Corrugated board defects are often the root cause of the most frustrating production issues in a box plant, such as blurry printing and adhesive failures on the folder-gluer. You might have checked the ink, glue, and operators, only to find the problem lies at the very source—your corrugated board might be coming off the production line with these hidden flaws.

These Common Headaches Point to Underlying Defects

The problems you face are classic symptoms of specific corrugated board defects:

- Unclear Printing Damages Client Trust

Imagine printing a logo with fine gradients, only to get patchy colors and fuzzy text. Often, this isn’t a printer issue. It’s a fundamental flaw in the board itself—a warped corrugated board creates an uneven surface, preventing proper ink transfer. - Glue Failures Kill Your Efficiency

Your team calibrates the folder-gluer, but it never holds. Boxes fail as one side bonds while the other peels open. Frequently, this box sealing glue failure stems from an uneven board surface causing inconsistent pressure application. - Hidden Weaknesses Lead to Costly Surprises

Lab tests show good Edge Crush Test (ECT) scores, but boxes collapse in the warehouse. This points to inconsistent corrugated board stiffness caused by poorly formed flutes during production—a hidden defect that leads to product damage and claims.

These defects all originate from a lack of precise control on the cardboard production line.

The Root Cause: Mastering Three Critical Control Points

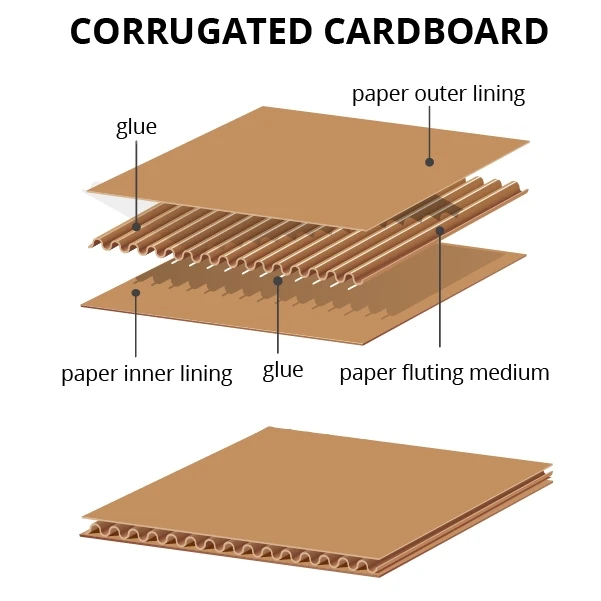

Eliminating these common corrugated board defects requires expert control over three pillars of your cardboard production line: (This connects deeply to your understanding of Corrugated Board Guide: Structure, Types, and Performarnce.)

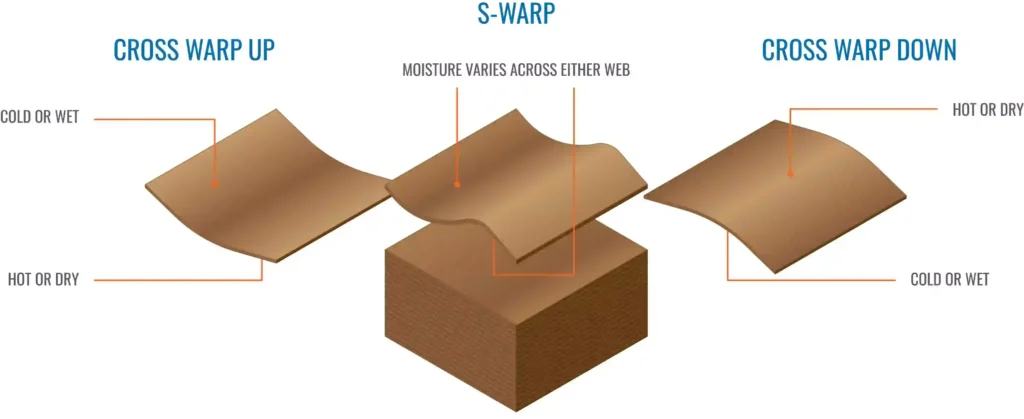

- Uncompromising Flatness

Corrugated board is fused under heat and pressure. Even minor inconsistencies in temperature or pressure across the line’s width create internal stress, manifesting as warping. You need a system capable of real-time monitoring and automatic adjustment. - Precision in the Glue Line

The glue line acts as the board’s critical “tendon.” Inconsistent application creates weak points. You need an intelligent gluing system, immune to production speed variations, that delivers a perfectly uniform glue line. - Unshakable Synchronization

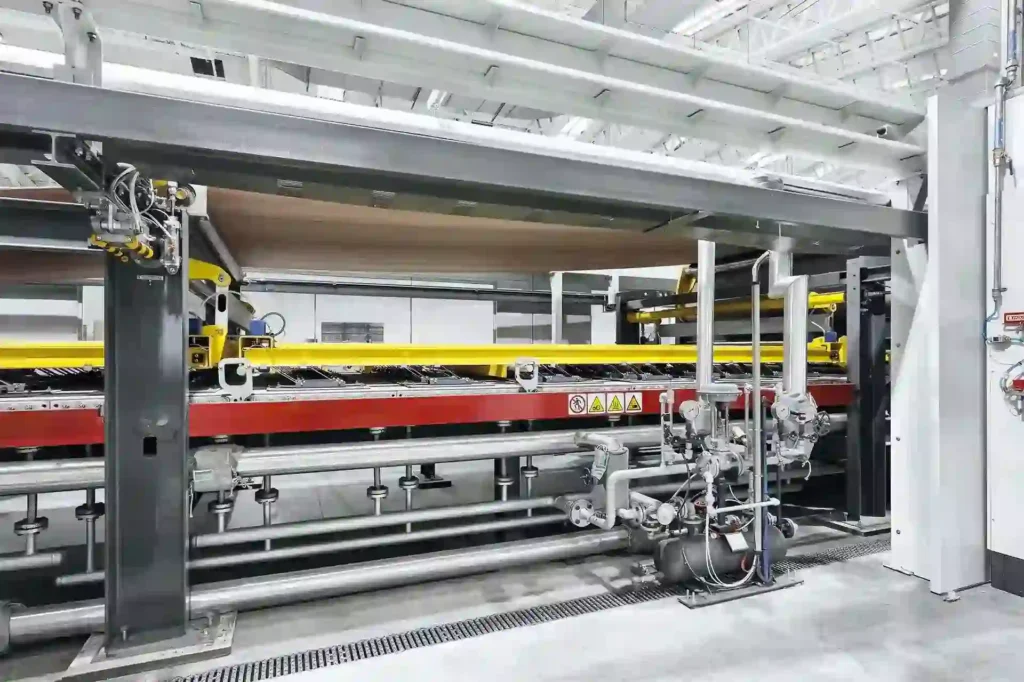

A production line is an orchestra. If the single facer, double backer, and cutter are not in perfect sync, the final product suffers. You need a powerful “command center” to ensure stable, coordinated operation.

How to Systematically Eliminate Defects at the Source

When blurry printing and glue failure keep recurring, you need more than a new machine; you need to eliminate the “internal injuries” at the source.

- To Achieve Flawless Flatness for Perfect Printing

This requires precise control of the thermal balance. By deploying a network of high-precision sensors and automatic compensation mechanisms at key points, we can significantly suppress warping variation. For you, this means your printers receive a stable, qualified substrate, drastically reducing customer returns and material waste caused by blurring and flute-show. - To Eliminate Persistent Glue Failures for Good

The key is a gluing system that precisely follows every speed change. The servo-driven intelligent gluing system we employ ensures a consistent and reliable glue line across mainstream production speeds. This directly helps you lower waste rates and save on board and glue costs. - To Prevent Unexpected Box Collapse in the Warehouse

Guaranteeing consistent box strength requires stable flute formation. Our control system with integrated synchronization algorithms acts as the “conductor,” enhancing the stability of the entire line. This results in boxes with uniform supportive strength, directly reducing your product damage and customer claims from hidden collapse.

However, even the best individual components cannot eradicate problems if they fail to work as one cohesive unit. You may have experienced the headache of coordinating a “franken-line” of mismatched equipment. This is where the Jeytop Integrated Manufacturing model delivers its core value: we ensure that every link in the chain—from heating and gluing to synchronization—adheres to a unified high standard and works in seamless concert.

The goal is simple: to deliver to you not a collection of machines that need constant tweaking, but a ready-to-run “production system” that reliably outputs high-quality, low-defect board from day one, directly slashing your commissioning costs and downtime.

Quick Self-Check: Is Your Production Line Hiding These Defects?

Take two minutes to review the common symptoms below. If you check any of them, it’s a clear sign that underlying corrugated board defects are impacting your bottom line.

| Problem Area | Quick Self-Check Questions (Check if Yes) | It Often Points To… |

|---|---|---|

| Printing Quality | □ Is printed graphics or text blurry? □ Does the board surface look wavy? □ Are ink colors uneven? | Poor board flatness due to unstable thermal balance on the production line. |

| Box Sealing | □ Does glue fail on one side of the joint? □ Is the glue line uneven or broken? □ Does gluing performance vary for no reason? | Imprecise glue application that can’t adapt to machine speed changes. |

| Box Strength | □ Do empty boxes deform when stacked? □ Does the board edge feel soft? □ Do boxes collapse in the warehouse? | Unstable flute formation caused by poor synchronization between line sections. |

Solved the puzzle? Let’s fix it.

You’ve just identified the symptoms. Now, let Jeytop’s engineering team help you diagnose the root cause and provide the solution.

Schedule a Free Technical Consultation