In packaging, printing, and logistics, corrugated cardboard thickness is a key factor that directly affects product protection, production compatibility, and transportation costs. However, with varying measurement units and flute types, understanding how thickness works can be confusing. This article provides a comprehensive, data-driven overview to help buyers, engineers, and packaging professionals make informed decisions.

What Is Cardboard Thickness?

Cardboard thickness refers to the depth of the board material, typically measured in millimeters (mm) or points (pt). Some manufacturers also refer to GSM (grams per square meter), which measures weight, not thickness—but the two are often related.

| Unit | Description |

|---|---|

| mm | International standard; 1 mm = 1000 microns |

| pt | 1 pt = 0.001 inch (25.4 microns), used in North America |

| GSM | Measures weight; thicker boards tend to have higher GSM |

Example: A 1.2 mm cardboard might have a GSM between 350–400 depending on material density and layers.

Common Cardboard Types and Thickness Ranges

Paperboard / Solid Board / Chipboard

- Thickness: 0.3 mm – 1.5 mm

- GSM Range: 200 – 450 gsm

- Applications: Folding cartons, cereal boxes, pharmaceutical packaging

- Notes: Excellent for fine printing and die cutting, not ideal for structural strength.

Corrugated Cardboard (Fluted Board)

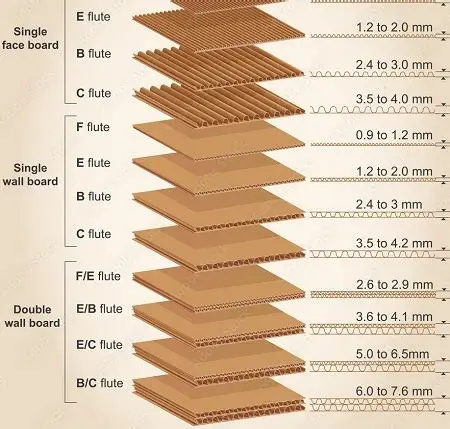

Corrugated board is made from a fluted inner layer sandwiched between two flat liners. Its thickness is determined by the flute type, which also affects durability and flexibility.

Flute Types and Their Standard Thicknesses

| Flute Type | Approx. Thickness | Flutes per Meter | Typical Use |

|---|---|---|---|

| A Flute | ~4.8 mm | ~105 | Maximum cushioning, fragile goods |

| C Flute | ~3.6 mm | ~120 | Most common shipping cartons |

| B Flute | ~2.5 mm | ~150 | Better crush resistance, compact boxes |

| E Flute | ~1.5 mm | ~295 | Retail packaging, high-quality printing |

| F Flute | ~0.8 mm | ~350 | Luxury boxes, small packaging applications |

Flute Combinations (Double & Triple Wall)

| Combo Type | Thickness Range | Applications |

|---|---|---|

| BC Flute | ~6.5 – 7 mm | Heavy shipping, industrial boxes |

| EB Flute | ~4 – 4.5 mm | Retail and e-commerce packaging |

| AC Flute | ~7.5 mm | Large cartons, export packaging |

| AAA Flute | >12 mm | Triple-wall for very heavy or large equipment |

Note: More flutes = more strength but also higher material and shipping cost.

How Is Cardboard Thickness Measured?

Cardboard thickness is typically measured using:

- Calipers or Micrometers (manual)

- Digital Thickness Gauges

- Inline sensors on automated production lines

Measurements should be taken at room temperature and away from creased or compressed areas to ensure accuracy.

Cardboard Thickness vs GSM vs Strength

- GSM tells you how heavy the board is per square meter, not necessarily how thick or strong it is.

- Thickness gives a physical dimension, useful for machine compatibility and space planning.

- Strength is best measured via:

- Edge Crush Test (ECT) – compression resistance

- Burst Strength (Mullen Test) – puncture resistance

A 250 GSM corrugated board can be thicker and stronger than a 350 GSM paperboard due to its flute structure.

Why Cardboard Thickness Is So Important

Cardboard thickness directly influences the performance, cost, and practicality of packaging in nearly every industry. Here’s why it matters:

- Structural Integrity

Thicker boards—especially those with multiple flutes—offer better resistance to compression, stacking pressure, and mechanical damage. This is essential for products shipped over long distances or stored in high-stacking environments. - Protection During Transit

The thickness helps absorb shock and vibration during transport. Fragile or high-value items often require thicker, double-wall corrugated packaging for adequate cushioning. - Compatibility with Machinery

Folding, die-cutting, and gluing machines require consistent board thickness to operate correctly. Variations in thickness can cause jams, misfeeds, or inaccurate folds. - Print and Branding Quality

For retail or display packaging, thinner boards (like E or F flute) offer smoother surfaces that allow for high-resolution printing, enhancing brand presentation. - Cost-Efficiency

Using thicker cardboard than necessary increases material and shipping costs. Conversely, using cardboard that’s too thin can lead to product damage and customer complaints. Finding the right balance is key. - Sustainability and Waste Reduction

Selecting the optimal thickness ensures you’re not over-packaging. This reduces material waste and supports sustainability initiatives—an increasing priority for global brands and regulators.

Choosing the Right Thickness

When selecting cardboard, consider the following:

Product Weight

- Lightweight items (<1 kg): E or F Flute

- Medium products (1–5 kg): B or C Flute

- Heavy items (>5 kg): Double wall (BC, AC)

Packaging Type

- Folding carton: 0.5 – 1.0 mm solid board

- Shipping box: 3 – 7 mm corrugated

- Retail packaging: 1.5 mm E Flute with print-ready liner

Machinery Compatibility

- Ensure compatibility with your folder gluer, die-cutter, or laminator.

- Many machines accept board thickness from 0.5 mm to 7 mm; consult the specs.

Frequently Asked Questions (FAQs)

How thick is standard corrugated cardboard?

C Flute single-wall board is approximately 3.6 mm thick—considered a standard for shipping boxes.

What GSM is common for cardboard packaging?

Corrugated liners range from 120–250 GSM per layer. Solid board cartons: 250–450 GSM.

Is thicker cardboard always stronger?

Not necessarily. Flute structure, material quality, and ECT rating matter more than thickness alone.

Can cardboard thickness affect print quality?

Yes. Thinner boards like E/F Flute or paperboard allow sharper printing and better folding.

Final Thoughts

Cardboard thickness is more than just a number—it’s a combination of structural design, material density, and functional application. Whether you’re in logistics, printing, or manufacturing, choosing the right cardboard grade ensures better protection, improved efficiency, and reduced waste.

If you need machines that support a wide range of cardboard types and thicknesses, visit Jeytop.com for high-performance folder gluer and box making equipment tailored to industrial needs.