When board thickness suddenly becomes unstable—leading to inconsistent creasing depth, uneven stacking, and immediate complaint risk—stop before touching any machine adjustments.

At this moment, the most important task is not to “bring thickness back into range.”

You must first answer a far more fundamental decision question—within three minutes:

Is the thickness instability caused by a change in the paper input,

or by a loss of stability in the machine system itself?

Choosing the wrong direction leads to wasted adjustments, unnecessary maintenance, and often a cascade of secondary process failures.

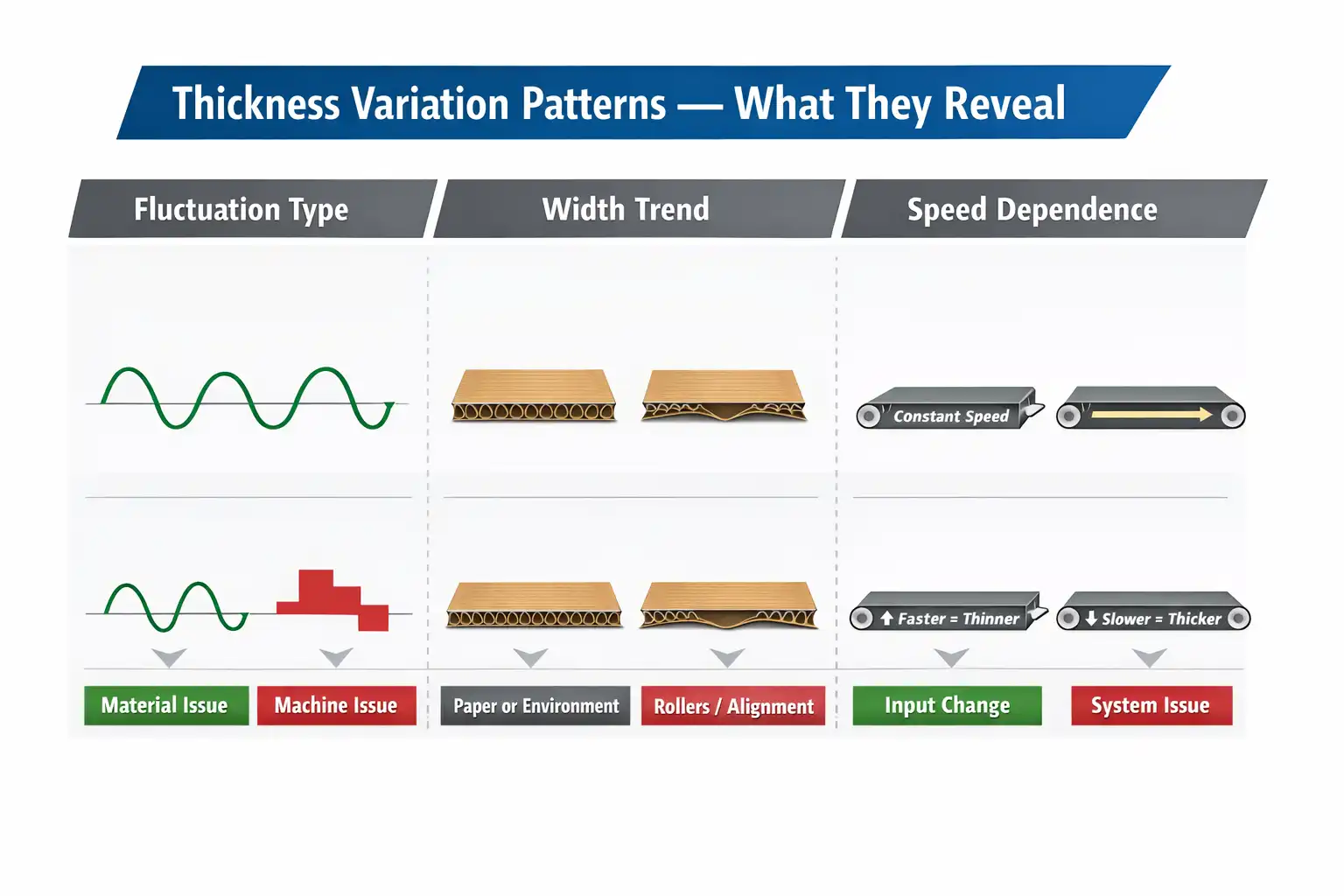

Minute One: Observe the Pattern, Not the Number

Thickness problems are rarely numerical problems first.

They are pattern-recognition problems.

Use one minute to make these three observations:

1. Is the variation gradual or sudden?

- Gradual, smooth fluctuation → typically material-related (moisture, compressibility)

- Sudden jumps or step changes → typically machine response or mechanical instability

2. Is the variation uniform across the board width?

- Same trend from edge to edge → strongly suggests paper or environmental influence

- Center thin / edges thick, or left-right imbalance → enter machine pressure or roll alignment diagnosis

3. Is thickness strongly speed-dependent?

- Thickness fluctuates while speed is constant → input conditions are changing

- Thickness changes immediately and repeatably with speed changes → classic machine response issue

Goal of minute one:

Determine whether the input is drifting or the system is losing stability.

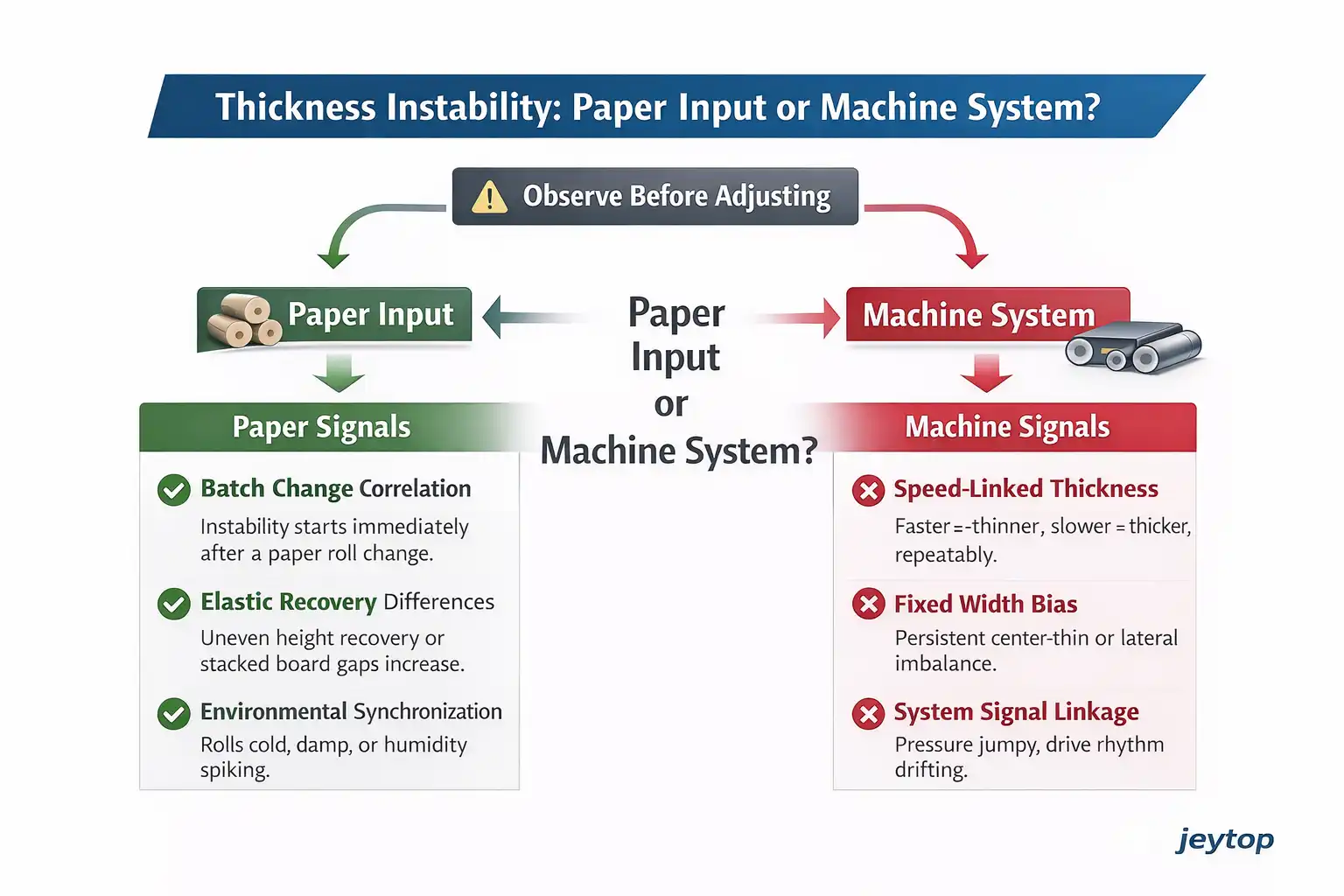

Minute Two: Signals That Point to a Paper Issue First

If one or more of the following signals are present, paper must be your primary suspect:

Paper batch correlation

Thickness instability starts immediately after a paper change, while machine settings remain unchanged.

Machines do not selectively fail only for one paper batch—this correlation matters.

Elastic recovery differences

After compression, boards recover to different heights.

Stack height variation increases over time.

This directly reflects paper fiber structure and compression modulus.

Environmental synchronization

Problems appear after sudden humidity or temperature changes.

Paper rolls feel noticeably colder or damper by hand.

Paper is a direct responder to environment; machines are not.

Conclusion at this stage:

When thickness instability is global, batch-linked, and environment-sensitive, adjusting the machine only masks the real issue.

Minute Three: Signals That Lock the Root Cause to the Machine

Shift focus to the machine system when these signals appear:

Repeatable speed-linked behavior

Every speed increase makes the board thinner; every slowdown makes it thicker (or vice versa).

This pattern is typical of pressure system lag, inertia effects, or synchronization mismatch—not paper behavior.

Fixed cross-machine location bias

Persistent center-thin or edge-thin patterns.

Paper defects rarely present as fixed, asymmetric thickness profiles.

This points to roll wear, crown issues, bearing clearance, or uneven thermal distribution.

Thickness instability accompanied by other machine symptoms

Pressure readings fluctuate without setpoint changes.

Drive rhythm or downstream timing (such as cut-off synchronization) also becomes unstable.

Thickness is acting as an early system health indicator.

Conclusion at this stage:

When thickness instability shows position dependence, speed coupling, and system signal linkage, the root cause is almost certainly mechanical or control-related.

Actions That Must Be Avoided Before the Cause Is Clear

Until paper vs. machine is clearly determined, the following actions are prohibited:

❌ Forcing stability by increasing pressure

→ Permanently damages flute structure and triggers downstream bonding and strength failures

❌ Repeated parameter changes to “compensate” guesses

→ Moves the entire system onto a drifting reference baseline

❌ Running while making undocumented, experience-based micro-adjustments

→ Destroys the diagnostic baseline and removes all traceability

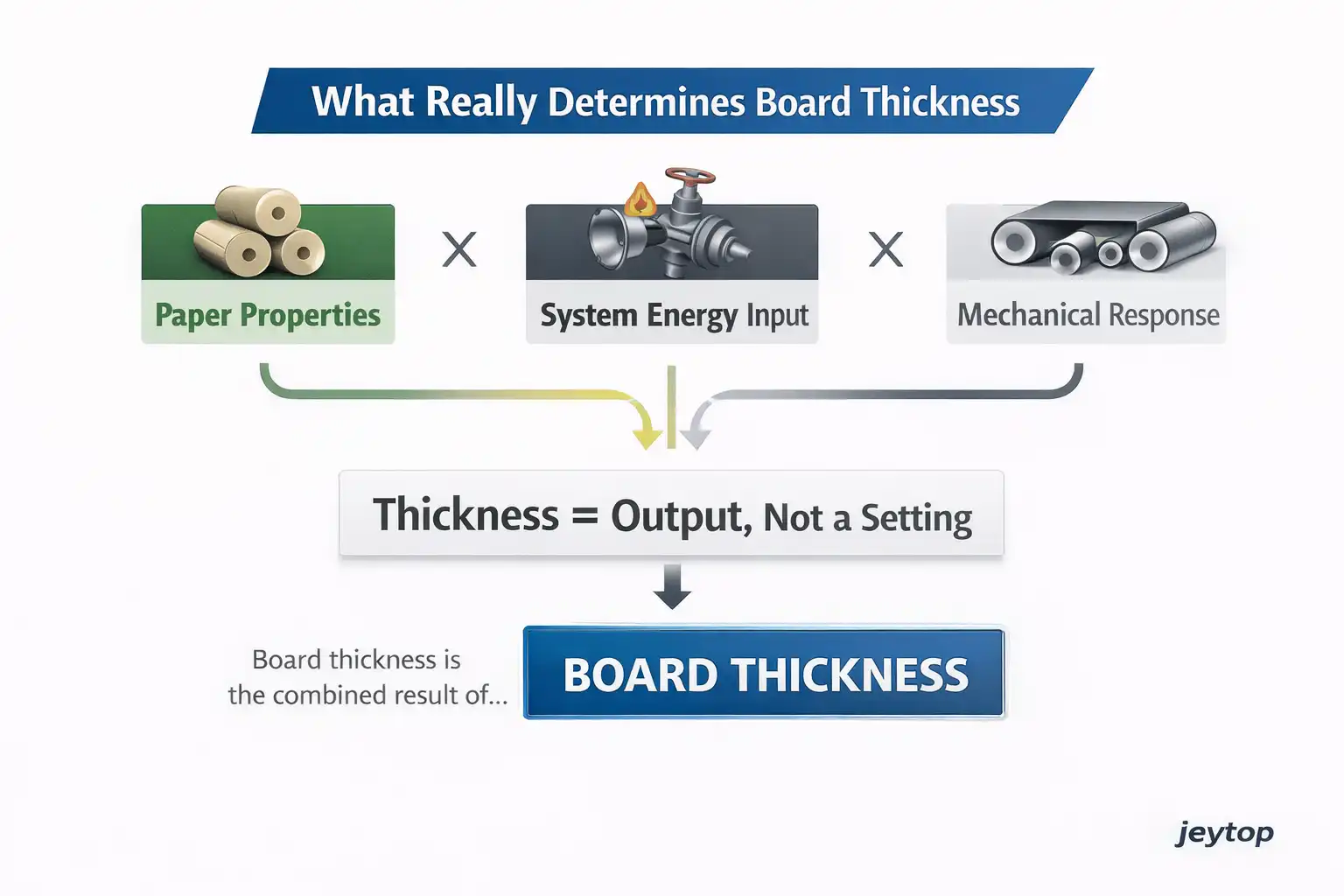

The System Model You Must Hold

Board thickness is not a standalone setting.

It is the combined output of:

Paper inherent properties × System energy input × Mechanical response accuracy

Mature operational thinking does not ask:

“How thick is it now, and how do we push it back?”

It asks first:

Has the input function changed, or has the system function degraded?

Final Takeaway

Thickness instability is never an isolated quality defect.

It is the production system communicating with you.

Either the material has moved off its expected path,

or the system’s ability to process stable input has degraded.

Teams that can make the paper vs. machine judgment within the first three minutes

prevent quality escalation before it spreads downstream.

That is where real production certainty begins.