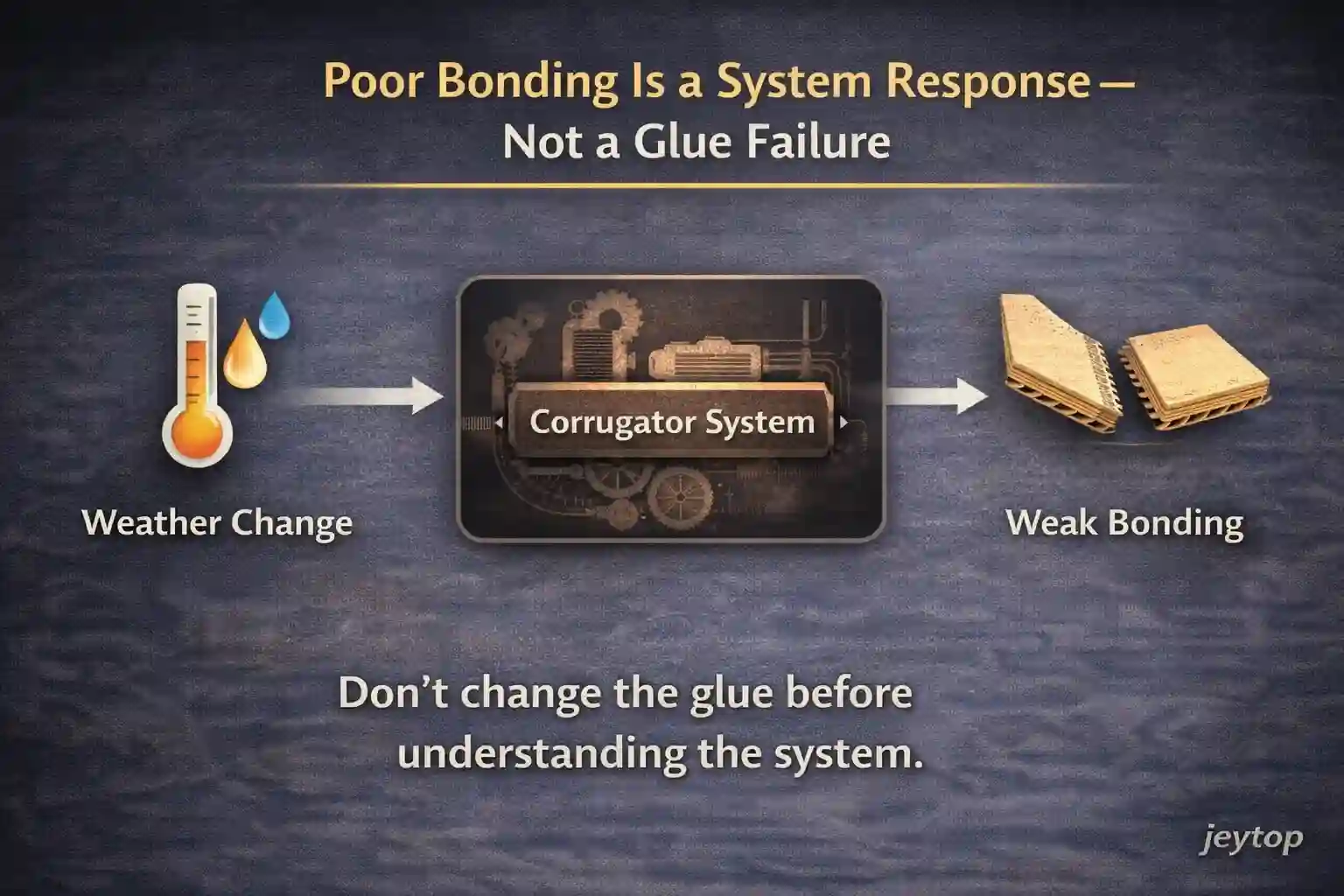

If your corrugator starts showing weak bonding, delamination, or reduced peel strength immediately after a sudden change in weather—higher humidity, lower temperature, or rapid pressure shifts—pause before reaching for the glue formula or glue settings.

What you are facing is rarely a case of adhesive failure.

It is far more often a system-level imbalance triggered by an external variable you do not control: the weather.

Changing glue too early is usually the highest-risk and highest-cost first reaction.

Glue is an execution variable.

Weather is a powerful external input.

When the input changes abruptly, the first task is not to replace the executor—but to understand how the system is responding.

Step One: Identify What Kind of Bond Failure You’re Seeing

Before acting, take one minute to observe the failure pattern. This determines where the imbalance likely sits.

- Weak initial bond

Boards separate easily right after leaving the double backer. - Delayed failure

Bonding appears acceptable at the exit, but separation occurs during stacking, cooling, or short-term storage. - Localized failure

Good bonding on edges but failure in the center—or the opposite.

Key insight:

Different failure modes point to different breakdown points in the system.(Related reading: How flute collapse and bonding failures signal different system-level imbalances)

Initial bond weakness often involves heat timing.

Delayed failure usually involves curing and moisture migration.

Localized failure suggests uneven pressure or drying—not glue chemistry.

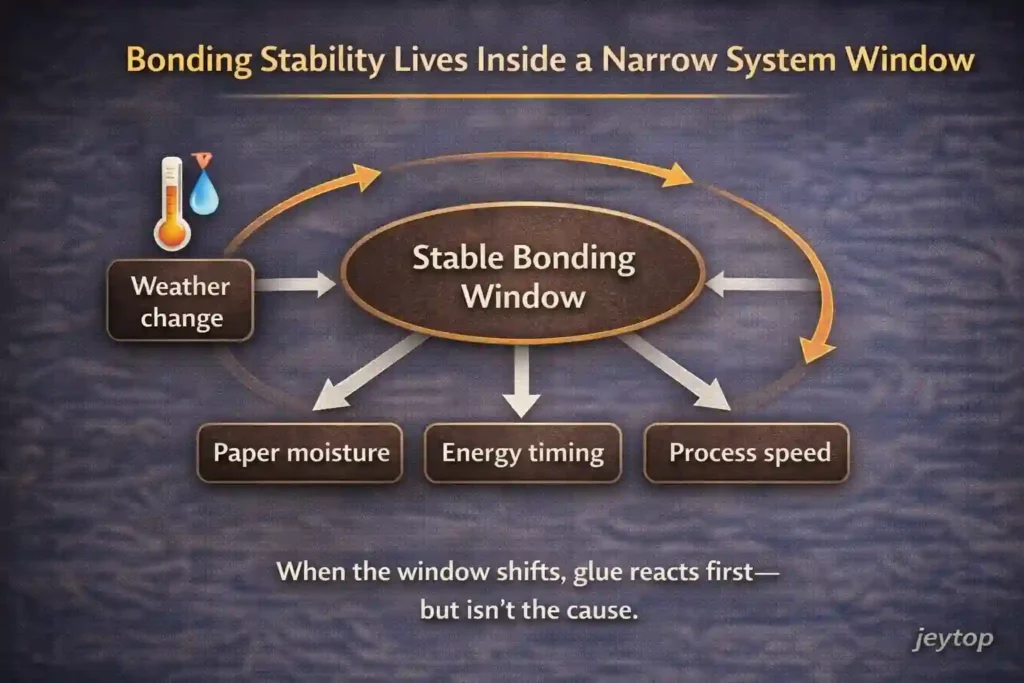

Step Two: What Weather Actually Changes — A System View

Weather is not just a number on a humidity or temperature gauge.

It simultaneously disrupts the balance between paper, heat, glue, and water.

1. Hidden Changes in Paper Condition (Often Overlooked)

- Moisture content:

High humidity increases incoming paper moisture—especially in medium—and accelerates moisture absorption during production. - Starting temperature:

Cold weather lowers paper roll temperature, increasing the energy required to reach reaction thresholds. - Result:

The adhesive’s designed working window shifts or narrows. More water must be handled, or reaction timing is delayed.

2. Heat Being Redirected Away from Bonding

- Increased heat loss:

Colder environments pull energy out of the system faster. - Heat misuse:

In humid conditions, energy is consumed evaporating excess moisture instead of driving starch gelatinization and curing. - Result:

Adhesive does not receive sufficient, focused energy at the correct moment to complete bonding.

3. Adhesive Behavior Changes — Without the Adhesive “Failing”

- Open time shifts:

Ambient conditions alter evaporation rates on the glue roll. - Reaction timing drifts:

Glue now meets paper at temperatures and moisture levels outside its original design assumptions. - Result:

The adhesive is still performing—but the system no longer provides the environment it was designed for.

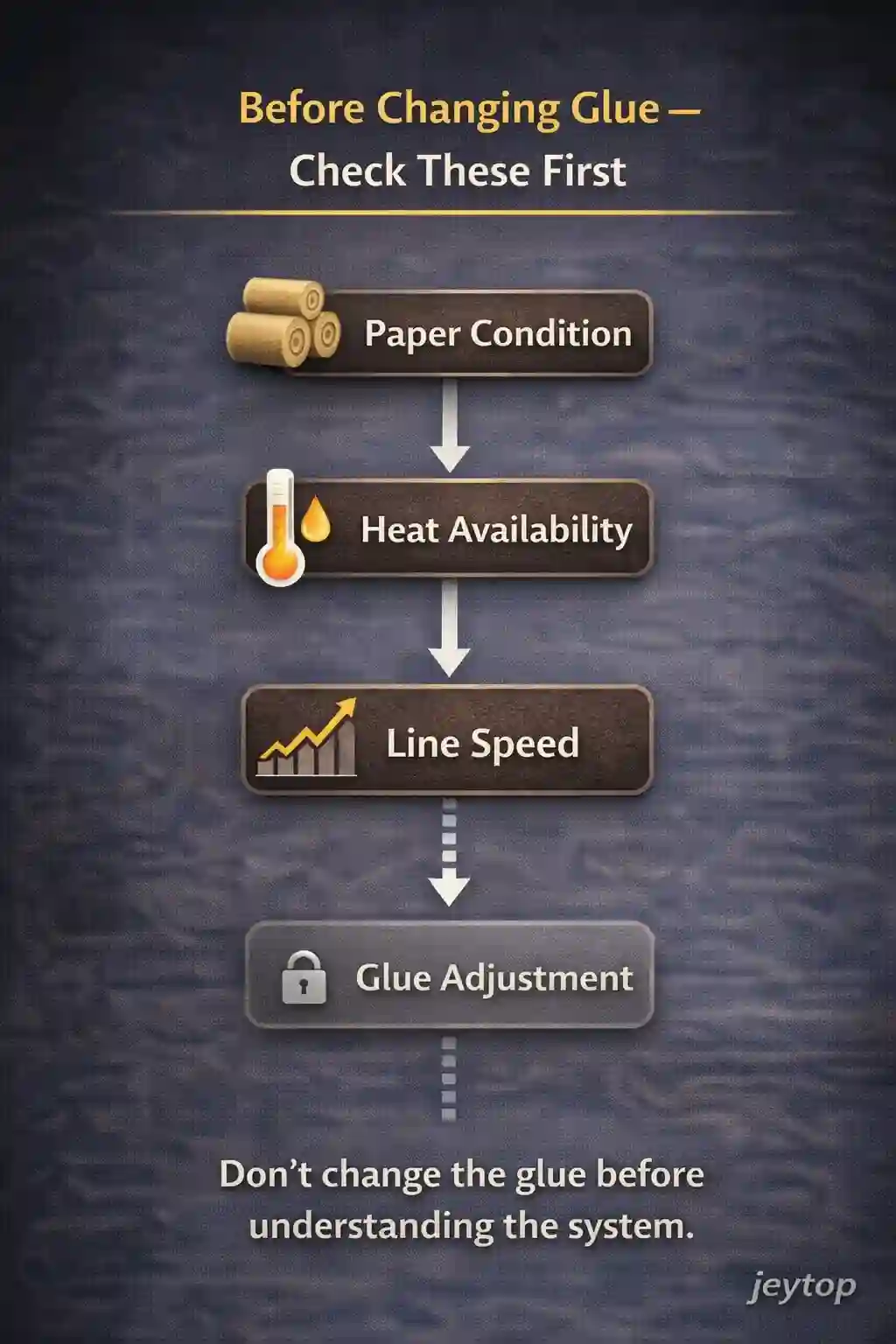

Step Three: Check These Three System Conditions Before Touching the Glue

1. Paper Input — Has the Starting Point Changed?

- Is the current paper batch the first one introduced after the weather shift?

- Does the medium feel noticeably colder or damper by hand?

- Do liner and medium respond differently to touch?

If the input condition changes, every downstream process inherits that shift.

2. Heat — Is It Doing the Right Work?

- Is preheating struggling to establish a meaningful temperature gap between paper and adhesive gelatinization point?

- Is double backer energy being consumed compensating for environmental loss rather than curing the bond?

- Is internal board temperature sufficient—not just surface temperature?

Glue does not need more heat.

It needs the right heat, at the right time, for the right duration.

3. Speed — Is It Amplifying the Weather Effect?

- Does the current speed reduce dwell time in critical temperature zones under new conditions?

- Is line speed turning a small environmental shift into a large process deviation?

Speed is not the cause—but it is a powerful multiplier.

Step Four: Situations Where Glue Must NOT Be Adjusted First

Avoid these instinctive reactions before system conditions are understood:

- ❌ Immediately changing glue formulation or additives

- ❌ Aggressively increasing or decreasing glue application to “force” bonding

- ❌ Using adhesive to compensate for insufficient heat or unfavorable paper condition

Core rule:

Adhesive is one of the most honest responders in the system.

When balance is lost, it shows symptoms early—and is often blamed incorrectly.

The Decision That Actually Matters

At this stage, the goal is not to decide how to change the glue.

You must answer a higher-level question:

Is this bonding failure caused by glue incompatibility—or has the weather shift pushed the entire system outside the adhesive’s workable window?

That answer determines the correct path:

- Minor system adjustment

- Temporary pause and system rebalancing

- Adhesive evaluation only after system conditions are stabilized

Final Takeaway

Weather is an uncontrollable variable.

How you interpret and manage its impact on the system is not.

Production maturity is not defined by how fast glue is changed when bonding fails—

but by how quickly the system is reassessed when the first bad board appears.

The right question is never “What glue should we switch to?”

It is:

“Is our system still providing the conditions this glue needs to succeed?”