Welcome to read this article, which is a comprehensive guide on the auto paper splicer for corrugated cardboard production lines. If you are seeking any information about the auto splicer for corrugated line, you can find it all in this article. So please continue reading to learn more.

1. What Are the Disadvantages of Traditional Paper Splicing Methods in Corrugated Production?

In corrugated board manufacturing, traditional manual splicing requires operators to monitor the remaining volume of paper rolls closely, leading to critical inefficiencies. Each splicing takes 3-5 minutes with only a 70%-80% success rate, often causing paper breaks due to human error. This results in a 1%-2% waste rate—for a medium-sized line with 10 daily roll changes, that’s 50-100m of base paper wasted daily, translating to $10,000-$20,000 annual losses. Frequent shutdowns also disrupt just-in-time delivery, risking customer satisfaction.

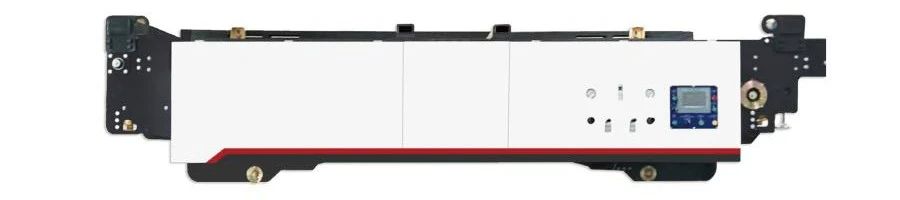

2. What Is an Auto Splicer For Corrugated Line And How Does It Work?

1) What Is an Auto Splicer?

An Auto Splicer is core equipment for corrugated line, enabling seamless roll transitions without manual intervention. Using laser sensors to detect roll diameter, it triggers automatic adhesive lamination when the old roll reaches the set minimum, ensuring continuous 350m/min+ high-speed production.

2) How Does an Auto Splicer Work?

Take the closed-loop control system: a servo motor drives the paper storage cart with ±0.5mm precision, while a magnetic powder clutch adjusts tension. When the sensor detects the roll diameter < set value, new & old rolls align in the splicing area, completed by the adhesive device. Tested success rate: 99.9% for high-speed corrugated lines.

3. What are the components of the Auto Splicer For Corrugated Line

1)Control System:

PLC & servo controller for precise logic in high-speed operations.

2)Drive Mechanism:

Asynchronous servo motor with magnetic powder clutch for tension control.

3)Detection Devices:

Laser sensors monitor roll diameter in real-time for accurate splicing.

4)HMI:

Touch screen for parameter setting, fault diagnosis, and live operation monitoring.

4. Why Corrugated Producers Choose Auto Splicer: Key Advantages

1)Efficiency Boost:

Splicing time slashed to 10-40s/operation, saving 80% vs manual—20-40min daily shutdown reduction for 350m/min high-speed lines.

2)Cost Reduction:

Waste rate <0.3%, 50% labor cost saving. JeyTop’s economical models have 30% lower annual maintenance than the industry average.

3)Versatile Compatibility:

Supports kraft paper, 1.8-2.8m width rolls, fitting corrugated lines, gray board machines, cutters, and laminators.

5. When to Invest in an Auto Splicer?

1)Large-Scale Production:

Producers with >10 daily roll changes (e.g., 5,000+ tons annual output).

2)High-Speed Requirements:

Lines operating at 350m/min or demanding 99%+ splicing success for medium-to-high-end corrugated products.

3)Labor Cost Sensitivity:

Enterprises aiming to automate splicing to reduce manpower—saves multiple operators per line.

6. How to Choose the Right Auto Splicer for Your Corrugated Line?

1)Technical Parameters Matching:

- 120m/min lines: Economical FY-Eco150 (1.8-2.5m width, domestic open-loop).

- 250m/min+ lines: Leap Series FY-Fly 300 (Taiwan/Siemens closed-loop).

- High-speed lines: Hongmeng 450 Model (350m/min, 80g/m² ultra-low basis weight optimized).

2)Control System Selection:

Open-loop for budget constraints; German/Taiwanese closed-loop (e.g., Hongmeng 450’s double-head splicing) for precision.

3)After-Sales & Maintenance:

Prioritize brands with remote modules (JeyTop offers 4-hr response + 3-year key component warranty).

7. JeyTop Carton Machinery: Your Trusted Auto Splicer Provider

With 15 years in corrugated equipment R&D, our auto splicer series includes:

- FY-Eco150: 1.8-2.5m width, 120m/min, ideal for small-to-medium lines.

- FY-Fly 300: 200-250m/min, Taiwan/Siemens servo drive, internationally verified stability.

- Hongmeng 450: Industry-leading 350m/min, remote diagnosis, optimized for 80g/m² materials.

All models feature touch screen intelligent monitoring and auto minimum diameter setting. Optional German precision components available for enhanced performance.

Enterprise endorsement reinforcement:

Certified by CE & ISO 9001, serving 3,000+ global carton factories.

One-stop services: installation, debugging, operator training—ensuring your corrugated line runs at peak efficiency.

Ready to cut waste and boost productivity? [Request a Free Quote] for our high-speed Auto Splicers tailored to your corrugated production needs.

🌐 Visit our website: [jeytop.com]

🔗 Follow on LinkedIn: [Yong Li—Jeytop Carton Machinery]

📧 Email: [jeytopmachinery@163.com]

📱 WhatsApp:[https://wa.me/8615230792110]