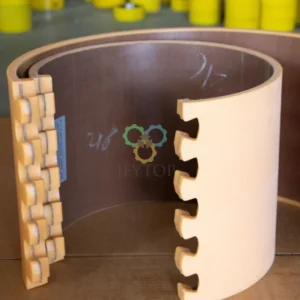

Characteristics of the Kevlar Edge Corrugator Belt:

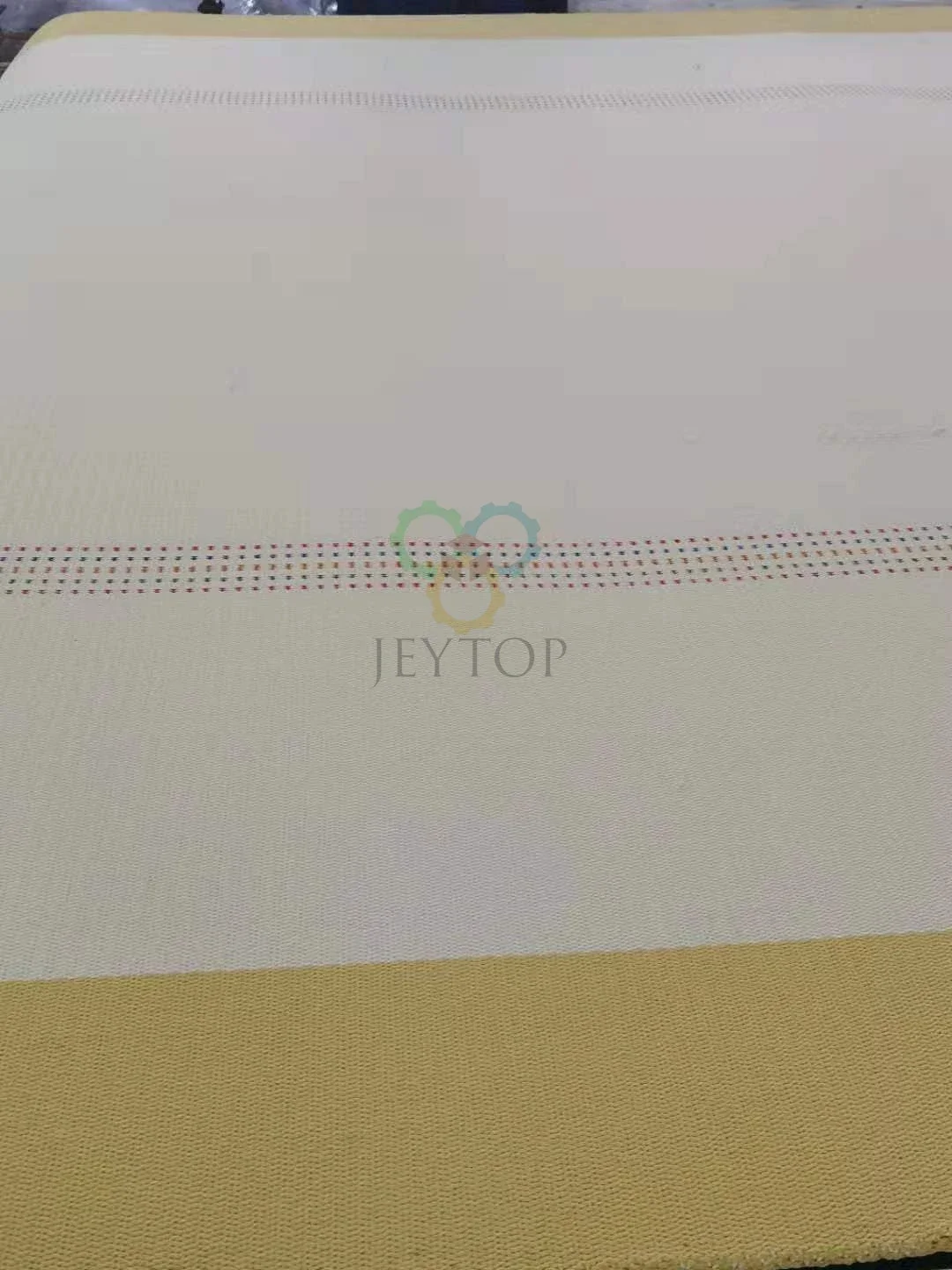

- Kevlar Reinforced Edge :Both belt edges are reinforced with Kevlar aramid fiber, providing excellent abrasion resistance and extended edge life in demanding environments.

- High Heat Resistance:The inner layer of the belt can withstand temperatures up to 350℃, making it suitable for high-temperature sections of the corrugator double facer.

- DuPont Aramid Material:The Kevlar® used is sourced from DuPont (USA), known for its consistent quality and high-performance thermal and mechanical properties.

- Stable Operation:Kevlar edge improves tracking stability, reduces edge fraying, and supports long-term use in high-speed and high-load corrugation lines.

- Air Permeable Base:Base structure maintains sufficient air permeability for vacuum suction and even board drying.

Technical Parameter Of The Kevlar Edge Corrugator Belt:

| Parameter | Value |

| Thickness | 8 – 9 mm |

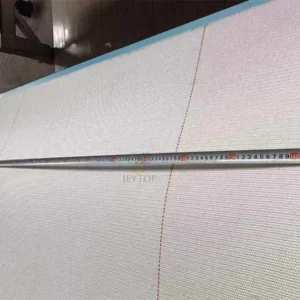

| Width | 1400 – 3200 mm |

| Length | Customized as per machine requirement |

| Weight | Approx. 7.5 – 8.5 kg/m² |

| Temperature Resistance | Inner Layer: ≤350℃ |

| Edge Type | Kevlar® Edge, 200mm width (each side) |

| Edge Material Origin | DuPont® (USA) Aramid Fiber |

| Splice Type | Clipper (metal fastener) |

| Air Permeability | 20 – 40 m³/m²·h (typical range) |

| Suitable Speed | ≤250 m/min |