Do your customers use “heavyweight” boxes to challenge your pricing? Do boxes in your warehouse collapse under stacking pressure, making you question the standards you use? This communication gap stems from using different languages—you speak in scientific data, while they rely on sensory perception.

The Edge Crush Test (ECT test) is the globally accepted scientific language in the packaging industry. Mastering it allows you to end pointless debates about weight and price, elevating the conversation to one about value and safety.

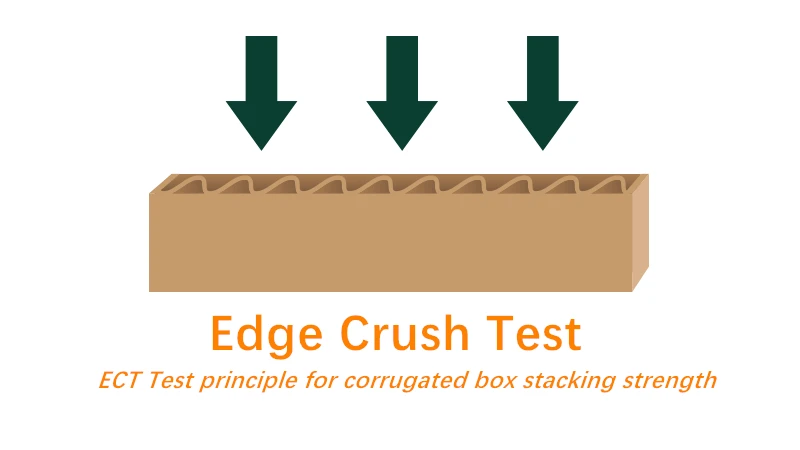

What is an ECT Test? The Scientific “Physical” for Your Box’s Stacking Strength

Judging a person’s strength by their weight is misleading. Similarly, judging box strength by its weight is the most deceptive metric. The true core lies in its Edge Crush Test (ECT test).

- Scientific Definition: It measures the maximum vertical force a unit width of corrugated board edge can withstand before crushing. Units are typically kilonewtons per meter (kN/m) or pounds per inch (lbf/in).

- A Simple Analogy: Think of corrugated board as the “supporting skeleton” of the human body. The ECT test measures how strong this “skeleton” is. The flutes are the bone structure(learn more about flute profiles and board structure); the paper is the bone density. Only a strong skeleton (high ECT value) can support a tall body (a highly stacked box).

- The Bottom Line: Therefore, the ECT value is the definitive medical report for your board’s “supporting skeleton”, scientifically predicting your box’s stacking safety in real-world warehouse environments. Understanding the ECT test is the first step to confident pricing.

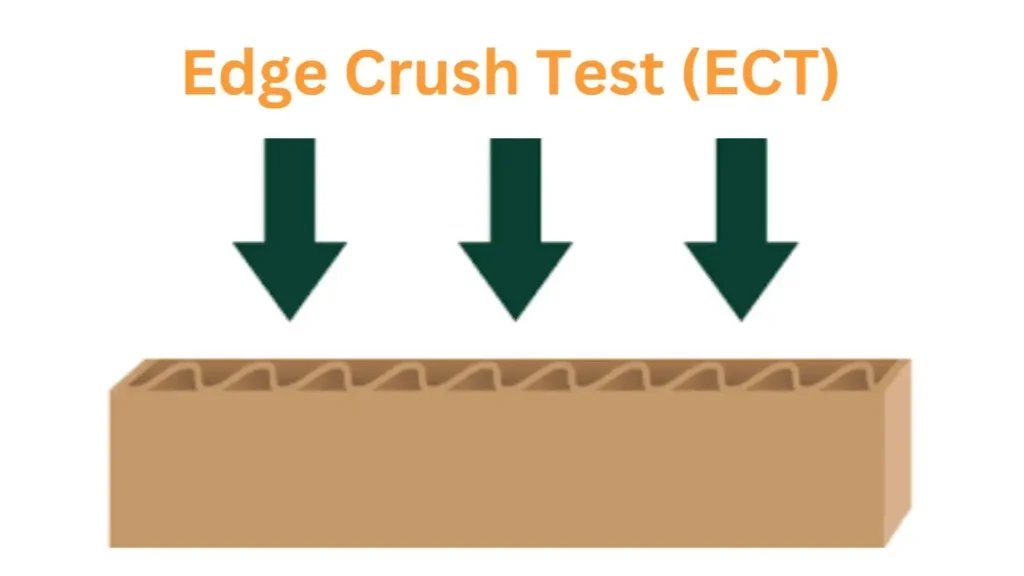

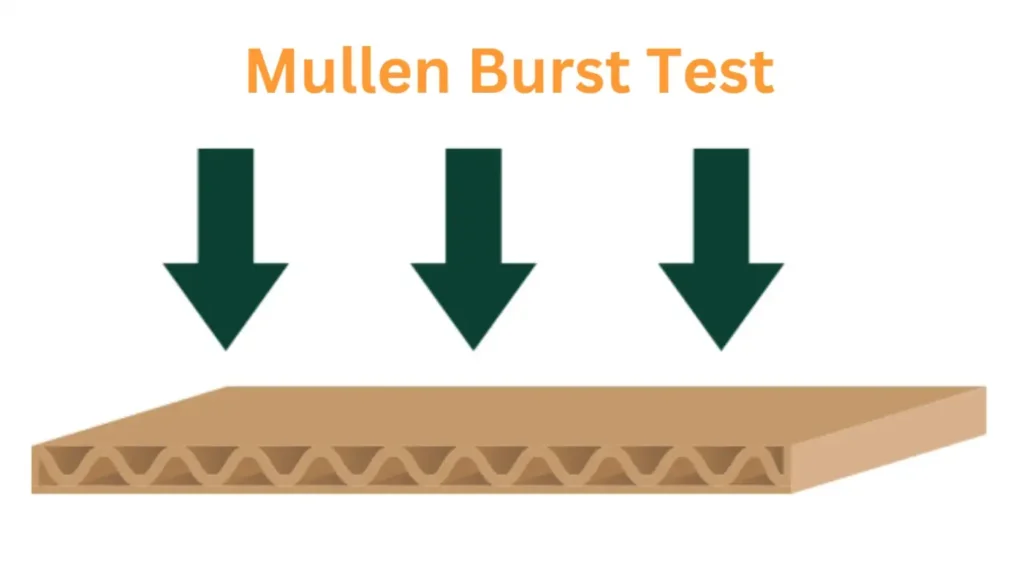

ECT vs Mullen: Clarifying the Boundary Between “Stacking Safety” and “Puncture Resistance”

Confusing ECT with Mullen is a primary cause of incorrect box selection and communication breakdown, often because the ECT test is mistakenly used to judge puncture resistance. They measure box performance in different scenarios.

Remember this analogy:

- Imagine a high-speed highway accident.

- ECT (Edge Crush Test) concerns the structural strength of the roof, ensuring it protects occupants if the vehicle rolls over. This corresponds to your box’s stacking strength and compression resistance.

- Mullen Test (Bursting Strength) concerns the impact resistance of the doors, preventing objects from piercing the cabin. This corresponds to your box’s resistance to puncture and sudden impact.

| Your Focus | When the Core Need Is | The Scientific Standard To Use |

|---|---|---|

| ECT (Edge Crush Test) | Optimizing warehousing costs, eliminating stack collapses | ECT Test |

| Mullen Test | Protecting sharp/fragile contents, handling rough handling | Mullen Test |

Decision Guide: If your and your customers’ pains stem more from “boxes being crushed in the warehouse,” then ECT is the gold standard you must master, and the Edge Crush Test is your proof point.

ECT in Action: Selection Charts, Sales Scripts & Calculations

The tools below will help you immediately turn ECT knowledge into a business advantage. This is where the ECT test moves from theory to profit.

ECT Rating Chart for Quick Selection

This ECT rating chart helps you move from guesswork to data-driven recommendations. Use it to justify your proposals and educate your clients.

| Your Customer & Application Scenario | Recommended ECT Rating | Your Value Proposition (What to Say to Your Customer) |

|---|---|---|

| E-commerce Parcels / Lightweight Inner Boxes | ECT 31+ | “This is the cost-king for e-commerce shipments. It ensures transit safety while optimizing your per-box packaging cost to the minimum.” |

| General Retail / Standard Warehousing | ECT 44+ | “This rating reliably handles 3-4 meter warehouse stacking, providing a dependable ‘safety margin’ to effectively prevent collapse losses.” |

| Heavy Industrial Parts / High-Stacking | ECT 55+ | “For your valuable heavy products, this level provides ‘insurance,’ minimizing the risk of damage during transit and high stacking.” |

| Premium Gifts / Brand Display | ECT 44+ (with E/F Flute) | “This combination ensures a rigid, premium feel while providing a perfect surface for high-definition printing, significantly enhancing brand image.” |

Referencing this ECT rating chart during discussions instantly elevates your professionalism.

Value-Based Sales Script Templates

- For “Price-Sensitive” Customers:

- Customer’s Point: “Your competitor’s box is heavier and cheaper.”

- Your Response: “I understand your focus on cost. But the key to box protection isn’t weight; it’s stacking strength (the ECT value). Our ECT 44 box is significantly stronger than standard ECT 31 boxes. This means you can increase your warehouse storage density by ~20% and fundamentally reduce the risk of collapse-related damage. The total cost it saves you far outweighs the box price difference.”

- For “Quality-Worried” Customers:

- Customer’s Point: “My current boxes keep getting crushed. Can you guarantee yours won’t?”

- Your Response: “That’s a critical question. We use ECT test data to ensure exactly that. Based on your product and stacking height, we’ve matched you with an ECT 55 solution. Its compression strength is scientifically calculated to meet your needs. We can include this ECT standard in our quality agreement as our commitment to you.”

Quick Stacking Strength Estimate

You can use this rule-of-thumb formula, derived from the principles behind the ECT test, for a quick assessment:

BCT (kg) ≈ ECT Value (kN/m) × Box Perimeter (m) × 5.5

- Example: A box with ECT 44 and a 2-meter perimeter has an estimated stacking strength of: 44 × 2 × 5.5 = 484 kg.

- Note: This is an empirical estimation based on industry models for quick comparison. Precise design requires considering humidity, aspect ratio, dynamic loading, and other factors.

Ensuring ECT Stability: Bridging the Gap from Knowledge to Reliable Production

Mastering ECT knowledge and negotiation tools puts you ahead of the market. But the next challenge arises: How do you ensure every sheet of board you produce stably meets the ECT standard you promise your customers?

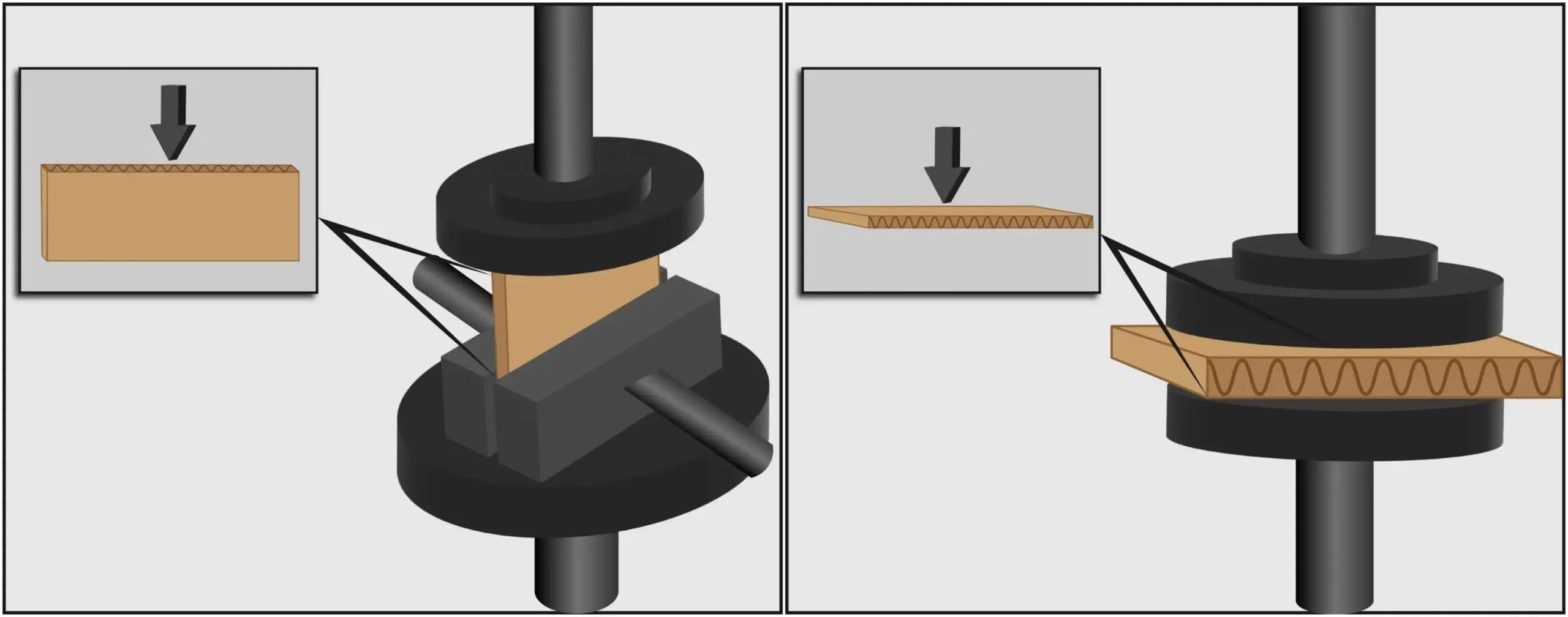

The root cause of ECT fluctuation often lies deep within the production line’s “flute formation” stage. The entire value of the Edge Crush Test is undermined if the board’s foundational structure is inconsistent.

Corrugated board derives its strength from its perfect “arch structure” (the arch bridge principle). If flutes are crushed, uneven, or poorly bonded during formation(a common issue we help solve here), it’s like cracking the arch bridge, drastically reducing the board’s edge crush strength (ECT).

Locking in ECT stability requires not post-production fixes, but extreme control over “flute formation precision” at the source.

In Cangzhou, Hebei—a core hub of China’s corrugated machinery manufacturing—we understand this deeply. At Jeytop, we focus our manufacturing expertise on the foundation of precision:

- We self-manufacture core corrugating rolls and pressure rolls, ensuring every engagement “sculpts” perfectly uniform flutes in shape and height.

- Our self-developed forming stations and control systems maintain this precision consistently at high speeds, eliminating any hidden flute damage caused by machine vibration.

For you, this translates to:

- Using more economical paper to stably produce board with higher, more consistent ECT values, achieving tangible material cost savings.

- The ability to confidently sign long-term quality agreements with your customers, thanks to product quality that is consistent over time, eliminating complaints and reputation loss due to fluctuations.

This system, from core components to full-line control, is the practice of the Jeytop Integrated Manufacturing Model—ensuring we deliver not a “collection of parts” needing constant adjustment, but a deterministic production system ready to reliably output high-quality board from day one.

Your Next Step

Option 1: Get Your Complete “ECT Application & Negotiation Guide”

We’ve systematized the tools from this ECT test guide and prepared deeper, exclusive content:

- Extended ECT Rating Chart: Covering specialty sectors like chemicals and cold chain.

- Full-Scenario Sales Scripts: Complete dialogue templates for phone, email, and meetings.

- Precision Calculation Tool & Case Library: Step-by-step tutorials with real cases.

Contact us to get the free, complete Playbook for immediate team training.

Option 2: Get a Free “Preliminary Optimization Plan” for Your Factory

If you face specific ECT fluctuation or cost pressures:

- Provide your main paper grades, target ECT value, and current pass rate. Our engineers will generate a free Preliminary Optimization Plan based on our vast project database.

- The plan includes: Achievable ECT improvement targets, corresponding core equipment upgrade advice, and expected ROI analysis.

This moves beyond generic consultation to a results-oriented, tailored analysis.