When corrugated board on the line suddenly starts warping hard in one direction, what is your first reaction?

This kind of sudden one-way warp in corrugated board is rarely caused by speed itself.

If the answer is “let’s adjust the speed and see,” then in about 90% of cases, the first move on the floor is already wrong.

Speed is an amplifier, not a fixer.This same “speed-first” mistake is also the root cause behind sudden single-side delamination on corrugator lines.

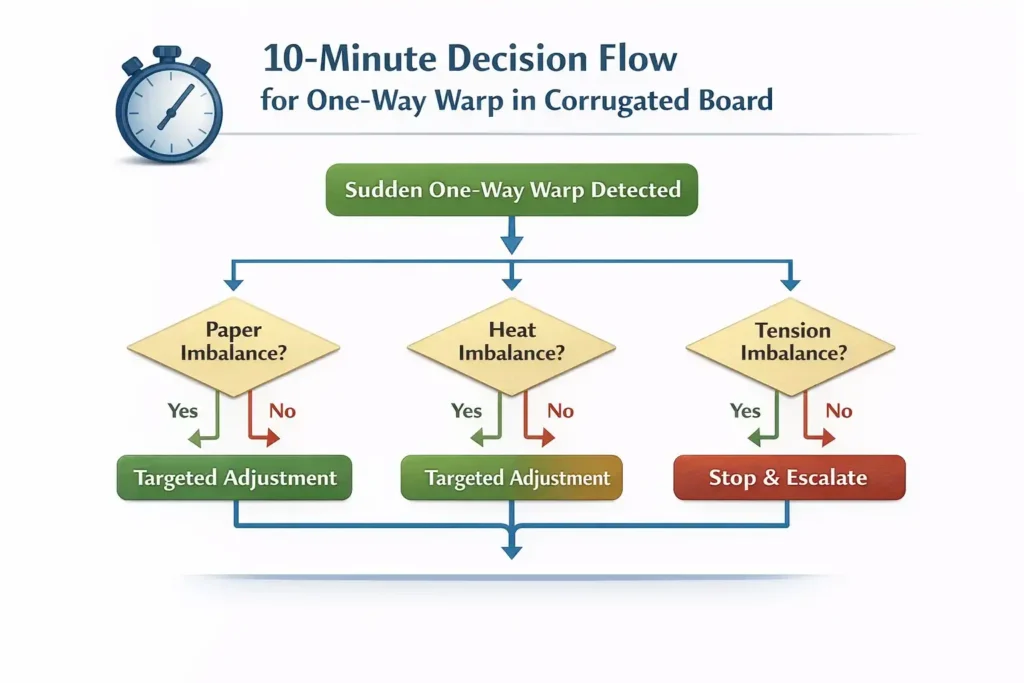

A sudden one-way warp means the balance somewhere in the line has already been broken. This article is a 10-minute on-line decision checklist to help you quickly pinpoint the real cause—paper, heat, or mechanical imbalance—before ineffective adjustments hide the problem and turn it into scrap, downtime, or customer complaints.

Quick Confirmation: Is This a Sudden One-Way Warp in Corrugated Board? (1 Minute)

Before touching any controls, confirm whether your situation fits this checklist.

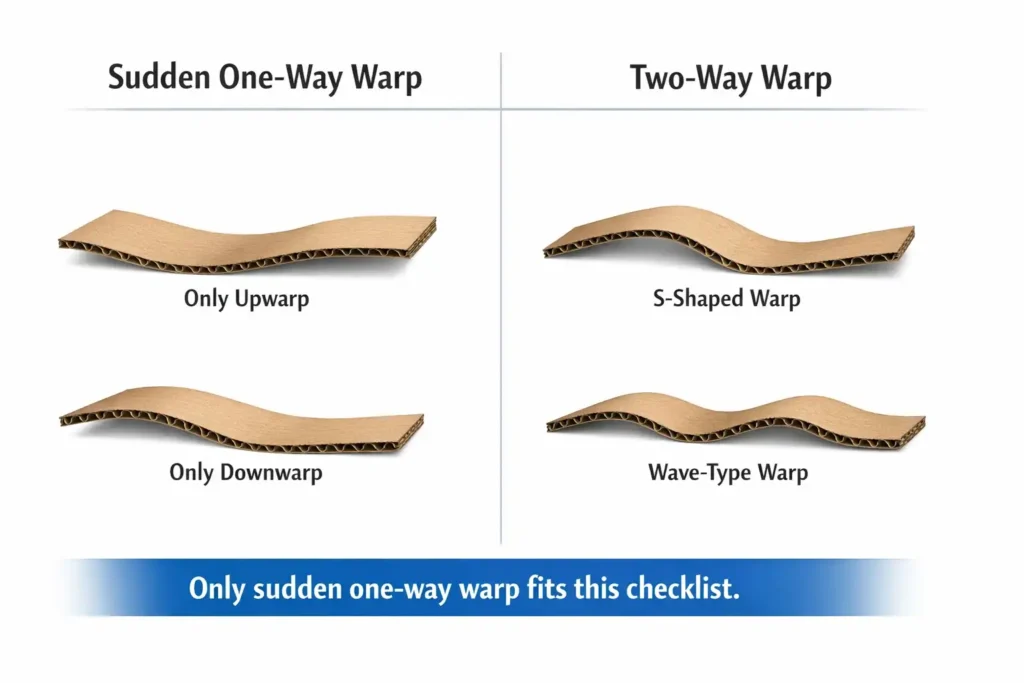

✅ This checklist applies if:

- The warp direction is clear and consistent (only upwarp, only downwarp, or clearly biased to one side).

- The condition worsened suddenly compared with the previous shift or the previous paper roll.

❌ This checklist does NOT apply if:

- The board shows S-shaped or wave-type two-direction warp.

- The warp has existed for a long time and changes gradually.

- The deformation appears mainly after stacking or storage.

One purpose only:

Do not confuse a sudden loss of balance with a long-term process issue. The logic for handling them is completely different.

Why Speed Adjustment Fails When One-Way Warp Occurs in Corrugated Board

One-way warp in corrugated board is a physical imbalance problem, not a speed problem.

When one-way warp occurs, adjusting line speed does not correct the underlying imbalance—it often makes it worse.

Because one-way warp is fundamentally a loss of physical balance between two sides or two layers of the board.

As defined by TAPPI TIP 0304-07, warp in corrugated board occurs due to moisture, heat, and tension imbalances across the board layers.

It usually comes down to one of three things:

- Moisture or temperature imbalance (one side is wetter or colder)

- Uneven heat input (one side or one section is overheated)

- Uneven force (one side is pulled tighter or pressed lighter)

Changing speed does not correct these imbalances.

Adjusting speed after the system is already unbalanced is like making a person with a limp run faster or slower—the limp does not disappear; only the timing of the fall changes.

The Three Imbalance Points That Cause One-Way Warp in Corrugated Board

Do not change the order.

Start with what is most common and easiest to verify.

1. Primary Suspect: Sudden Imbalance in Paper Moisture or Temperature

Why first:

More than 80% of sudden one-way warp originates from the paper itself. Local moisture pickup or cooling of liner or medium is the most common trigger.

Quick on-line checks:

- Touch comparison: After the preheaters, quickly touch both sides of the paper. Does one side feel noticeably cooler, damper, or softer?

- Instrument check: Scan with an infrared thermometer. A side-to-side temperature difference greater than 5°C indicates a significant imbalance.

- Review recent changes: Was a new paper roll just loaded? Did day–night temperature swings cause condensation in the plant? Could condensate be dripping from steam lines onto the paper?

2. Second Suspect: Heat Input Imbalance (Side-to-Side or Front-to-Back)

Why it matters:

Uneven heating causes asymmetric shrinkage. Local overheating or over-drying in one section will physically pull the board toward one side.

How to judge on the floor:

- Observe direction: Does the warp consistently bend toward the drive side or operator side?

- Check hot plates: Compare steam pressure readings across sections. During downtime, feel for uneven surface temperatures.

- Common trap: Slowing the line to “dry more” often amplifies existing drying differences instead of correcting them.

3. Third Suspect: Tension or Pressure Balance Has Been Disturbed

Typical scenario:

This often follows small local adjustments—edge guides, cooling section pull-roll pressure, or bridge tension settings.

Key checks:

- Does the warp consistently bend toward the drive side, where tension is usually higher?

- Are relevant rolls parallel, and is air pressure balanced left to right?

- Do bridge tension settings between the single facer and double backer actually match current conditions?

Before the Cause Is Clear, Do NOT Do These Three Things

- ❌ Do not adjust speed first

It hides diagnostic signals and creates the illusion of improvement while the problem is only postponed. - ❌ Do not immediately change or add adhesive

Adhesive affects bond strength, not geometric deformation caused by physical imbalance. - ❌ Do not adjust multiple parameters “by experience”

Multiple simultaneous changes destroy the process baseline and make the issue impossible to trace.

A similar misjudgment happens when boards “look bonded” after the double backer but fail later.

Core rule:

Diagnose first, intervene second. Anything else is gambling.

The 10-Minute Decision Point: Act or Escalate

Case A: You can clearly explain the cause

Example:

“The drive-side liner is colder, causing uneven shrinkage,” or “Steam pressure is low in hot plate section three.”

Correct action:

Make a single, small, targeted adjustment (for example, slightly adjust the preheater wrap angle or steam pressure on that side). Then observe trends for at least 10–15 minutes. Aim for stability, not instant flatness.

Case B: You cannot explain it—only a feeling

Example:

“The paper feels bad,” or “something just seems off.”

Correct action:

Stop all further adjustments immediately. Roll back the most recent non-essential changes. Mark the affected production, document the symptoms, and escalate to a process engineer for deeper analysis.

Continuing to adjust without clear cause-and-effect is how untraceable production incidents are created.

Final Note

In practice, one-way warp in corrugated board is rarely a single-parameter issue—it is always the result of an unresolved physical imbalance.

Warp itself is not dangerous—it is the production line talking to you.

The real danger is trying to silence it with speed adjustments after imbalance has already occurred.

Stable production does not mean problems never happen.

It means that when problems strike, you still follow the correct decision order: find the source of imbalance first, then restore balance.

That is what it truly means to control a corrugator line.