Reading time: ~3 minutes

Core objective:

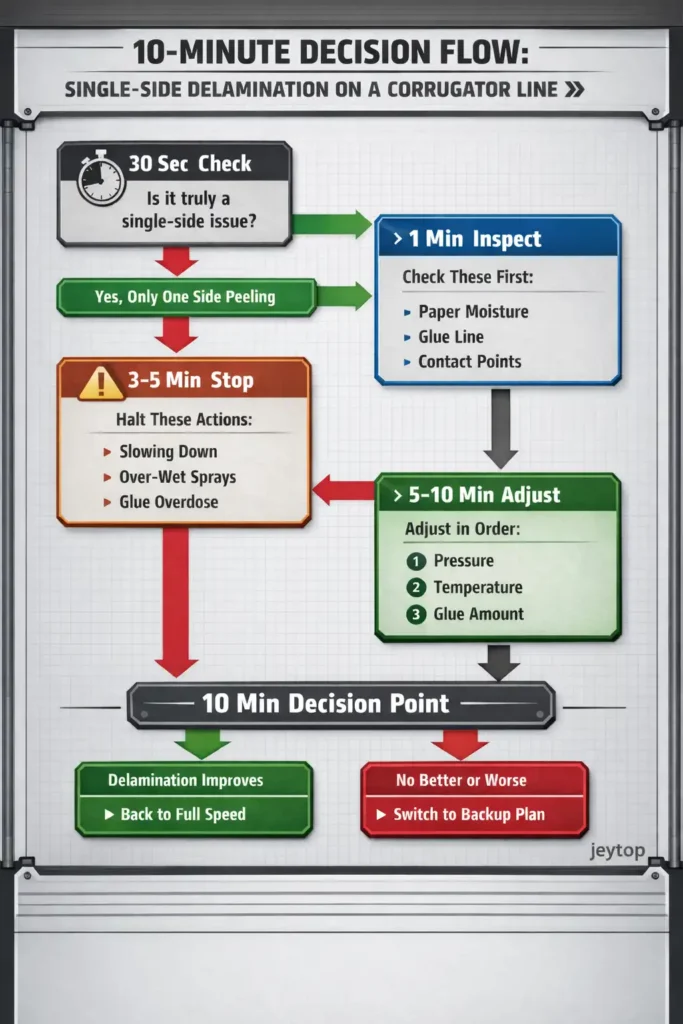

When corrugated board starts delaminating on only one side, this checklist helps you stabilize the situation within 10 minutes—preventing incorrect adjustments that can turn a local issue into a full-line failure.

Conclusion First (for those under pressure)

Single-side delamination ≠ poor glue ≠ excessive speed.

In real corrugator line operations, over 90% of single-side delamination incidents are mishandled at the very first step.

Operators instinctively slow down the line, change the adhesive formula, or increase glue application—often causing a localized issue to spread across the entire width.

The correct mindset is simple:

Treat this as local surgery, not full-scale intervention.

Follow the six steps below in order.

Step 1: 30-Second Confirmation — Is This Truly a “Single-Side” Issue?

Before touching any controls, define the boundary of the problem.

- Take a sample: Stop stacking briefly and cut a short section of freshly produced board.

- Manual check: Gently peel the liner from the fluting on the affected side and assess the bonding failure.

Key decision point:

- ✅ Proceed with this checklist: Delamination occurs consistently on the same side (operator side or drive side).

- ❌ Outside this scope: The delamination shifts sides or affects the full width. This indicates a global issue and requires a different approach.

Remember:

Stable single-side delamination (single-side bonding failure) is almost always a sign of local imbalance, not a system-wide defect.

Step 2: Minute 1 — Check Three Asymmetries

Do not adjust parameters yet. Spend one minute observing what is visibly “uneven.”

- Paper condition:

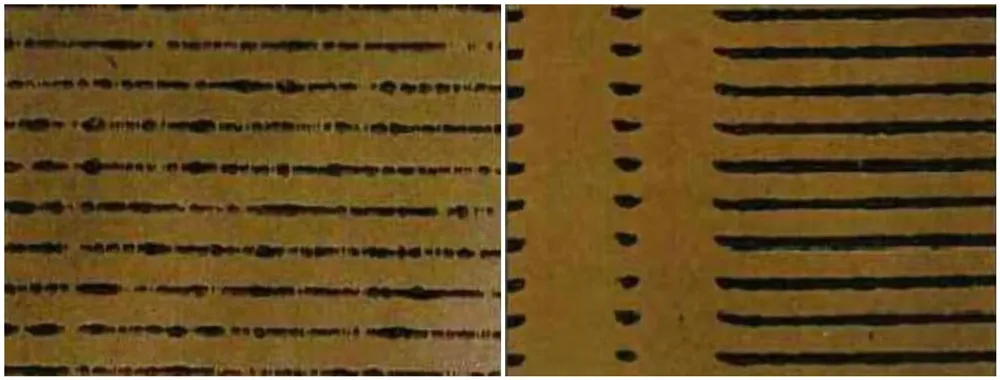

Compare liner and medium on both sides. Does the affected side feel damper, drier, colder, or more wrinkled? - Glue line appearance:

Is the glue line missing, broken, or bead-like on the affected side?

The normal side should show a thin, continuous line. - Contact points:

Inspect the corresponding preheaters and pressure rollers on the affected side.

Look for steam leakage, condensation dripping, or localized contamination.

Field reminder:

If the issue appears immediately after changing one paper roll, treat paper variability (moisture, temperature, or tension difference) as the primary suspect.

Step 3: Minutes 3–5 — Actions That Must Stop Immediately

Until clear evidence is found, the following actions will almost always worsen the situation:

- ❌ Do not immediately reduce line speed.

Speed changes disturb thermal balance and glue transfer across the entire corrugator. - ❌ Do not change adhesive formulation plant-wide.

Single-side problems are rarely caused by glue recipes. - ❌ Do not aggressively increase glue application.

More glue does not guarantee stronger bonding and often introduces drying defects. - ❌ Do not assume mechanical failure and stop the line.

Unless clear damage is visible, this is usually a misdiagnosis.

Principle:

Minimum intervention. Your goal is damage control, not blind correction.

Step 4: Minutes 5–10 — Micro-Adjustment Order

Pressure → Temperature → Glue

If Step 2 revealed a clear abnormality, proceed carefully.

Adjust one variable at a time, within ±5%, and observe results for 2–3 minutes.

Pressure (first priority):

Uneven pressure is the most common cause.

Slightly correct the pressure or parallelism on the affected side.

Temperature (second):

If touch or infrared measurement confirms lower temperature, slightly increase wrap angle or local steam input.

Glue (last):

Only after pressure and temperature are balanced should glue gap or doctor settings be adjusted on the affected side.

Counterintuitive truth — why speed comes last:

Reducing speed does not equalize side-to-side heat or tension.

In fact, it often amplifies moisture and expansion differences, making the root cause harder to isolate. Many “worsening” cases start with premature speed reduction.For a general industry overview of corrugated board bonding principles, see FEFCO’s technical resources on corrugating and adhesion.

Step 5: The 10-Minute Decision Point

At the 10-minute mark, decide calmly:

Scenario A: Delamination improves or disappears

- Action: Hold parameters steady and monitor for at least 30 minutes.

You have likely corrected the imbalance.

Scenario B: No improvement or further deterioration

- Action: Stop all adjustments and restore original settings immediately.

- Conclusion: The cause is likely upstream or mechanical—paper quality variation, single facer roll wear, or structural alignment issues.

Ask yourself one final question:

“Can I clearly explain why the problem occurred on only one side?”

If the answer is vague or based on assumption, further adjustment becomes guesswork.

Tag the affected batch, document actions taken, and escalate for deeper analysis.

Step 6: Closing — Beyond a Single Fix

This checklist is more than a troubleshooting guide:

- For operators: A time-based decision aid that reduces stress during unstable moments.

- For supervisors: A benchmark for evaluating whether on-site adjustments are rational or reactive.

- For management: An example of converting individual experience into repeatable operational knowledge.

Final reminder:

Corrugator operation is not about perfect parameters.

It is about maintaining correct thinking under pressure.

This checklist exists to support that discipline—when it matters most.

Visual Decision Flow: 10-Minute Single-Side Delamination Checklist