Why Your Printing Quality Problems Are Often Misdiagnosed as Ink Issues

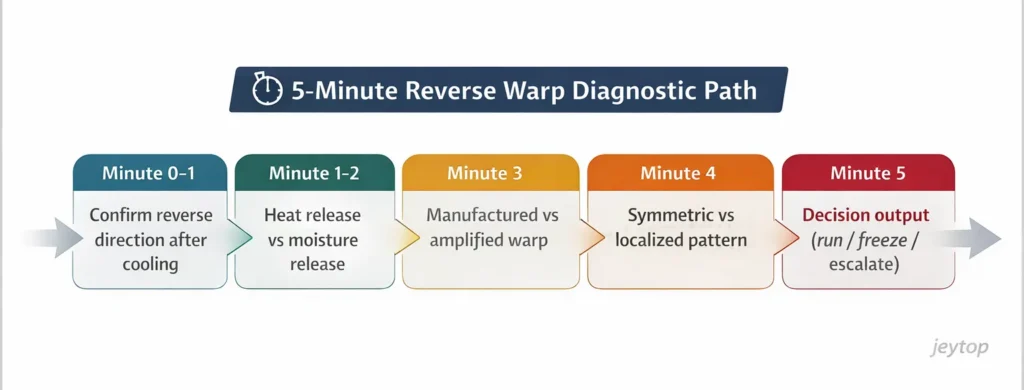

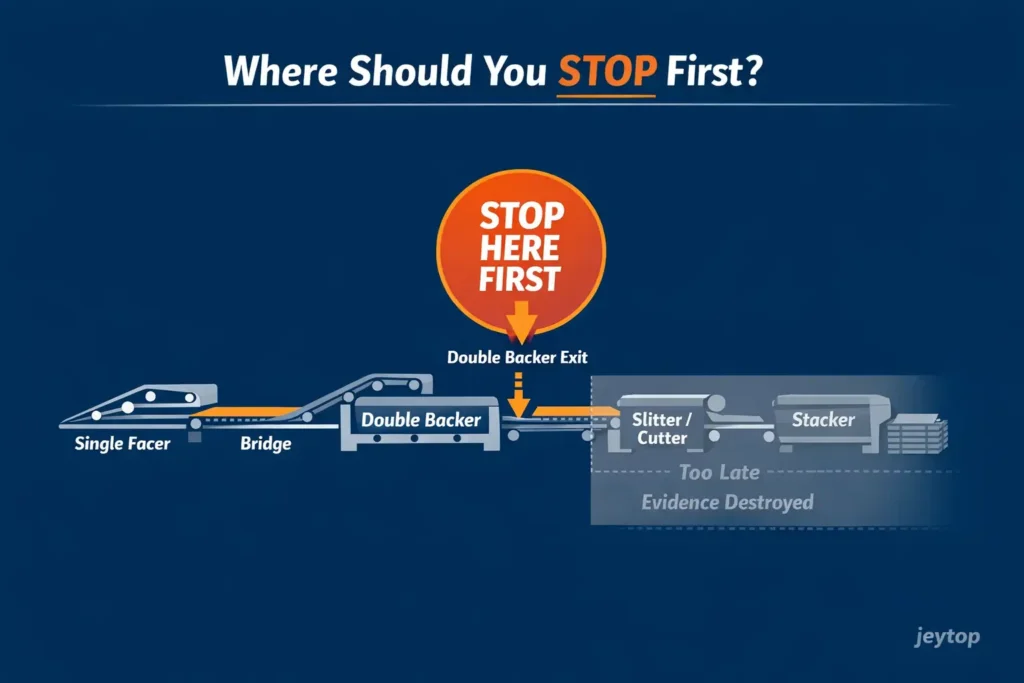

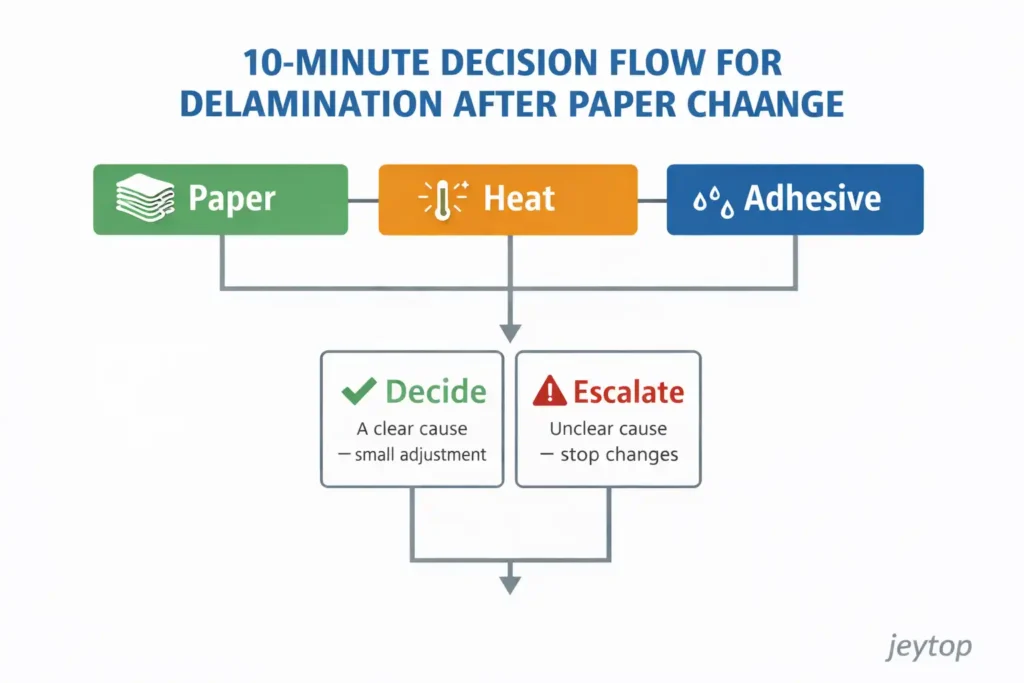

Printing defects are often blamed on ink — but in many corrugated packaging plants, ink is rarely the true root cause. This technical insight explains why misdiagnosis happens so frequently and how printing pressure, substrate behavior, drying performance, and environmental variables can create defects that closely resemble ink failures. Through practical examples and a five-minute diagnostic framework, the article helps production teams quickly distinguish between material issues and system-level problems, reduce downtime, avoid unnecessary supplier disputes, and restore stable printing performance with faster, more accurate troubleshooting decisions.

Why Your Printing Quality Problems Are Often Misdiagnosed as Ink Issues Read More »