When low-grammage corrugated boards begin to show bonding failure, stop immediately—

before adjusting glue formulas, increasing pressure, or “trying one more setting.”

Because in low-grammage production, most losses are not caused by the problem itself, but by making the wrong decision in the very first step.

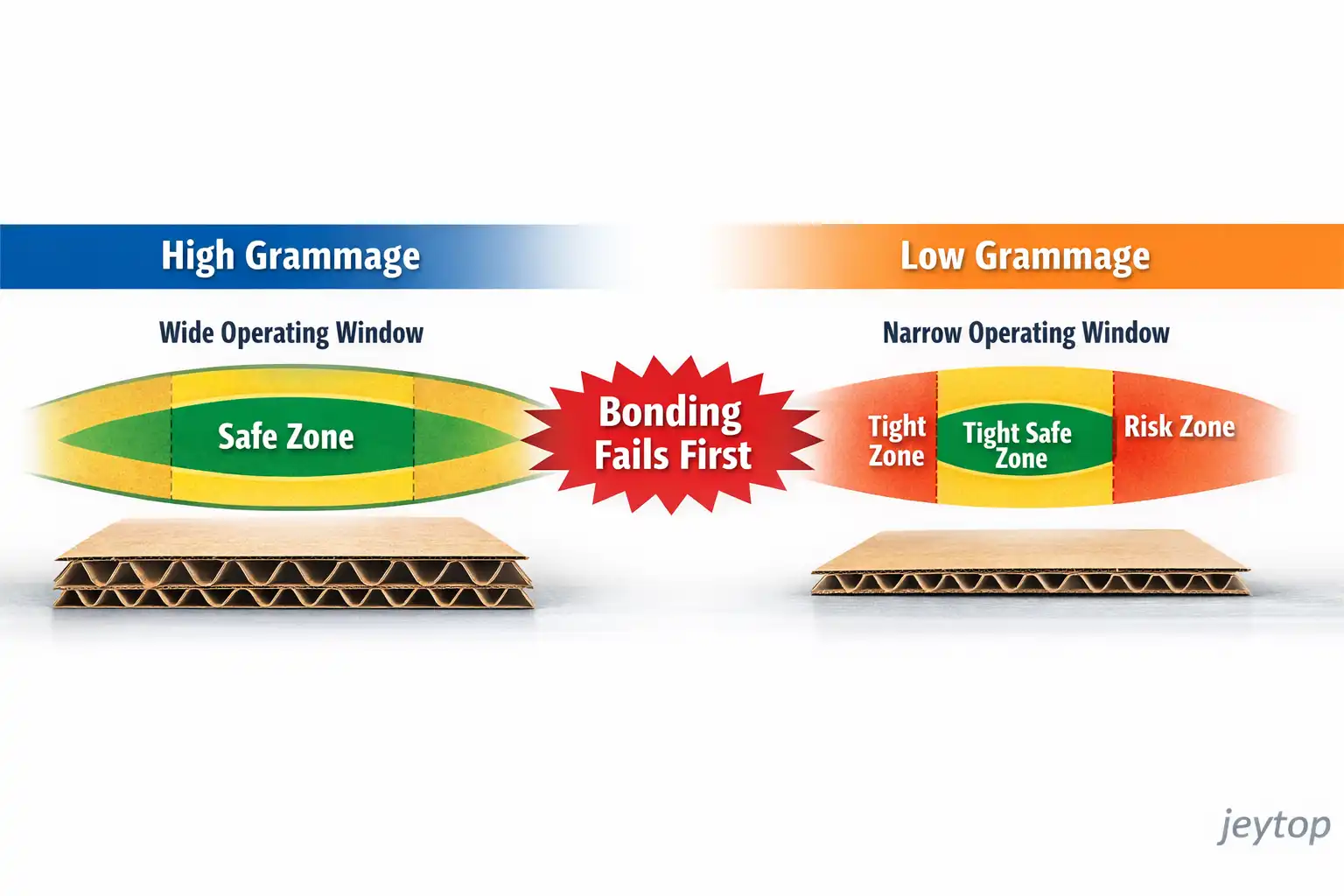

Low grammage does not mean “harder to run.”

What actually changes is this:

The system’s tolerance window collapses.

Practices that worked in the high-grammage era—

adjusting glue first, adding pressure, forcing bonding—

often turn from experience into damage-amplifying mistakes under low-grammage conditions.

This is not a parameter-tuning task.

It is a decision-sequence test.

This article focuses on one thing only:

how to determine the correct diagnostic direction when low-grammage bonding fails.

In most low-grammage cases, bonding failure is not a glue problem

This is counterintuitive—but essential.

In low-grammage production, glue rarely “suddenly fails.”

Bonding failure is usually a result signal, not the root cause.

It indicates that the entire production system has been pushed to the edge of its stable operating window.

Bonding is simply the first function to collapse.

If your first reaction is to adjust glue,

it is like replacing a fire alarm when it goes off—

you are addressing the warning, not the fire.

Core principle:

Under low-grammage conditions, decision order matters more than corrective action.

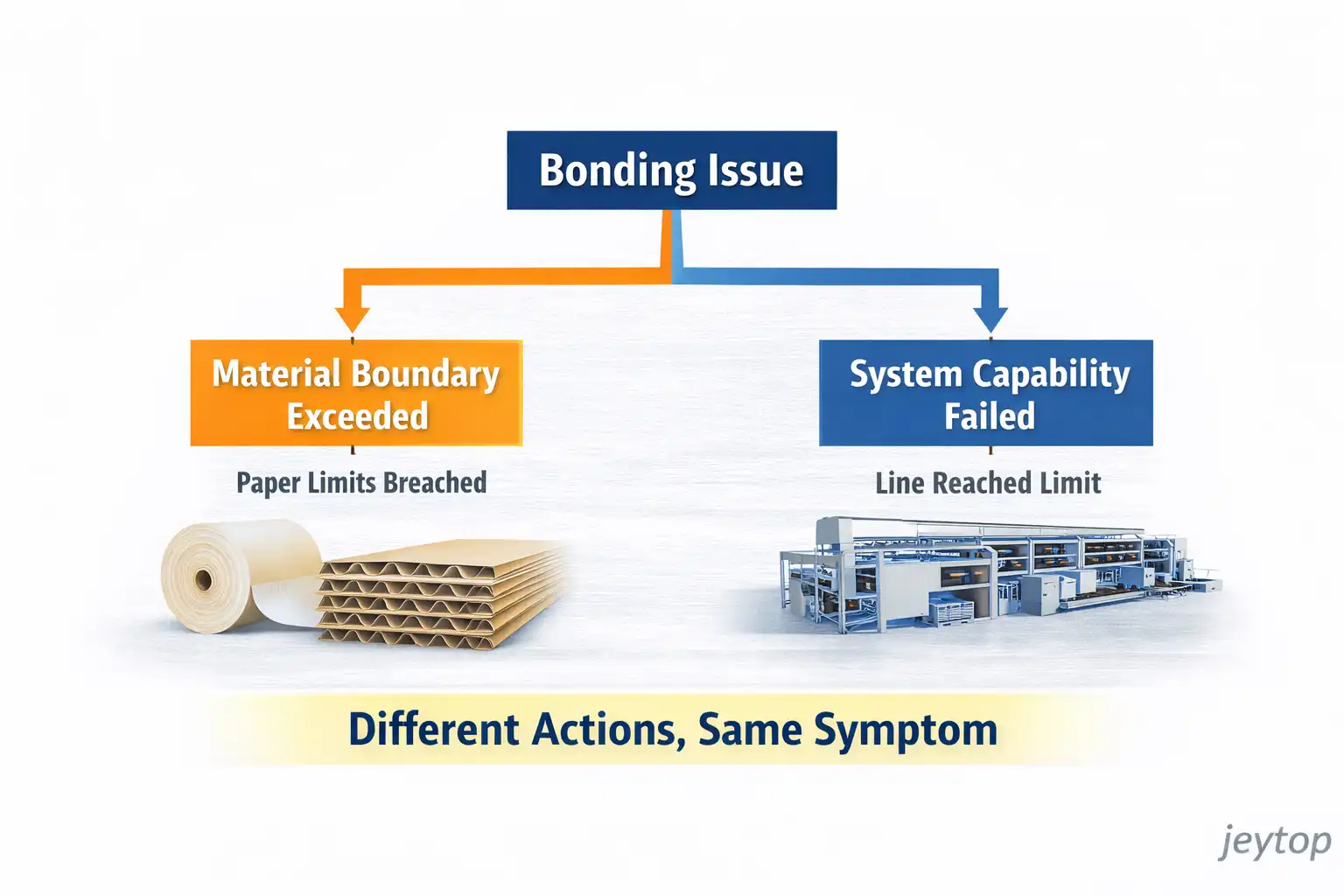

Determine the direction: Has the material boundary been exceeded—or has system capability failed?

This is the non-negotiable decision point.

Your task is not to fix the issue immediately,

but to determine—quickly—whether you should be investigating the paper or the line.

Signals pointing to a material-boundary failure:

- The problem correlates strongly with a specific paper batch or reel

- Bonding deteriorates rapidly after humidity or storage condition changes

- The board’s overall physical feel differs clearly from normal (softer, damper, or unusually brittle)

In many cases, even simple physical observation reveals the direction:

bond failures showing fiber pull-out rather than adhesive separation often indicate the material has reached its functional limit.

These observations are not about how to fix the problem—

they tell you whether the material is still inside a recoverable window.

Signals pointing to a system-capability failure:

- Bonding weakens progressively with speed increases or sustained high load

- Multiple quality indicators degrade simultaneously (flute structure, flatness, bonding)

- Machine parameters appear stable, yet output quality declines gradually over time

This pattern indicates that the system is no longer able to maintain its working window under current conditions.

👉 The sole purpose of Step One is direction locking.

If the direction is wrong, every action afterward compounds the error.

If it’s a material-boundary issue—ask three questions before attempting rescue

If the evidence points to paper limitations, resist the urge to “save” the batch through process adjustments.

Ask these three questions instead:

- Has moisture content entered an uncontrollable range?

- Can the surface condition still accept the current energy input?

- Is the board still within a reversible window—or has permanent degradation begun?

This stage deliberately avoids parameters or corrective recipes.

It is a management decision, not a technical one:

Is this batch worth a high-risk rescue—or should losses be contained early?

Under low-grammage conditions, late acceptance of failure often costs more than early isolation.

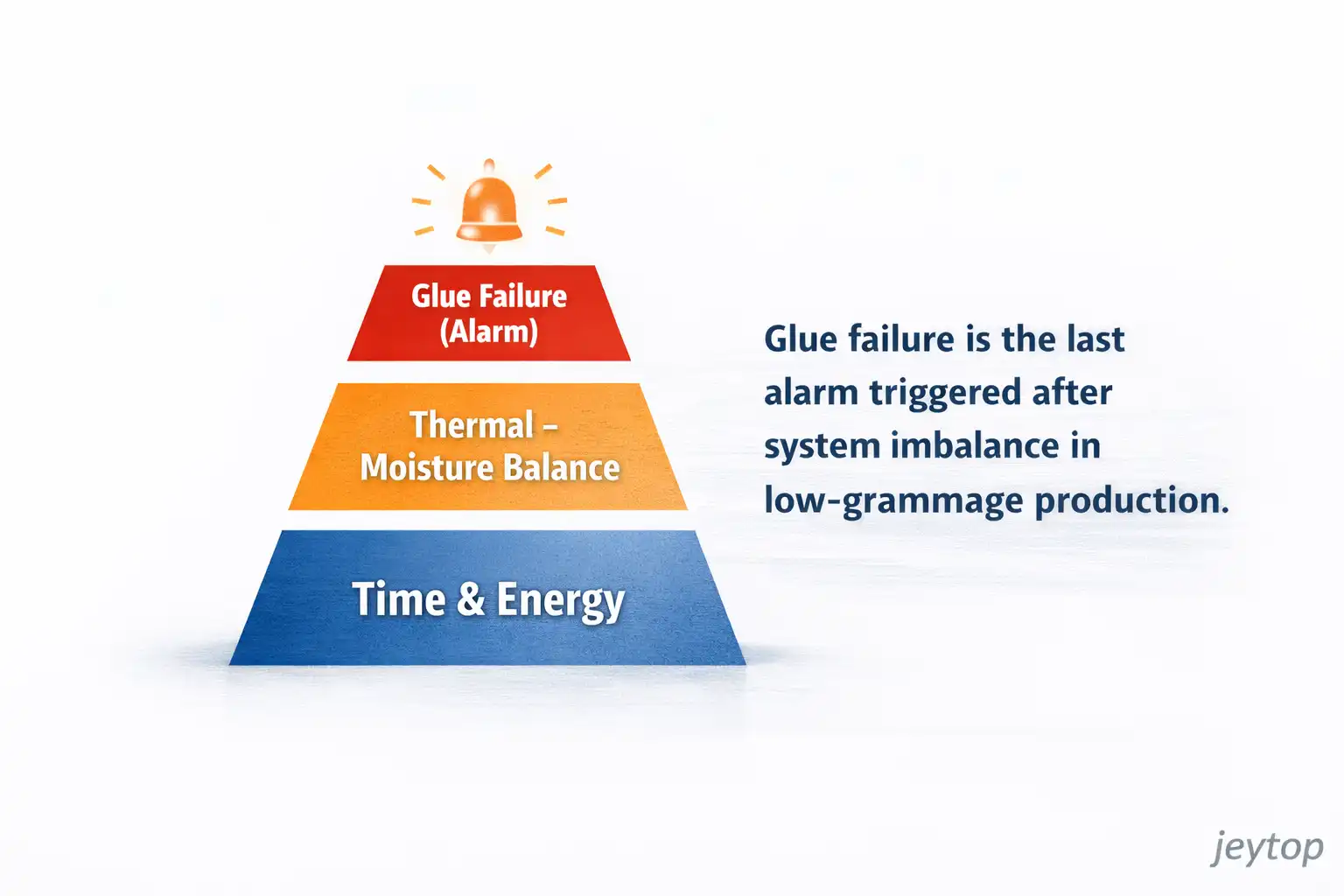

If it’s a system-capability issue—check time and energy, not glue

If the direction points to system limits, move attention away from the glue unit immediately.

Under low grammage, the first constraints to fail are usually:

- Time – insufficient thermal exposure for reactions to complete

- Energy transfer efficiency – heat not reaching the bonding interface effectively

- Thermal–moisture balance – energy consumed by evaporation instead of bonding chemistry

A critical anchor to remember:

In low-grammage production, glue failure is often the last alarm triggered after system imbalance.

Adjusting glue to compensate for system instability only accelerates loss of control.

Three instinctive actions that must be prohibited under low grammage

Before the issue is clearly classified, the following actions are high-risk and must be avoided:

❌ Forcing bonding through increased pressure

→ Permanently damages flute structure and collapses the tolerance window

❌ Chasing the problem with repeated glue adjustments

→ Destroys thermal balance and eliminates diagnostic reference points

❌ Continuing volume production without directional clarity

→ Turns a manageable deviation into a large-scale scrap event

These actions may mask issues in high-grammage production.

Under low-grammage conditions, they terminate system stability outright.

Low grammage is not the problem—it is a decision-discipline filter

Low-grammage packaging is a permanent industry direction.

What it eliminates is not equipment—but outdated diagnostic habits.

When bonding fails under low grammage, the real dividing line is simple:

Can your team determine—quickly—whether the situation is recoverable or must be stopped?

Factories that succeed are not those with the most expensive machines,

but those that convert system understanding into disciplined decision sequences.