Characteristics of the corrugated conveyor systems:

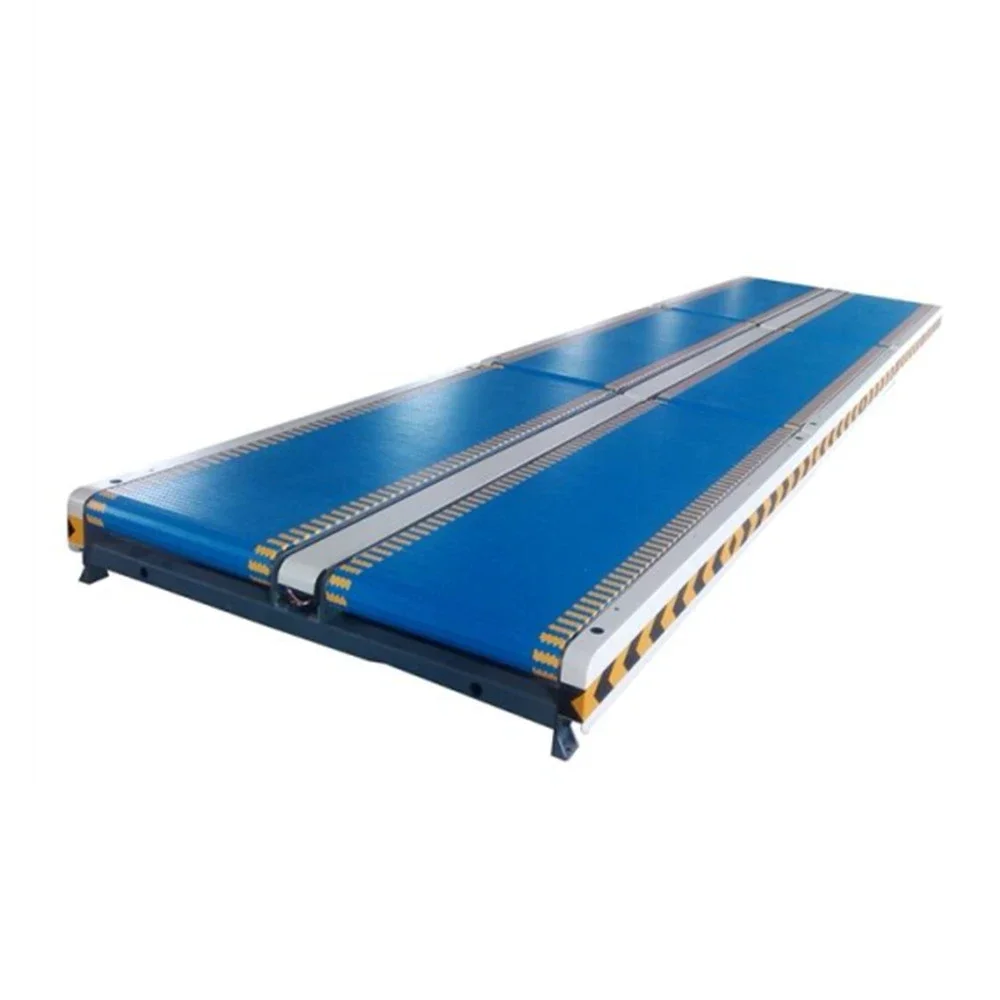

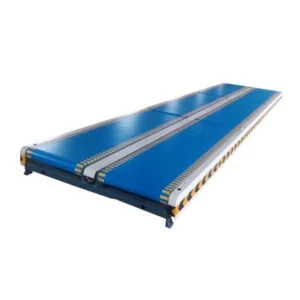

- The corrugated paper conveyor is an kind of plastic modular chain conveyor. It provides a solid traveling surface for unit loads.

- Each section of the conveyor is powered independently allowing simultaneous stack movement and load building. Gaps between adjacent section have been significantly minimized to provide greater load stability and insure transfer of even the smallest stack size.

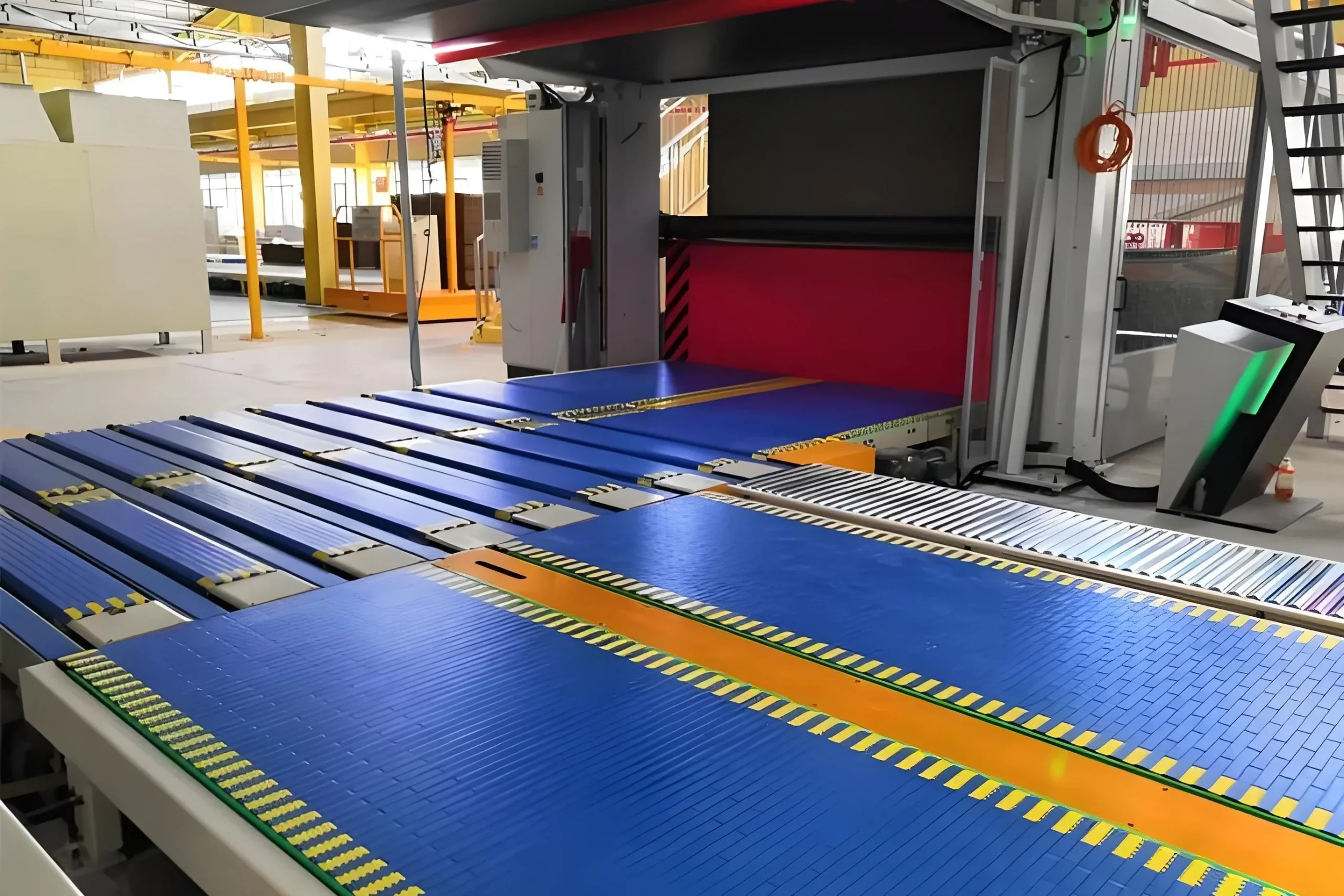

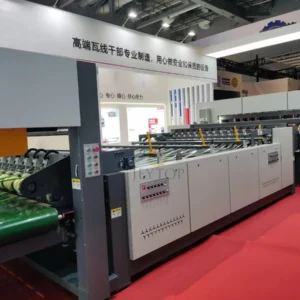

- The corrugated paper conveyor can be used for most folding carton and corrugated conveying application, Can be used with corrugated cardboard production line. It is ideally suited to corrugated outfeed and machine infeed sheet staging system. Though well suited for use in processes not utilizing pallets, its high level of durability allows it to also perform well in applications requiring finished good pallets.

- Minimum gap between chains offers smooth transfer while stack vibration is reduce to a minimum.

- Eliminate need for expensive lubricants.

- No pallets necessary. Eliminates interlocking sheets and bottom sheet damage.

- Automation degree is greatly increased while significantly reducing noise.

- Narrow loads are safely conveyed.

- Lower repair costs and downtime. Chain can be repaired without moving the conveyor.

Technical Parameter of the corrugated conveyor systems:

| No. | Parameter | Details |

| 1 | Matched Corrugator Available Dimension | 2200 mm, 2500 mm, 2800 mm etc.. |

| 2 | Conveyor Dimension | Width:2000 mm Length: 2000 mm*3 Sets= 6000 mm Min Height: 320 mm |

| 3 | Production Capacity | Around One stacks per minute |

| 4 | Structure Design | Dual Line Design |

| 5 | Total Power | 12 KW |

| 6 | With PLC Control | Schneider Inverter, SEW Motor, Schneider HMI |

| 7 | Loading | Max 250Kgs/ Square Meter |

| 8 | Additional Device | 1. Automatic Pusher-Pneumatic Power, Airtac 2. Clipper |

| 9 | Conveyor Speed | 17 Meters/Minute |

| 10 | Conveyor Modular Belt | Anti-slip Design Blue and Yellow Color |

Remarks:Can produce the corrugated conveyor systems according to your special requirement.