This article systematically sorts out various basic information about preheaters in corrugated board production lines, covering core industry knowledge from equipment definition, structural composition, and working principles to classification, selection, maintenance, and troubleshooting. It can be said that this is a practical reference for corrugated preheaters. Whether you are a novice just starting to use the equipment or a practitioner needing to consolidate your foundation, reading this article will provide you with clear and comprehensive information about corrugated preheater basics.

What is a Corrugated Preheater?

In a corrugated board production line, the preheater is an indispensable key equipment, mainly responsible for heating and conditioning the base paper (including face paper, back paper, core paper, etc.) used to produce corrugated boards.

In production, the moisture and temperature of the paper directly affect product quality: excessive moisture can lead to poor corrugation formation and weak adhesion; improper temperature may increase paper brittleness and affect strength. The corrugated preheater adjusts these parameters through reasonable heating, laying the foundation for high-quality corrugated board production.

What Components Make Up a Corrugated Preheater?

A corrugated preheater mainly consists of the following key components:

- Heating roller: As the core heating area, it is similar to the base of an electric iron. Paper absorbs heat through contact with it. It is usually made of high-quality steel with a smooth surface (e.g., roughness below Ra0.8μm) to ensure uniform heating of the paper. If the surface roughness is too high, it may cause uneven local heating of the paper, affecting subsequent corrugation formation.

- Pressure roller: Functioning like a press, it applies pressure to the paper to make it closely adhere to the heating roller, ensuring sufficient heat absorption. The pressure can be adjusted according to paper thickness and material. For example, for 120g/m² face paper, a pressure setting of 0.3-0.5MPa is appropriate — pressure below 0.3MPa may result in insufficient heating due to poor adhesion, while pressure above 0.5MPa may crush the edges of thin paper.

- Transmission device: Serving as the power source, it consists of motors, gears, chains, etc., driving the heating roller and pressure roller to rotate and ensuring smooth paper passage. Loose transmission components may cause unstable paper conveying.

- Temperature control system: The key to controlling the temperature of the heating roller, usually using thermocouples or PT100 thermal resistors as sensors. Some models have PID adjustment functions, with a temperature control accuracy of ±1℃. It can set the appropriate temperature according to paper type and production requirements; once out of control, it may cause sudden changes in paper moisture, leading to problems such as corrugation collapse.

- Frame: Acting as a supporting skeleton, it fixes all components, ensuring the equipment structure is stable and operates smoothly during production.

What Are the Classifications of Corrugated Preheaters?

Corrugated preheaters on the market are mainly classified as follows:

By Heating Method:

- Steam-heated corrugated preheater: Uses steam as the heat source to heat paper through heat exchange. It heats evenly, with temperature fluctuations controllable within ±2℃, making it suitable for scenarios requiring high heating quality, such as stably adjusting paper conditions when producing high-strength multi-layer boards.

- Electrically heated corrugated preheater: Uses electricity as the heat source, generating heat through electric heating tubes. It is easy to install and use, with fast heating speed (only 5-8 minutes to rise from room temperature to 100℃), but has higher operating costs, making it suitable for small production lines or situations requiring rapid heating.

By Structural Form:

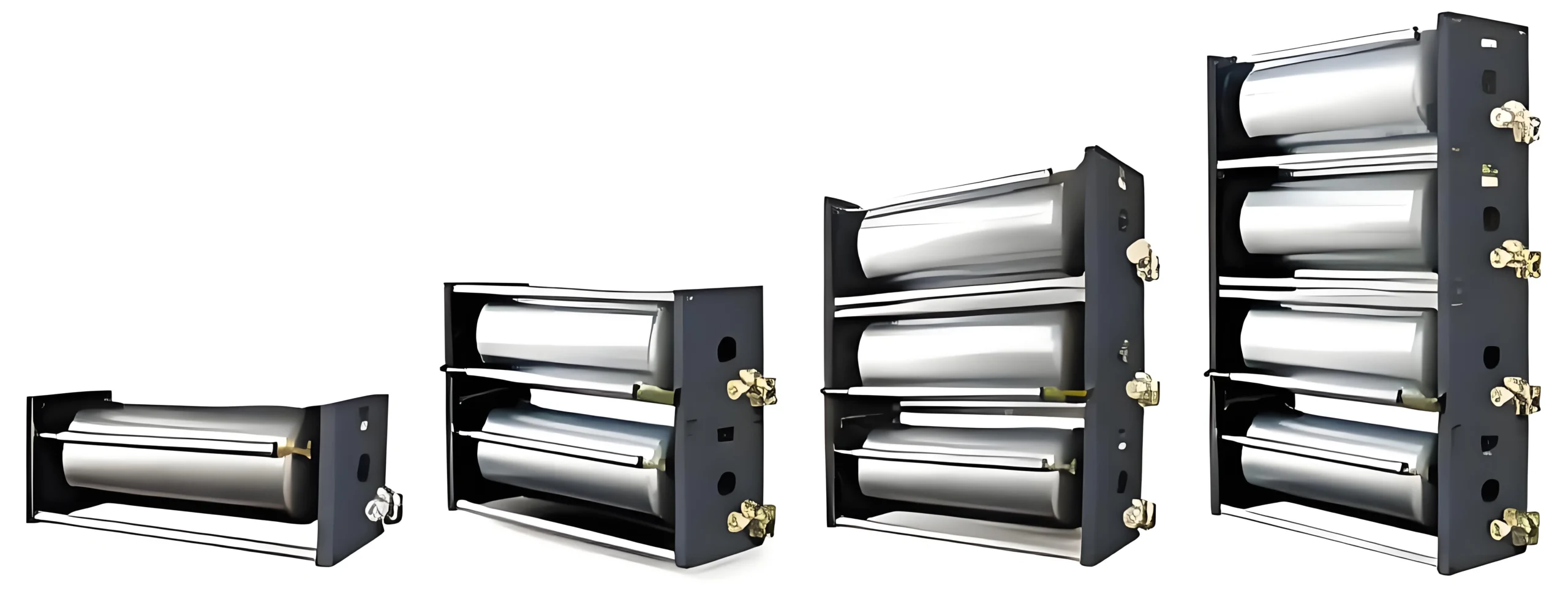

- Single-roller corrugated preheater: Has only one heating roller, with a simple structure and small size. It is suitable for production with low preheating requirements, such as small workshop-style production lines or processing of single-specification boards.

- Double-roller corrugated preheater: Composed of two heating rollers, with paper passing between them. It has better heating efficiency and conditioning effect than single-roller preheaters, enabling more sufficient adjustment of moisture and temperature, and is suitable for medium-sized production lines and multi-specification board production.

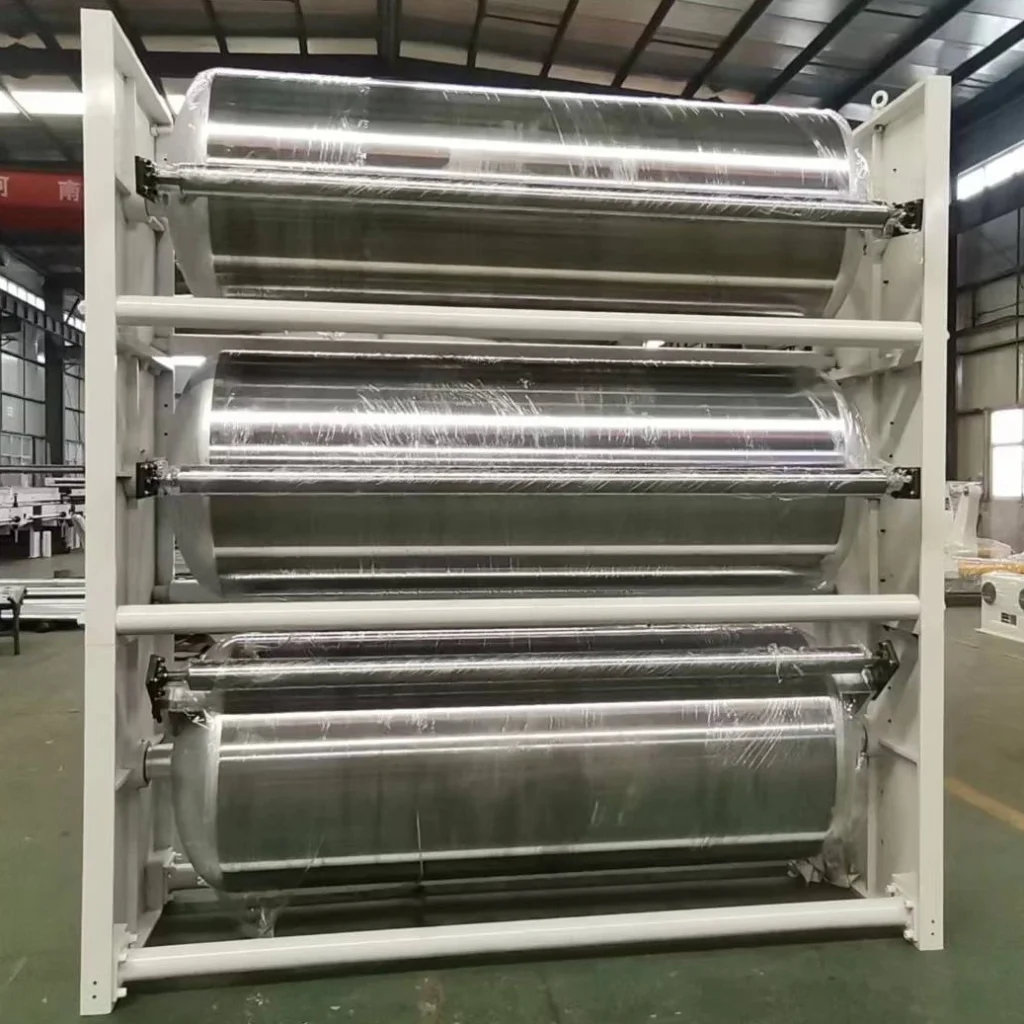

- Three-roller and multi-roller corrugated preheaters: Contain three or more heating rollers. Paper is continuously heated by multiple sets of rollers, enabling stepwise temperature adjustment and in-depth conditioning. They can precisely control moisture gradients and reduce sudden moisture changes, making them suitable for large high-speed production lines, thick board production, or high-demand scenarios (such as high-strength, multi-layer composite boards).

How Does a Corrugated Preheater Work?

The working process of a corrugated preheater is as follows: The paper to be processed enters from the paper inlet and is conveyed between the heating roller and pressure roller by the transmission device.

At this time, the pressure roller applies appropriate pressure to make the paper closely adhere to the heating roller; the heating roller generates heat through internal steam pipes or electric heating tubes, which is transferred to the paper for heating.

During heating, the temperature control system monitors and adjusts the temperature in real-time: the temperature for face paper is usually set to 60-80℃, while for core paper, which requires more moisture adjustment, it is set to 80-100℃.

After heating, the moisture content of the paper drops from about 12% to 8-10%, and the temperature rises. Once it reaches the state required for subsequent processing, it is sent out from the paper outlet. In multi-roller models, the paper is gradually regulated by multiple sets of rollers — for example, in a three-roller preheater, the first roller (50-60℃) removes surface moisture, the second roller (70-80℃) adjusts internal moisture, and the third roller (90-100℃) stabilizes the state. The specific temperature is adjusted according to the number of board layers (three, five, seven layers).

Why Use a Corrugated Preheater?

The main reasons for using a corrugated preheater are as follows:

- Improve corrugated board quality: After preheating, the paper has uniform moisture and enhanced flexibility, enabling it to better adapt to the shape of corrugating rollers during subsequent corrugation formation, reducing cracking and wrinkling, and making the corrugation more regular and stronger — the edge crush strength of corrugated boards can be increased by 10-15%.

- Improve production efficiency: Appropriate temperature and moisture allow the paper to better bond with glue in the bonding process, shortening the bonding time from 3-5 seconds to 1-2 seconds and accelerating the production process.

- Reduce raw material waste: Without a preheater, paper is prone to breakage, with a scrap rate as high as 5-8%; with a preheater, the scrap rate can be reduced to below 2%, saving costs.

How to Select a Corrugated Preheater?

When selecting a corrugated preheater, consider the following aspects:

- Production needs: For large high-speed production lines or production of thick boards and high-strength boards, three-roller/multi-roller, steam-heated models are optional; for medium-sized production lines, double-roller models are suitable; for small simple production lines, single-roller electric-heated models are appropriate.

- Heating effect: Pay attention to heating uniformity and temperature control accuracy. For example, equipment with a heating roller surface roughness below Ra0.8μm ensures more uniform paper heating, reducing quality problems caused by uneven heating.

- Equipment quality: Check the material and manufacturing process. Rollers made of high-quality steel and precision transmission devices can extend service life — high-quality heating rollers can have a service life of over 50,000 hours. The heating rollers of JEYTOP preheaters are made of 45# high-quality carbon steel and undergo quenching and tempering treatment to ensure durability.

- Energy consumption cost: Steam-heated models have high initial investment but low long-term operating costs (energy consumption per hour is 30-40% lower than that of electric-heated models); electric-heated models have low initial investment but higher electricity fees. The choice should be based on budget and production conditions.

- After-sales service: Choose manufacturers with good after-sales service. JEYTOP has a professional team and promises to respond to fault reports within 24 hours. For example, after a customer reported a equipment fault, the team arrived for maintenance within 4 hours, reducing downtime losses.

How to Maintain a Corrugated Preheater?

Proper maintenance can extend the service life of the corrugated preheater and ensure smooth production.

- Daily maintenance: After production each day, clean dust and paper scraps from the equipment surface; check whether the surfaces of the heating roller and pressure roller have scratches — observe residual marks on the paper under natural light, and promptly handle regular indentations if found; for multi-roller models, check the fit and pressure uniformity of each roller one by one.

- Regular inspection: Every 100-200 hours of operation, check whether the chains and gears of the transmission device are loose or worn, and add special gear oil in a timely manner; check the temperature control system, and calibrate it when the temperature display error exceeds ±3℃; for multi-roller models, focus on checking roller synchronization (speed difference not exceeding ±1rpm), which can be simply judged by observing whether the paper conveying is offset.

- Regular cleaning: Clean scale or impurities inside the heating roller every 3 months to prevent affecting heating; for steam-heated models, check the tightness of steam pipes; for multi-roller models, clean paper scraps in the gaps between rollers to avoid hindering paper conveying.

What Are Common Faults of Corrugated Preheaters and Their Solutions?

- Uneven heating: May be caused by dirt on the heating roller surface, improper temperature control, or abnormal temperature of a certain group of rollers in multi-roller models. Solutions: Clean the heating roller with food-grade stainless steel cleaner; check the temperature control system and calibrate the sensor (ensure the error is ≤±1℃); for multi-roller models, separately detect and repair the heating status of each group of rollers.

- Paper deviation: May be caused by loose transmission components, uneven pressure of the pressure roller, or deviation in roller parallelism in multi-roller models. Solutions: Tighten transmission components and adjust the pressure of the pressure roller; for multi-roller models, calibrate roller parallelism with a laser level (ensure the deviation is ≤0.1mm/m), and daily simply judge parallelism by observing whether the paper edge is aligned with the conveying track.

- Temperature out of control: May be caused by damage to the relay or heating element of the temperature control system; in multi-roller models, a certain group of heating modules may be faulty. Solutions: Check and replace damaged components; for multi-roller models, check each heating module one by one and replace faulty units.

What Are the Advantages of JEYTOP Corrugated Preheaters?

JEYTOP Corrugated Carton Machinery is rooted in China’s core industrial cluster of corrugated carton machinery. Relying on the entire industrial chain resources, it achieves localized efficient collaboration, with a production cycle 15%-20% shorter than the industry average and higher cost performance. For example, through JEYTOP’s industrial chain collaboration, the equipment delivery time of a large production line was shortened from the industry average of 45 days to 36 days.

JEYTOP corrugated preheaters have multiple series of models covering various scenarios: after a large carton factory for home appliance packaging used the three-roller model, the edge crush strength of corrugated boards increased by 15%, the scrap rate dropped from 6% to 1.8%, and the production speed reached 250 meters per minute; a small and medium-sized customer using the electric-heated model saves about 800 yuan in electricity fees per month compared to similar products.

All models operate stably. Some models have functions such as intelligent temperature control (automatically detecting paper moisture and increasing the temperature of the third roller by 5℃ when the core paper moisture is too high) and multi-stage heating; they can be equipped with precision sensing components and remote diagnosis modules (reducing fault response time to 2 hours). Customization is also available, such as anti-condensation preheaters for customers in high-humidity areas to solve paper moisture regain. After a customer in southern China used it, the scrap rate caused by moisture regain dropped by 3%.

JEYTOP has been deeply involved in the industry for 15 years, is a national high-tech enterprise, provides solutions for packaging enterprises worldwide (covering home appliances and food fields), serves thousands of carton factories, and its equipment has passed CE and ISO9001 certifications, providing full-process services from selection to training.

For custom corrugated preheater solutions for your production line, please contact JEYTOP, and our professional team will provide support.

Connect with Us

🌐 Visit our website: [jeytop.com]

🔗 Follow on LinkedIn: [Yong Li—Jeytop Carton Machinery]

📧 Email: [jeytopmachinery@163.com]

📱 WhatsApp:[https://wa.me/8615230792110]