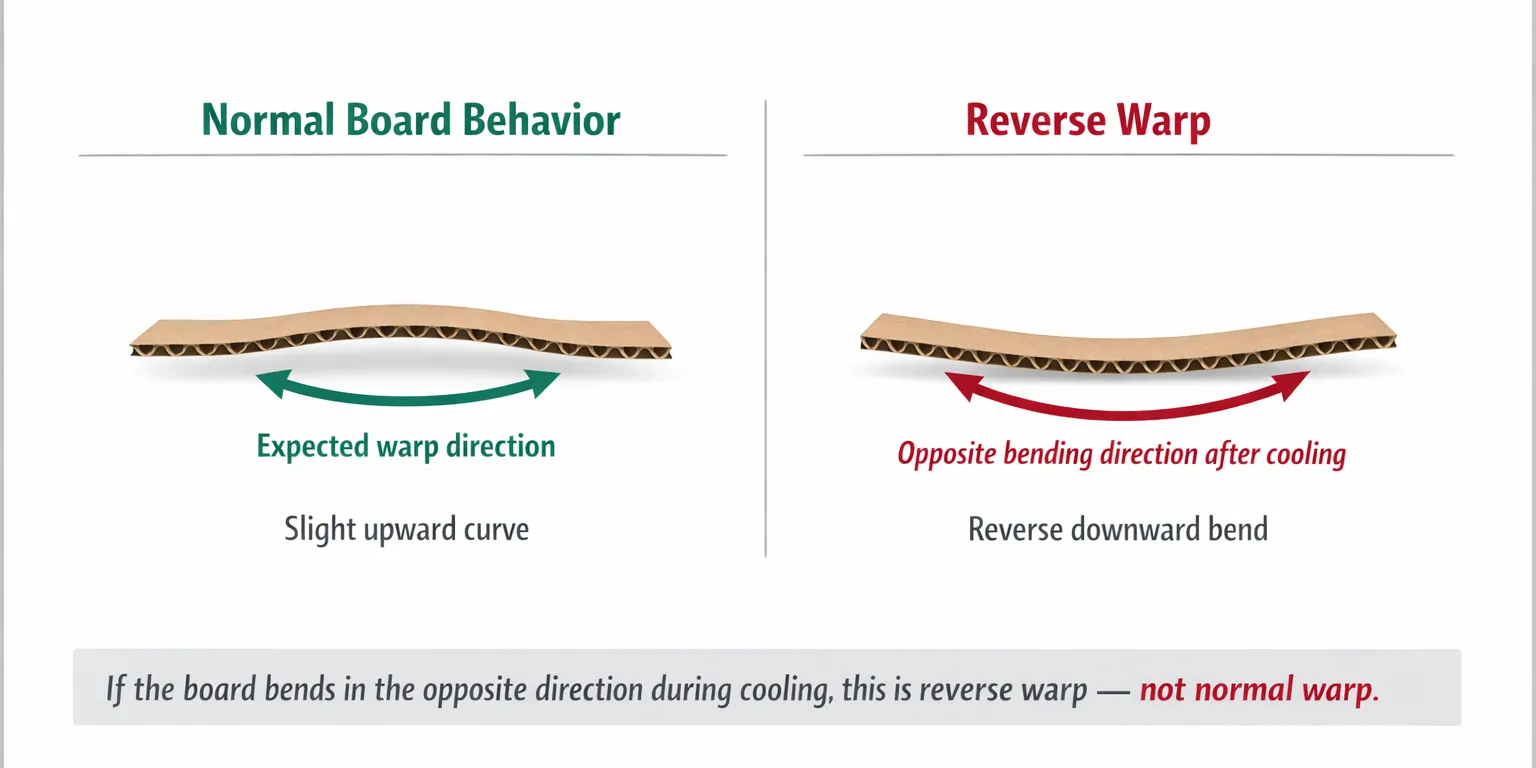

If you notice that boards leaving the double backer or hot plate section begin to bend in the opposite direction during cooling, you are likely not dealing with ordinary warp.

This is a reverse warp—fundamentally different from warp that is already fixed the moment the board exits the hot section (the issue discussed in our other article).

A simple way to understand this is the following:

It is like a brick that comes out of the mold straight, but twists during curing.

The problem lies in the “curing” phase (cooling and stress release)—not in the instant of forming.

Before you begin any judgment, confirm the following visual benchmarks:

- The board appears basically flat at the double backer exit or immediately after the hot plates

- As cooling progresses, the bending direction becomes opposite to what is normally expected

(for example, a board that would normally crown slightly upward now bends downward) - The phenomenon appears across the full width or most of the sheet

If all three apply, you are facing a system signal of incorrect stress release during cooling.

This is not the moment to find answers—it is the moment to decide whether the line can continue running.If a clear decision cannot be made, stopping at the correct point becomes critical.

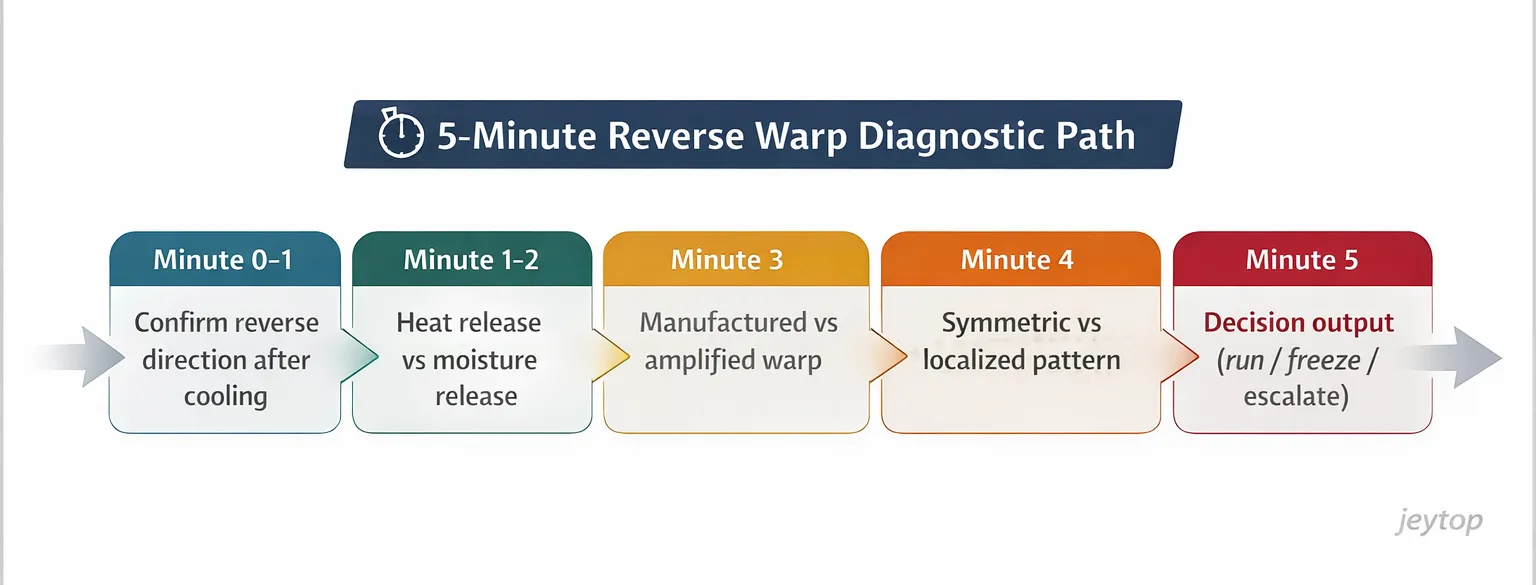

Immediately begin the following 5-minute judgment process. The goal is to identify the nature of the problem, not to make adjustments.

Minute 1–2: The Core Split — Heat Release Error or Moisture Release Error?

Without adjusting any parameters, begin by using touch and observation to make an initial classification.

1. Touch and condition check (right after the hot section):

- Quickly feel the board surface and edges. Does it feel dry or hot on the outside, but cool or damp inside?

- Apply light pressure. Does the board show slow rebound or poor resilience?

- (Optional verification) If available, use an infrared thermometer to compare surface and edge temperatures.

A significant temperature difference (e.g., >10 °C) can support your judgment.

2. Timing and progression:

- Does the reverse warp appear immediately upon exiting the hot section, or

- Does it become more pronounced as cooling continues?

Quick classification direction:

- Dry/hot feel, poor rebound, rapid appearance → more likely a heat release error

(layer shrinkage rates are mismatched) - Cool/damp feel, warp intensifies during cooling → more likely a moisture release error

(consider liner moisture levels and preheater matching)

This step only determines where to look next. It is not a final conclusion.Industry sources note that warp and twist behavior in corrugated board is influenced by moisture and temperature variation, which can be critical when diagnosing reverse warp.

Minute 3: Determine — Was the Warp “Created” or “Amplified”?

Next, determine whether the reverse warp was actively created by operation, or whether it simply revealed an existing imbalance.

Ask yourself:

- In the hot section, was abnormally high pressure used to force the board flat, creating a temporary appearance of correctness?

- After leaving the pressure zone, did the board show clear shape rebound in the opposite direction of the applied force?

Quick logic:

- “Created” reverse warp: External force temporarily suppressed internal stress, which rebounded during cooling

- “Amplified” reverse warp: Pre-existing imbalance was modest, but cooling fully exposed and magnified it

This distinction helps determine whether the issue is more likely rooted in the current process condition or in raw material or base matching factors.

Minute 4: Check Symmetry — System Error or Localized Loss of Control?

Observe the distribution pattern:

- Is the reverse warp left–right symmetrical and uniform across the width?

- Do all paper layers (liners and medium) behave similarly?

What this tells you:

- Symmetrical, uniform reverse warp strongly indicates a system-level process error

(such as oven temperature profile or line speed) - One-sided or localized reverse warp may point to a single preheater, localized roll condition, or paper roll variation

Note: This is still reverse warp logic—not simple one-sided warp.

Minute 5: Emergency Risk Control — The Most Dangerous Misoperation Window

Before the cause is clear, the following actions are strictly prohibited. They almost always increase losses:

- ❌ Attempting to “press out” reverse warp with additional heat

— This increases internal stress differences and hardens the problem - ❌ Extending cooling time to “let it set”

— This may permanently lock in the wrong stress direction - ❌ Repeated speed changes to search for a “sweet spot”

— This destroys the baseline condition needed for reliable judgment

Remember:

Reverse warp is not a lack of setting—it is setting in the wrong direction.

Any form of reprocessing risks turning a reversible process issue into an irreversible, batch-level quality failure.

After 5 Minutes: Your Only Required Output

Time is up. You do not need to know what to adjust.

You must be able to state one clear directional conclusion:

“This reverse warp most likely originates from:

① incorrect heat release sequence /

② incorrect moisture migration direction /

③ pressure in the hot section masking inherent stress.”

That conclusion determines the next step:

- Can the line continue running cautiously?

- Must the line be stopped and conditions frozen?

- Should the issue be escalated to process or quality engineering?

One final sentence to remember:

Reverse warp is not corrected by “tuning parameters.”

It is the system’s final verdict during cooling on whether heat, moisture, pressure, and time were truly coordinated.

Your value lies in understanding that verdict within the first five minutes.