When you open a shipping carton, only to find the product inside damaged due to failed packaging—it’s more than a financial loss; it’s a breach of trust with your customer.

Often, the root cause isn’t just rough handling, but a failure starting from the very core of the packaging: the Corrugated Board. This guide will walk you through its fundamentals, helping you mitigate risks at the source and make more informed packaging decisions.

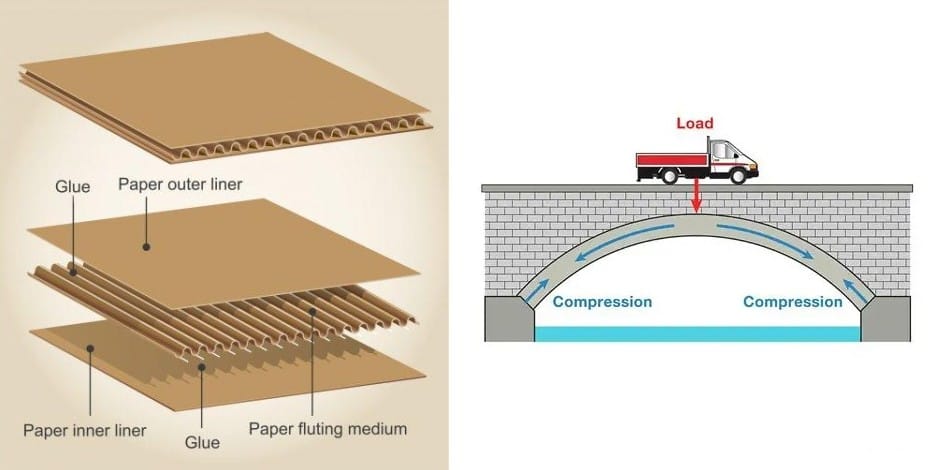

1. Corrugated Board Structure: The “Sandwich” and “Arch Bridge” Explained

The protective power of corrugated board comes from its clever composite structure:

- The Flat Liners: The outer and inner liners provide a smooth printing surface and initial strength.

- The Fluted Medium: The wavy, arched paper is firmly glued between the liners, creating regular channels.

The secret lies in this fluted, wave-like shape, which utilizes the classic Arch Bridge Principle. Just as an arch bridge distributes immense weight and pressure, the fluted structure disperses and absorbs external shocks and stacking forces, delivering maximum support and cushioning with minimal material.

2. Corrugated Board Types: Flute Profiles and Wall Construction

Knowing the basic structure is the first step. Understanding its different types will help you meet diverse packaging needs.

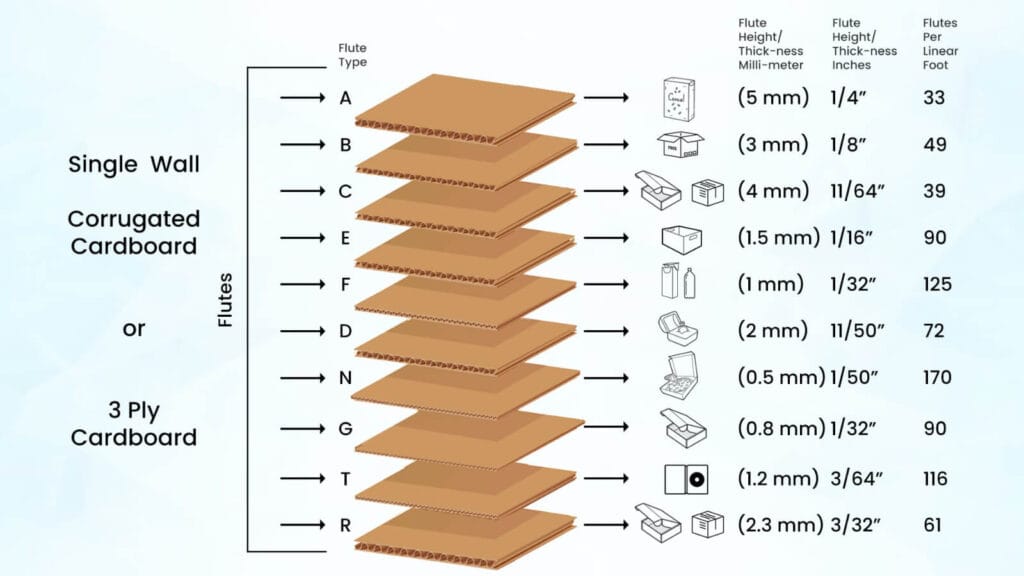

2.1. By Flute Type

The differences between flutes lie in their flute height and the number of flutes per unit length, which directly determine the board’s characteristics:

| Flute | Core Characteristics | Typical Applications |

|---|---|---|

| A-Flute | Highest cushioning, excellent vertical compression strength | Fragile items, glass, precision instruments |

| B-Flute | Good puncture and flat crush resistance, superior printing surface | Canned goods, beverages, retail-ready packaging |

| C-Flute | A versatile “all-rounder,” balancing cushioning and compression | The go-to choice for general shipping cases |

| E-Flute | Thin, rigid, offers a high-quality, premium feel | Consumer electronics, cosmetics, food packaging |

| F-Flute | Ultra-thin for a sleek, superior surface and tactile experience | Luxury goods, high-end gift boxes |

Beyond these common types, specialized flutes like N, G, and D serve niche applications. N and G flutes are even thinner than F flute, approaching cardstock thickness for ultra-premium micro-packaging. D flute finds use in specific industrial cushioning due to its unique stiffness. Knowing these options broadens your horizon for specialized packaging challenges.

(For a detailed guide on selecting the right flute, see our resource: [Choose Your Corrugated Flute in 5 Mins].)

2.2. By Wall Construction

- Single-wall: Three layers. The most common and cost-effective, suitable for most inner boxes and shipping cartons.

- Double-wall: Five layers. Allows for flute combinations (e.g., BC-flute), balancing strength with a flat surface for heavy-duty or high-end retail packaging.

- Triple-wall: Seven layers. Used for heavy-duty industrial packaging, providing unparalleled compression and puncture resistance.

Furthermore, custom multi-wall boards with even more layers can be engineered to withstand extreme shipping and storage environments.

3.Corrugated Board Performance: From Structure to Value

Choosing a corrugated board structure that matches your product delivers direct, tangible benefits:

- Superior Cushioning & Protection: The “arch bridge” air columns provided by A, C, and other flutes effectively absorb shocks and vibrations during transit, directly reducing your product damage rate.

- Powerful Stacking Strength (Box Compression Strength): Multi-wall constructions like double and triple-wall ensure stable, secure pallet stacking in the warehouse, optimizing your storage space.

- Excellent Printability: The flat surfaces offered by B and E flutes provide the ideal canvas for high-definition brand printing, enhancing your product’s perceived value.

Troubleshooting Common Production Issues

However, a perfectly designed board can still lead to problems on the production floor:

- Warped Board? This is often not a design or material issue, but a direct result of inconsistent adhesive application, improper preheating, or inaccurate moisture control on the production line.

- Insufficient Strength? Even with qualified paper, the final Edge Crush Test (ECT) value might be low. This is likely due to poor flute formation, where the flutes fail to achieve the designed height, preventing the “arch bridge” from realizing its full supportive potential.

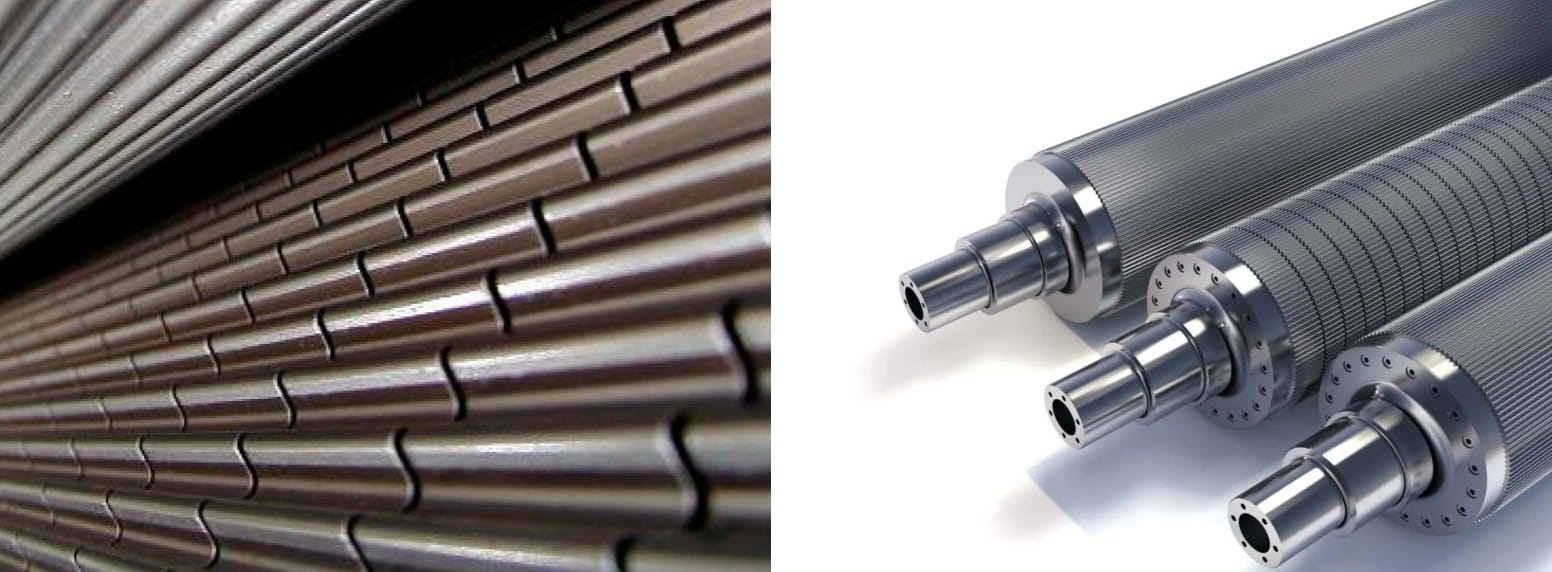

The root of these issues typically points to the same factor: the precision, stability, and control capabilities of the production equipment.

Why Your Production Line is the “Silent Guardian” of Packaging Quality

You can select premium paper and the ideal flute profile, but if your production equipment lacks precision, all these advantages are lost during manufacturing.

- When equipment is imprecise, you face more than just rejects:

- Hidden Cost Drain: Every warped sheet, every irregular flute is silently burning your money through wasted material and downtime.

- Unpredictable Schedules: Frequent machine adjustments and repeated process tweaks make a mockery of your production planning.

- Brand Reputation at Risk: Inconsistent packaging quality ultimately reaches your customer, bearing your logo.

- A “reliable” machine should perform like a “reliable” right hand:

- It faithfully executes your process settings, transforming raw materials into the perfect board you designed.

- It delivers consistent output, ensuring the first and last unit in a run are identical, allowing you to promise quality to your customers confidently.

- It responds swiftly, minimizing changeover waste and downtime when you need to switch product specifications.

At Jeytop, we are committed to building such a “reliable right hand” for your business. Our Integrated Manufacturing model is fundamentally a promise of Determinacy—ensuring the equipment you receive can consistently and stably produce high-quality corrugated board for you, eliminating quality losses and cost overruns caused by machine variability at the source.

Your Next Step

Corrugated board quality is a systems engineering achievement, depending on the perfect synergy of material, design, and manufacturing process.

- To dive deeper into the details, we have prepared a complete knowledge series, including [Choose Your Corrugated Flute in 5 Mins] and [Corrugated Board Grades How to Choose Paper Weight].

- If you are grappling with board quality fluctuations, high waste rates, or inefficient production, it’s often a clear signal that your equipment may no longer meet your quality ambitions. We are happy to leverage our experience to help you diagnose the root cause and explore viable solutions.

We are ready to discuss the specific challenges you are facing.