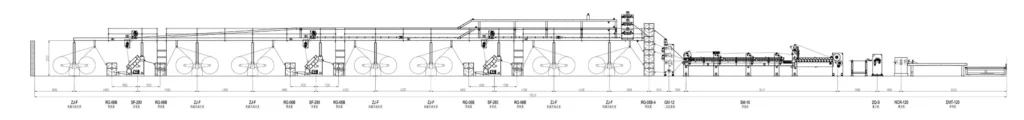

Layout of 7 ply corrugated cardboard production line

The Automatic 3/5/7 Ply Corrugated Cardboard Production Line is a fully integrated solution for large-scale corrugated packaging plants. It is designed for continuous, high-speed, and high-quality production of corrugated board, tailored to customer requirements for 3 ply, 5 ply, or 7 ply lines. With advanced automation and precision engineering, it ensures stable performance, energy efficiency, and long service life, making it an ideal choice for modern corrugated carton manufacturers.

Characteristics of 3/5/7 ply corrugated cardboard production line:

Advanced Automation

Centralized PLC + HMI control system enables real-time monitoring, production management, and easy adjustment, reducing labor intensity.Complete System Integration

Includes shaftless mill roll stand, single facer, overhead bridge, double facer, preheaters, gluing unit, slitter scorer, NC cutter, stacker, heating system, air compressor, and starch glue preparation unit.High Productivity & Accuracy

Maximum production speed up to 300m/min, with crosscutting precision of ±1mm, ensuring efficient mass production with consistent quality.Durable & Reliable

Critical components (gearbox, bearings, motors, PLC, etc.) are manufactured to international standards, ensuring stable operation and extended service life.Energy-Efficient & Easy Maintenance

Optimized design reduces energy consumption while allowing easy access for inspection, cleaning, and maintenance.

Technical parameter:

Effective Width: 1400mm – 2800mm

Production Speed: 70m/min – 300m/min

Flute Types: A, B, C, E, F

Layer Options: 3 ply / 5 ply / 7 ply (customized line according to requirement)

Cutting Accuracy: ±1mm

Power Supply: Customized according to customer’s local standards

Control System: Centralized PLC + HMI

Applications:

Corrugated Carton Manufacturing Plants

Packaging & Printing Enterprises

Food & Beverage Packaging Industry

Consumer Goods & Garment Packaging

Logistics & E-commerce Packaging