When delamination starts immediately after a paper roll change, the production floor often turns tense.

Quality questions the paper. Purchasing questions the process. Operators start adjusting parameters.

In the first ten minutes, the real danger is not choosing the wrong side —

it is rushing to a conclusion without a clear diagnostic path.

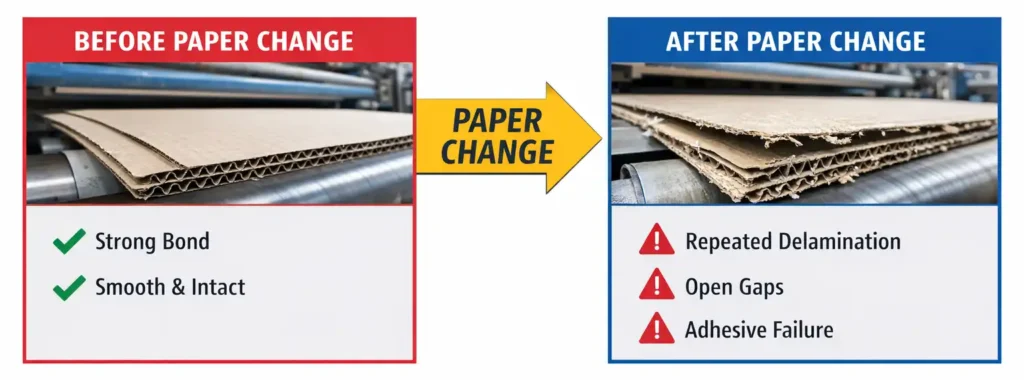

Continuous delamination after a paper change almost always indicates that an existing process balance has been broken.

The goal is not to assign responsibility, but to determine where the mismatch is coming from — paper, heat, or system interaction — before blind adjustments create scrap, downtime, or downstream risk.

What qualifies as “continuous delamination after a paper change”?

This article addresses a very specific situation:

This applies if:

- Delamination appears shortly after a paper roll change (typically within the first hour).

- Line speed, temperatures, and adhesive formulation were not intentionally changed.

- The failure pattern is repetitive (same liner, same side, same zone).

This does not apply if:

- The issue is a single, isolated event.

- The same paper shows long-term, stable delamination problems.

- There is an obvious mechanical fault such as glue interruption or blocked applicators.

The focus here is material-triggered system imbalance, not chronic equipment issues.

A critical mindset correction

When delamination follows a paper change, paper and process factors usually coexist.

The new paper may have different:

- Moisture absorption behavior

- Surface sizing

- Incoming temperature

Meanwhile, the corrugator is still running under parameters optimized for the previous paper.

This is a classic case of system imbalance, similar to what happens when one-way warp suddenly appears after a process disturbance.(Sudden One-Way Warp in Corrugated Board? Don’t Touch the Speed—Check These Three Things First)

The old balance no longer exists.

A new balance has not yet been established.

Understanding this prevents the most common mistake: arguing about responsibility instead of restoring compatibility.

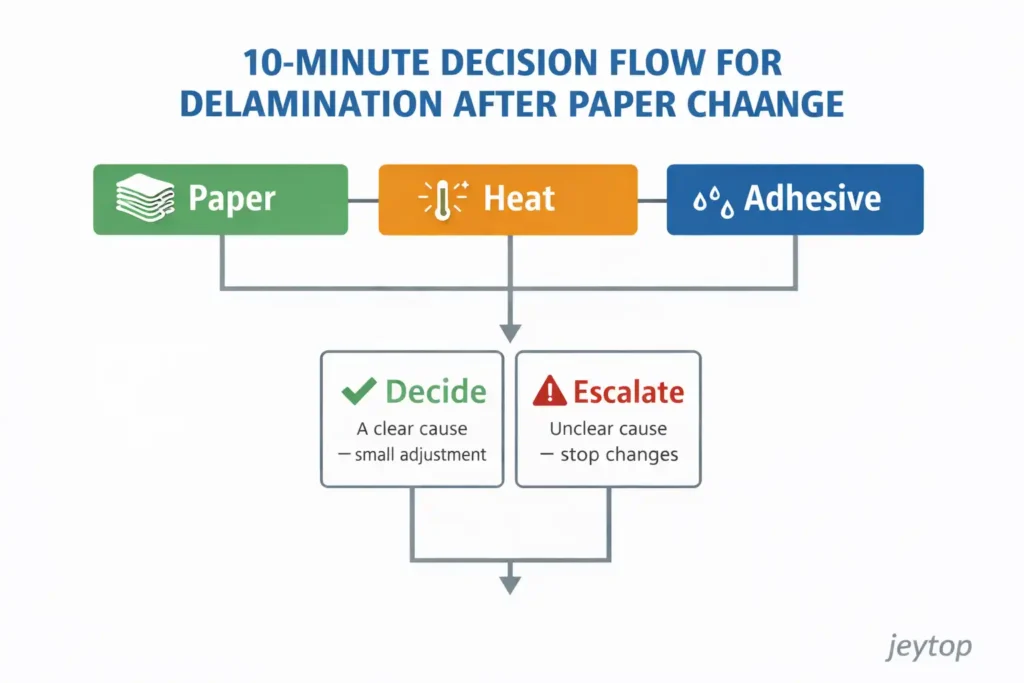

The 10-minute diagnostic sequence (follow the order strictly)

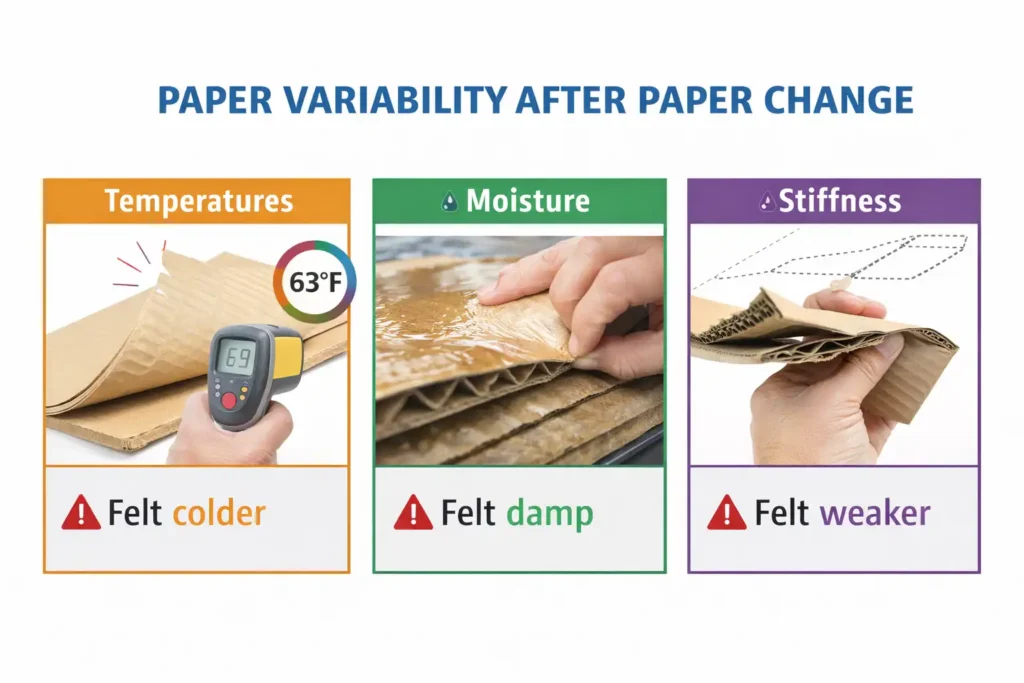

Paper condition: has the input changed?

The goal is not to judge paper quality, but to confirm whether it deviates from the previous baseline.

- Compare stiffness by bending new paper against a scrap of the previous paper.

- Lightly scratch the surface to compare fiber lifting or fuzzing.

- At the preheater exit, scan the web by hand for cool, damp, or “dead” zones.

- Watch for visual cues such as abnormal grayness, dusting, or localized wet spots.

If the physical behavior has changed, existing settings may no longer be adequate — but this is confirmation, not a verdict.

Heat matching: is the process still aligned with this paper?

Paper changes often expose heat mismatch rather than create adhesive problems.

- Check the singleface entering the double backer. Is it noticeably drier or more brittle than usual?

- Observe the board in the middle hot-plate section. Premature whitening combined with low exit toughness often signals surface over-drying without proper internal bonding.

- If paper behavior changes but the heating profile does not, imbalance is unavoidable.

Adhesive behavior: is glue being forced to take the blame?

Adhesive is rarely the first failure point after a paper change.This cause-and-effect sequence — where paper characteristics and heat transfer are evaluated before adhesive adjustments — is consistent with the TAPPI corrugator bonding troubleshooting guide.

- Note whether delamination concentrates on a specific liner or side.

- Gently peel the failure area:

- Smooth surface with little fiber pull suggests insufficient penetration or gelatinization.

- Heavy fiber tear points toward paper surface strength limitations.

- If bonding appears acceptable under heat but fails after cooling, false bonding is likely involved.

At this stage, many operators are misled by boards that look bonded at the hot plate exit but fail later during cooling or stacking.

This delayed failure mechanism is explained in detail in our article:

(When the Board “Looks Bonded” After the Double Backer—Don’t Be Misled, Check These Three Things First)

Adjusting adhesive before paper and heat are understood almost always leads to misdiagnosis.

Before the cause is clear, avoid these actions

- Do not immediately switch back to the old paper.

It hides the real compatibility issue and guarantees recurrence. - Do not make large adhesive formulation changes.

Adhesive behavior is often a result, not the root cause.

Similar mistakes happen when operators slow down the line first during sudden delamination or warp events.( Single-Side Delamination on a Corrugator Line — Why Slowing Down First Makes Things Worse) - Do not adjust multiple parameters simultaneously.

Each blind adjustment destroys the process baseline and eliminates traceability.

The decision point

If you can explain a clear cause-and-effect chain —

for example, increased moisture absorption leading to singleface over-drying — make one small, targeted adjustment and observe trends for 15–20 minutes.

If no clear technical consensus exists, stop further changes, roll back non-essential adjustments, mark affected production, document observations, and escalate jointly to process and quality teams.

Continuing without clarity does not reduce risk.

It moves it downstream.

Final perspective

Continuous delamination after a paper change is not a quality accident.

It is the corrugator system signaling that an old balance has failed and a new one must be built.

Stable operations are not defined by the absence of problems, but by the ability to diagnose systematically, restore balance calmly, and protect downstream quality under pressure.