Anilox Roller is a key component in flexographic printing and coating processes. It is designed to deliver a precise and consistent amount of ink or coating to the printing plate, ensuring high-quality printing results.

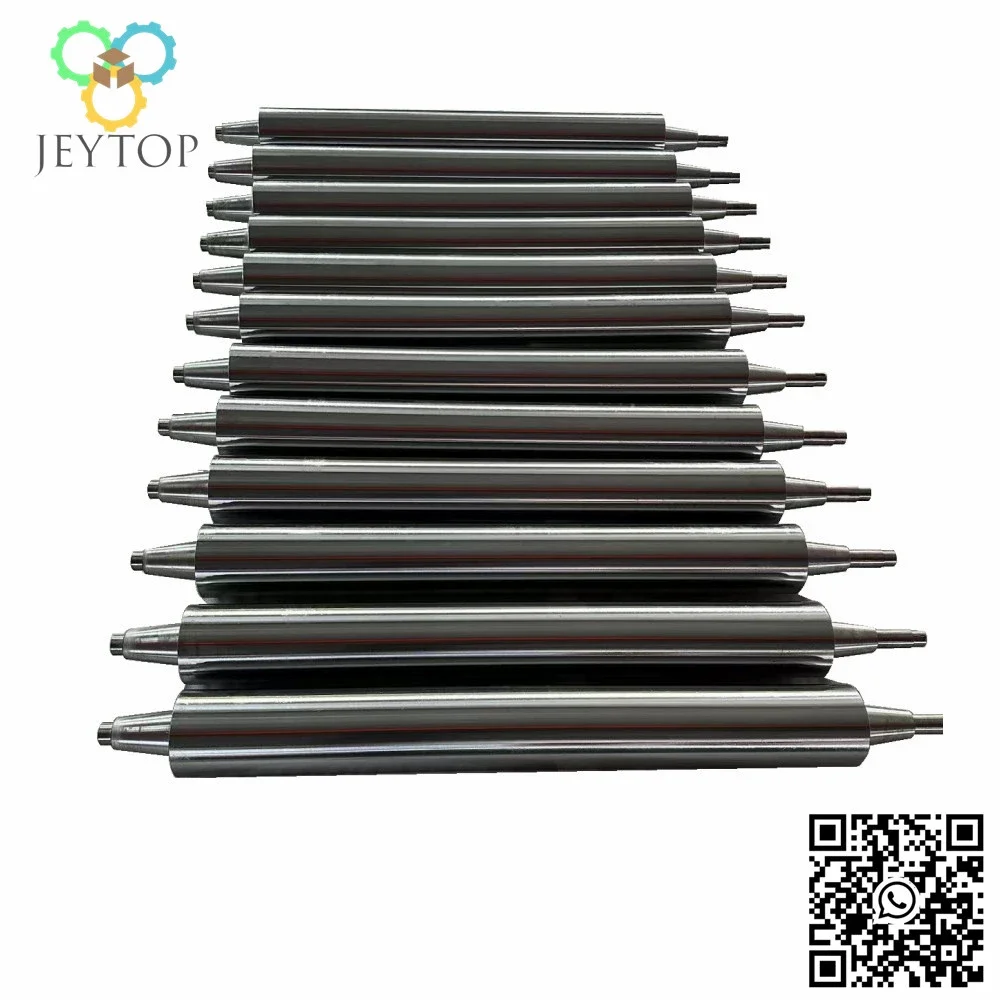

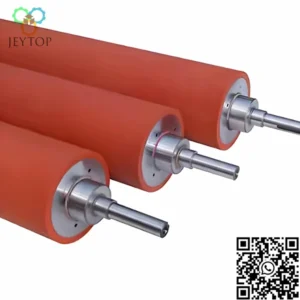

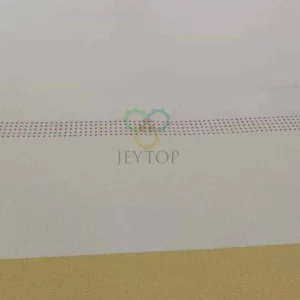

Our anilox rollers are manufactured with a steel or aluminum base and coated with ceramic material, then laser-engraved with micro cells. These cells control the ink volume and distribution, making the printing process more accurate, stable, and efficient.

Characteristics of the anilox roller:

- Material: Steel or aluminum base with ceramic coating

- Cell technology: Laser-engraved micro cells for uniform ink transfer

- Durability: High hardness, wear resistance, and corrosion resistance

- Customization: Cell volume (BCM), line screen (LPI), and surface coating options available

Applications:

- Flexographic printing for corrugated cartons, labels, flexible packaging, and paperboard

- Coating applications for adhesives, varnishes, primers, and silicone coatings

- Consistent ink transfer in both high-speed and fine-detail printing

Advantages:

- Precise ink metering for sharper and cleaner printing

- Improved color stability and printing uniformity

- Reduced ink waste and production costs

- Extended roller life with proper cleaning and maintenance

Maintenance & Cleaning:

To keep the anilox roller in top condition, it is essential to maintain clean cells. Regular cleaning methods include:

- Ultrasonic cleaning

- Chemical cleaning

- Laser cleaning

Proper maintenance ensures reliable ink transfer and extends the roller’s service life.

Technical Parameter:

| Screen count range | 80-2000 LPI |

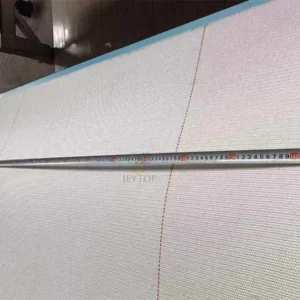

| Maximum Effective Length | 3800mm 4250mm ( with axis) |

| Mini. Effective Length | 260mm |

| Diameter range | 30-500 mm |

| Screen angle | 1-89 degree |

| Cell shape | Hexagon, quadrangle and line, etc. and the many more cell shapes may meet your requirement |

| Guarantee Time | 1 Year |

| Delivery Time | 15~20 Days |

| Payment Term | 100% T/T , Western Union, Paypal, Credit card |

Remarks:Can be customized according to customer requirements or drawings

FAQ – Anilox Roller for Flexo Printing

Q1: What is an anilox roll used for?

An anilox is used in flexo printing and coating processes to deliver a precise and consistent amount of ink or coating to the printing plate. It ensures stable color, high print quality, and reduced ink waste.

Q2: What materials are your anilox rolls made of?

Our anilox rollers are made with a steel or aluminum base, coated with high-quality ceramic, and laser-engraved with micro cells for accurate ink transfer and long service life.

Q3: Can I customize the anilox roller specifications?

Yes, we offer full customization. You can choose the cell volume (BCM), line screen (LPI), roller diameter, length, and surface coating to match your production requirements.

Q4: How do I clean and maintain an anilox roller?

To keep the cells clean and ensure stable ink transfer, regular cleaning is recommended. Common methods include ultrasonic cleaning, chemical cleaning, and laser cleaning. Proper maintenance extends roller life and improves printing quality.

Q5: What industries use anilox rollers?

Anilox rollers are widely used in corrugated carton printing, labels, flexible packaging, paperboard printing, and coating applications such as adhesives, varnishes, and silicone coatings.

Q6: How long does an anilox roll last?

With proper cleaning and maintenance, ceramic anilox rollers can last for many years. Their durability depends on printing conditions, cleaning frequency, and handling practices.