If your corrugator suddenly starts producing collapsed flutes, while all displayed settings—speed, temperature, pressure—remain unchanged, stop yourself before reaching for the control panel.

Because what you are facing is very likely not a parameter-setting problem, but a more fundamental signal:

The parameters may be stable, but the system is no longer operating in the same state.

Parameters are the commands you give the machine.

Flute collapse is the physical reality the system gives back to you.

When those two no longer align, the first question is not “what should I adjust?”

It is:

“What has changed in the system—even though the numbers have not?”

Step One: Reset the Mental Model — Parameters Didn’t Change, the System Did

Start with a critical distinction that is often overlooked:

- Parameters are the values you set and see.

- System state is the total physical reality that determines the outcome.

Even with unchanged parameters, system conditions may have shifted:

- A new paper batch with different stiffness or moisture behavior

- Gradual loss of preheater efficiency

- Changes in ambient temperature or humidity

- Altered energy or moisture transfer under the same nominal settings

One rule matters most here:

Unchanged parameters do not mean unchanged conditions.

If this is not recognized early, every adjustment that follows risks being aimed at the wrong target.

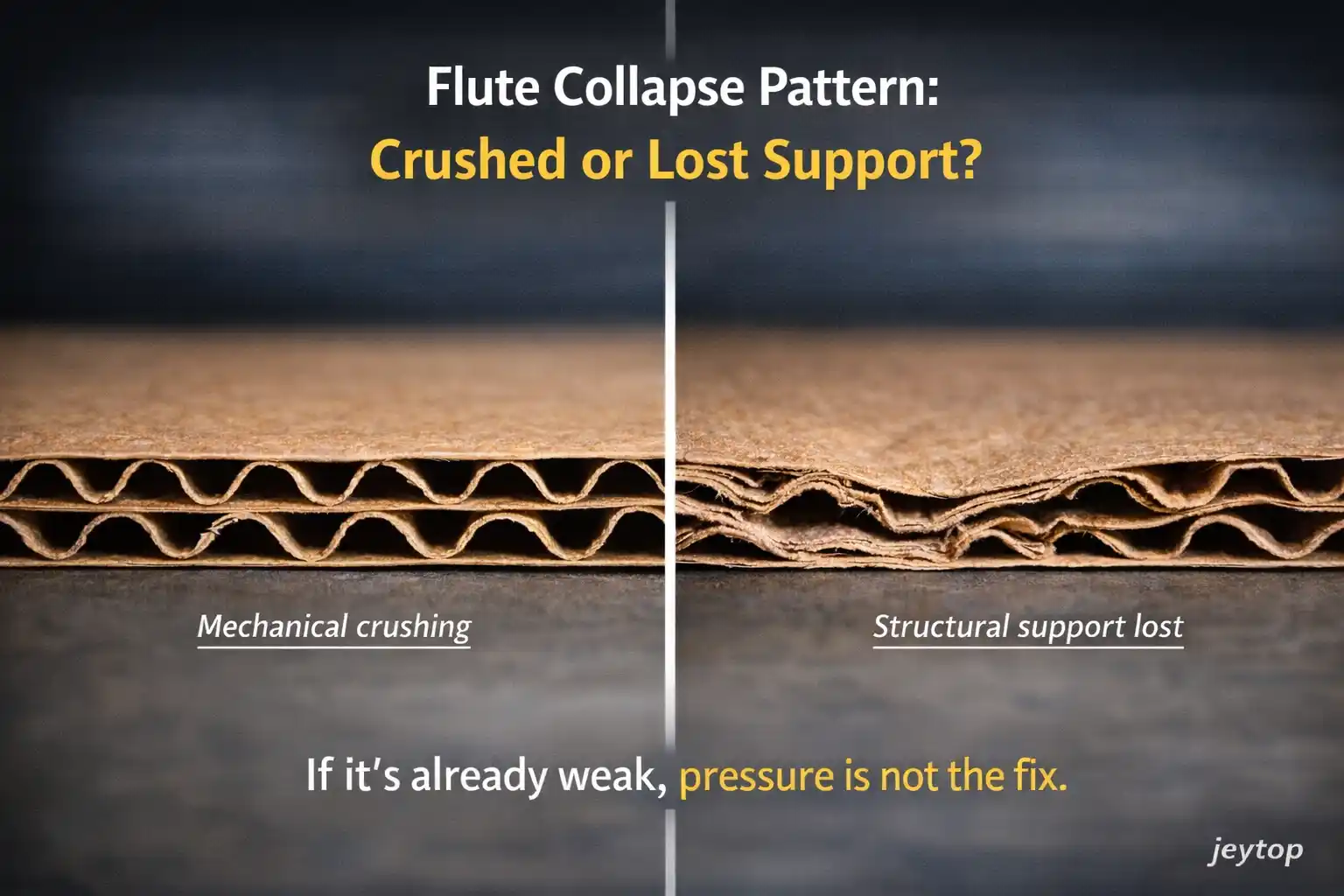

Step Two: Observe the Collapse Pattern — Before Assigning Blame

Without stopping the line or making adjustments, observe how the flute is failing:

- Is the collapse uniform across the full width, or localized and intermittent?

- Does the flute look mechanically crushed, or does it appear soft, weak, and unable to hold shape?

This observation is not about finding the answer.

It is about eliminating false assumptions.

A soft, full-width collapse is rarely a pure pressure issue.

When the flute has already lost its structural support, adding force only accelerates damage.

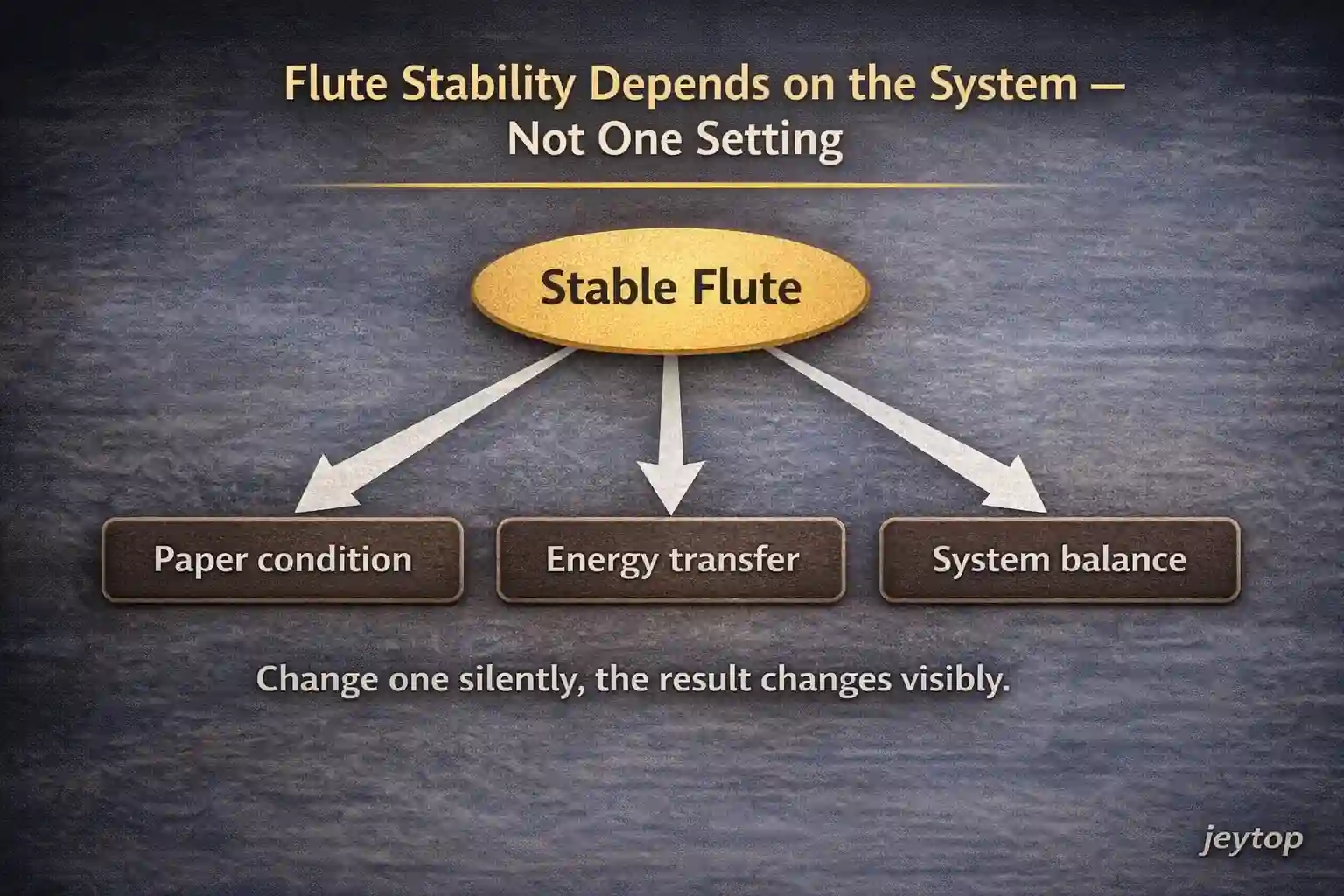

Step Three: Remember a Fundamental Truth — Flutes Are Not “Adjusted” into Shape

A stable flute exists only when three conditions are met simultaneously:

- The paper itself has sufficient structural strength

- Energy input is applied at the correct stage

- External force is not masking an underlying imbalance

If any one of these shifts, flute stability can fail suddenly—

even when parameters appear unchanged.

This is the real meaning behind “nothing was adjusted, but everything went wrong.”

Step Four: Judge the Trend — Not Just the Moment

Now observe how the situation evolves:

- Does the collapse appear suddenly and then stabilize?

- Or does it progressively worsen during continued operation?

This distinction is decisive.

A brief disturbance may be recoverable.

A progressively worsening collapse is a strong signal that the system is sliding out of its stable operating window.

In that case, attempting to “hold it together” with parameter tweaks only increases downstream risk.

Reactions That Must Be Avoided Before the Cause Is Clear

Until the system condition is understood, avoid these instinctive responses:

- ❌ Forcing the flute back with higher pressure

- ❌ Chasing a temporary balance by repeatedly changing speed

- ❌ Compensating blindly with higher heat

Each of these may hide the symptom briefly—

but they amplify the underlying instability.

When a system is already losing balance, parameters will always lose the fight.

The Only Output That Matters Right Now

At this stage, you do not need to know which value to change.

You must answer a more important question:

“Has this flute collapse moved beyond what operational parameters can self-correct?”

That judgment determines the next step:

- Controlled continuation with close monitoring

- Immediate pause and condition freeze

- Escalation to a system-level process review

Final Takeaway

When flute collapse appears while parameters remain unchanged, the machine is not “malfunctioning.”

The system is telling you that your previous assumptions no longer match physical reality.

Mature production decisions are not defined by how fast parameters are adjusted—

but by how quickly one recognizes that the problem is no longer a parameter problem at all.