Subtitle: A practical guide to end production line headaches and achieve predictable, self-stabilizing quality.

As a box plant owner or production manager, you know this all too well. Achieving reliable corrugated moisture control is key to solving these issues:

- Warped boards lead to customer line stoppages, complaints, and lost orders.

- Recurring glue failures silently burn through your liner, medium, and labor hours.

- Unstable strength means your warehouse is stacked with pallets that could collapse at any moment.

You’ve probably tried adjusting the pre-heaters, changing glue recipes… but the problems always come back.

Let’s be direct about the root cause and the solution:

Over 90% of these issues stem from one common source: uncontrolled moisture content in corrugated board. This is not a single-step problem. It’s a systemic issue that runs through the entire process, from raw material (requiring a strict liner moisture standard) and adhesive application to drying. This is the core challenge of corrugated moisture control.

This article will do three things for you:

- Give you a “Diagnostic Map”: Learn to pinpoint exactly where the “moisture” problem is occurring by reading the “symptoms” of warping and de-lamination, just like a seasoned doctor.

- Provide a “Solution Menu”: See the full range of fixes, from quick-fire operator workarounds to the equipment capabilities required for long-term stability.

- Help you calculate the real cost: Understand why investing in equipment that delivers moisture control precision is the most cost-effective and fundamental solution.

We deal in facts, not theory. Let’s start by understanding how moisture content acts like a puppeteer, controlling the quality of your board.

Chapter 1: Understanding the Power of “Water” – How It Sabotages Your Production Floor

To catch the “invisible hand” of moisture content and achieve true corrugated moisture control, we first need to understand its methods on your production line. Mastering this is essential for effective corrugated moisture control.

Don’t worry about complexity. Remember this core analogy: The paper on your production line is like a series of “sponges.”

- A bone-dry sponge is hard and brittle, crumbling under pressure—just like overly dry board, where weak fiber bonding leads to a plummeting Edge Crush Test (ECT) and significant cardboard strength loss.

- A soaking-wet sponge is soft and collapses, losing all form—just like overly wet board, where fibers are “pushed apart” by water molecules, losing rigidity and easily crushing under stack weight.

- Only a perfectly damp sponge is both soft, resilient, and able to bear weight while holding its shape—this is the perfect board state we strive for.

Now, let’s apply this analogy to your three biggest headaches and see how “water” precisely causes damage:

1. 【Warping】 – “The Tug-of-War Inside Your Board”

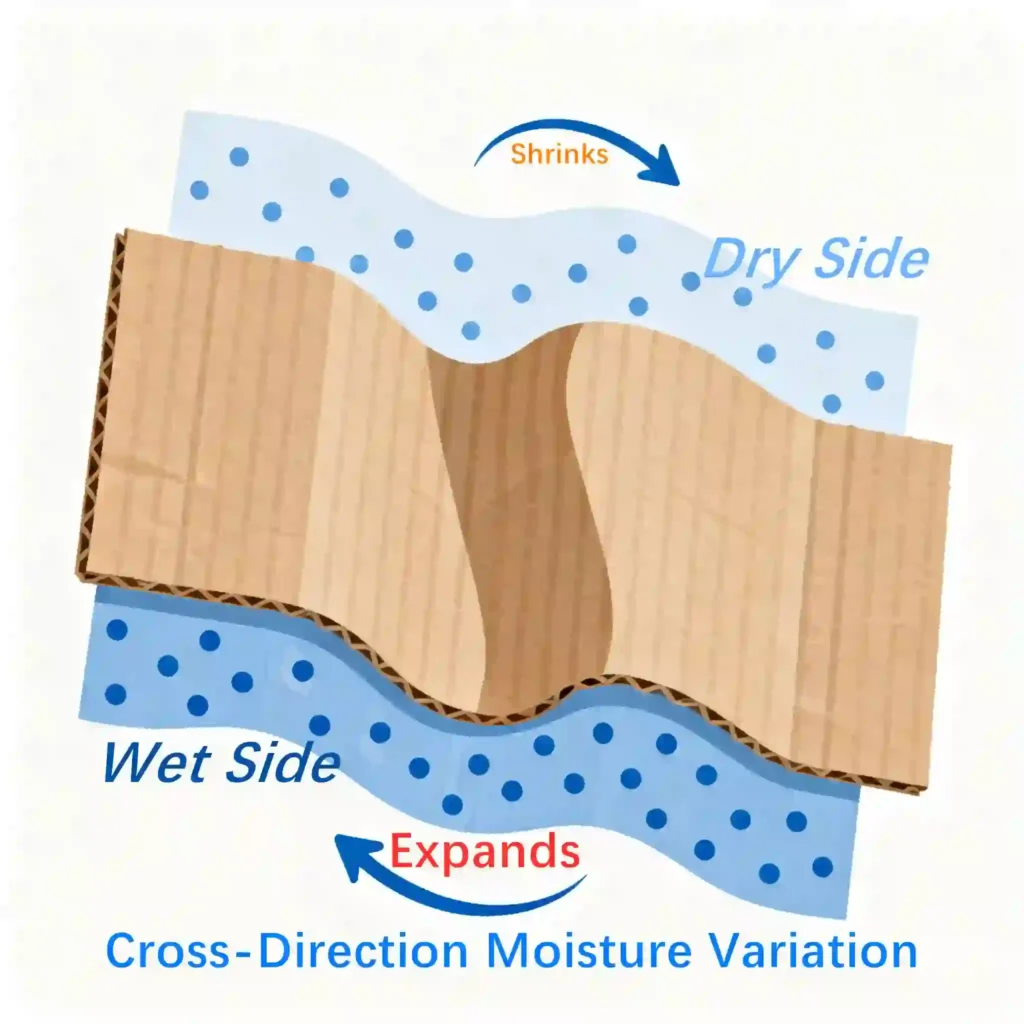

Imagine gluing a dry sponge and a wet sponge together. The wet side wants to expand, the dry side wants to shrink. The two forces pull against each other, and the glued piece bends towards the dry side.

The reality in your plant is this: If your single-face medium and your liner(s) have different moisture content, they engage in exactly this “tug-of-war” after bonding. The side with higher moisture expands, the side with lower moisture contracts. The powerful internal stress literally “pulls” the board into a curve, creating the S-shape, C-shape, or longitudinal warp you see. Understanding this is the first step to finding board warping causes and solutions.

2. 【Glue Failure】 – “The Adhesive’s ‘Futile Work'”

Starch glue needs a precise “working environment” to bond perfectly: it must absorb enough heat to reach its “gelatinization temperature,” turning into a viscous gel that can penetrate the paper and form a strong bond.

- If the paper is too dry (“glue-snatching”): The dry paper fibers act like a desert soaking up water, instantly “snatching” the moisture from the glue. The glue dries out before it can gelatinize, leading to false bonds or outright corrugated glue failure.

- If the paper is too wet (“dilution”): Excess moisture prevents the glue from absorbing enough heat to gelatinize and simultaneously “dilutes” the glue concentration. The result is that the glue cannot form an effective bond, again leading to de-lamination.

3. 【Strength Loss】 – “The ‘Scaffolding’ Softened by Water”

Think of corrugated board’s structure (which we break down in our Corrugated Board Guide) as a construction site scaffold. The upright flutes are the “steel pipes” that carry the load.

When the overall board moisture is too high, these “pipes” (paper fibers) are surrounded and softened by water molecules. Their inherent stiffness drops drastically, and the entire “scaffold’s” load-bearing capacity is compromised, resulting in cardboard strength loss. This is the fundamental reason why lab ECT scores can be acceptable, but damp boxes in warehouse storage can collapse unexpectedly.

Beyond these three core issues, poor corrugated moisture control is also the creator of many “hidden costs” in your plant:

- Printing Defects: Warped boards lead to uneven print pressure, causing blurry text and misregistration; uneven board surfaces with varying moisture absorb ink inconsistently, leading to mottled colors and watermark-like patterns.

- Die-Cutting Inaccuracy: Board dimensions “breathe” (expand and contract) with moisture changes. A die that cuts perfectly today might be misaligned tomorrow due to weather or a new batch of paper, causing misaligned cuts and soaring waste rates.

- Limited Line Speed: To prevent severe glue failure when moisture is unstable, operators often hesitate to run the line at full speed, directly capping your productivity potential.

- Increased Energy Consumption: To “dry out” overly wet board, you are forced to over-rely on the dryer section heating, meaning your steam (energy) costs silently exceed the budget.

Our Core Advice:

While this article focuses on the three most critical problems—warping, glue failure, and strength—you must build a core understanding: Moisture control is not a single process parameter; it is the lifeline that determines the stability, cost-efficiency, and final product quality of your entire production system.

Chapter 2: Board Warping Causes and Solutions: A Practical Diagnostic Room

Now that we understand the theory, let’s get practical. This chapter is your “field guide.” When a problem arises, don’t panic.(For a broader look at common issues, explore our overview on Fixing Corrugated Board Defects) Just follow the symptoms below step-by-step to accurately locate the source of the moisture control failure.

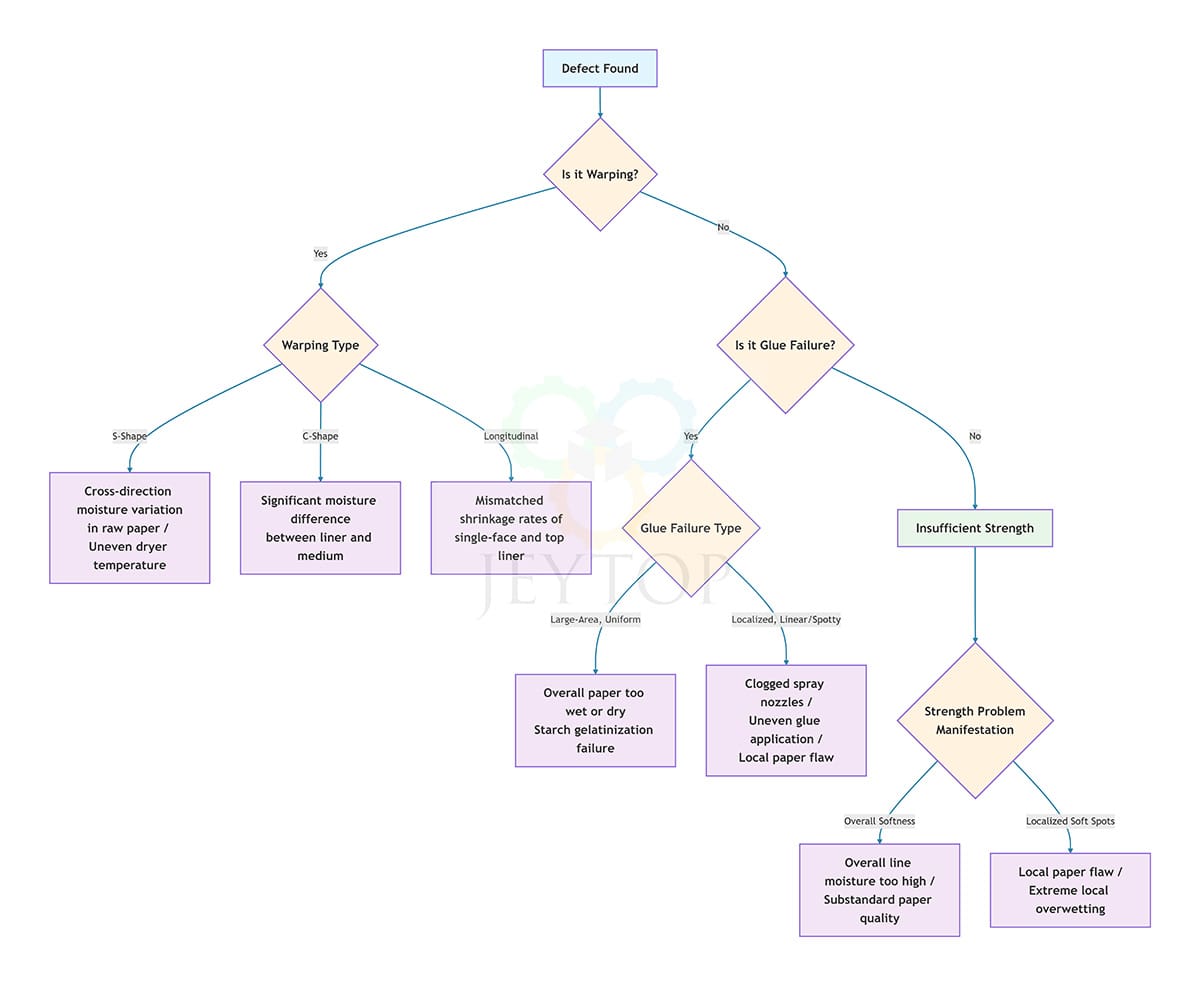

To help you diagnose most efficiently, we’ve created the following 《Quick Diagnostic Flowchart for Moisture-Related Defects》. You can save or print it and post it in your shop for immediate reference.

Flowchart Logic:

- Start: Defect Found

- First Question: Is it Warping?

- Yes -> Proceed to “Warping Type.”

- No -> Next Question: Is it Glue Failure?

- Yes -> Proceed to “Glue Failure Type.”

- No -> Points to “Insufficient Strength or Other Issues.”

- Leads to the “Most Likely Root Cause” based on the specific type.

Below, we break down each decision point in the flowchart, providing clear board warping causes and solutions and linking them directly to failures in corrugated moisture control.

Dealing with Warping? – Identify the Shape, Find the Source

Different warp shapes point to different patterns of moisture imbalance.

- Symptom: S-Shape Warp (board twists like a rope)

- Most Likely Root Cause: Severe cross-direction moisture variation in the raw paper, or uneven surface temperature across the dryer section.

- Plain Explanation: This is like a strip of towel dipped in hot water on one side (expands) and cold water on the other (contracts)—the towel twists. Your paper has one wet side and one dry side across its width, or the dryer has a hot side and a cool side.

- Symptom: C-Shape Warp (board arches in one direction)

- Most Likely Root Cause: Significant moisture content difference between the liner and medium.

- Plain Explanation: This is the classic “tug-of-war” scene from Chapter 1. For example, if the top liner is too wet (wants to expand) and the bottom liner is too dry (wants to shrink), the board will arch globally towards the dry side (the bottom liner).

- Symptom: Longitudinal Warp (warp along machine direction)

- Most Likely Root Cause: The single-face medium and top liner have mismatched shrinkage rates on the double backer.

- Plain Explanation: When passing through the hot plates, the shrinkage of the single-face and the top liner are out of sync. Often, the single-face is already too dry before entering the double backer, having lost its ability to shrink, while the top liner shrinks normally, causing the board to warp towards the single-face side.

Dealing with Corrugated Glue Failure? – Identify the Location, Find the Culprit

- Symptom: Large-Area, Uniform Glue Failure

- Most Likely Root Cause: The raw paper is entirely too wet or too dry, causing starch gelatinization to fail.

- Plain Explanation: This is a systemic breakdown of the “glue working environment.” It’s either a plant-wide “glue-snatching” (paper too dry) or a plant-wide “dilution” (paper too wet).

- Symptom: Localized, Linear, or Spotty Glue Failure

- Most Likely Root Cause: Clogged spray nozzles, uneven glue application, or local flaws in the raw paper.

- Plain Explanation: This is a “local drought or flood.” A specific spray nozzle is clogged, leaving that strip of paper too dry; or the glue roll is damaged, leading to insufficient local glue application.

Dealing with Cardboard Strength Loss? – Feel the Board, Check the Whole

- Symptom: Overall Soft Board, ECT collapses easily

- Most Likely Root Cause: The production line’s overall moisture control is too high, or the raw paper quality itself is substandard.

- Action Guide: First, test the Ring Crush Test (RCT) of the raw paper. If the paper is fine, it’s almost certain your production line is making the board “too wet,” softening the paper fibers.

- Symptom: Localized Soft Spots, uneven feel

- Most Likely Root Cause: Intrinsic flaws in the raw paper (e.g., “slime spots” causing local low basis weight), or extreme local over-wetting during production.

- Action Guide: Focus inspection on raw paper quality and its liner moisture standard.

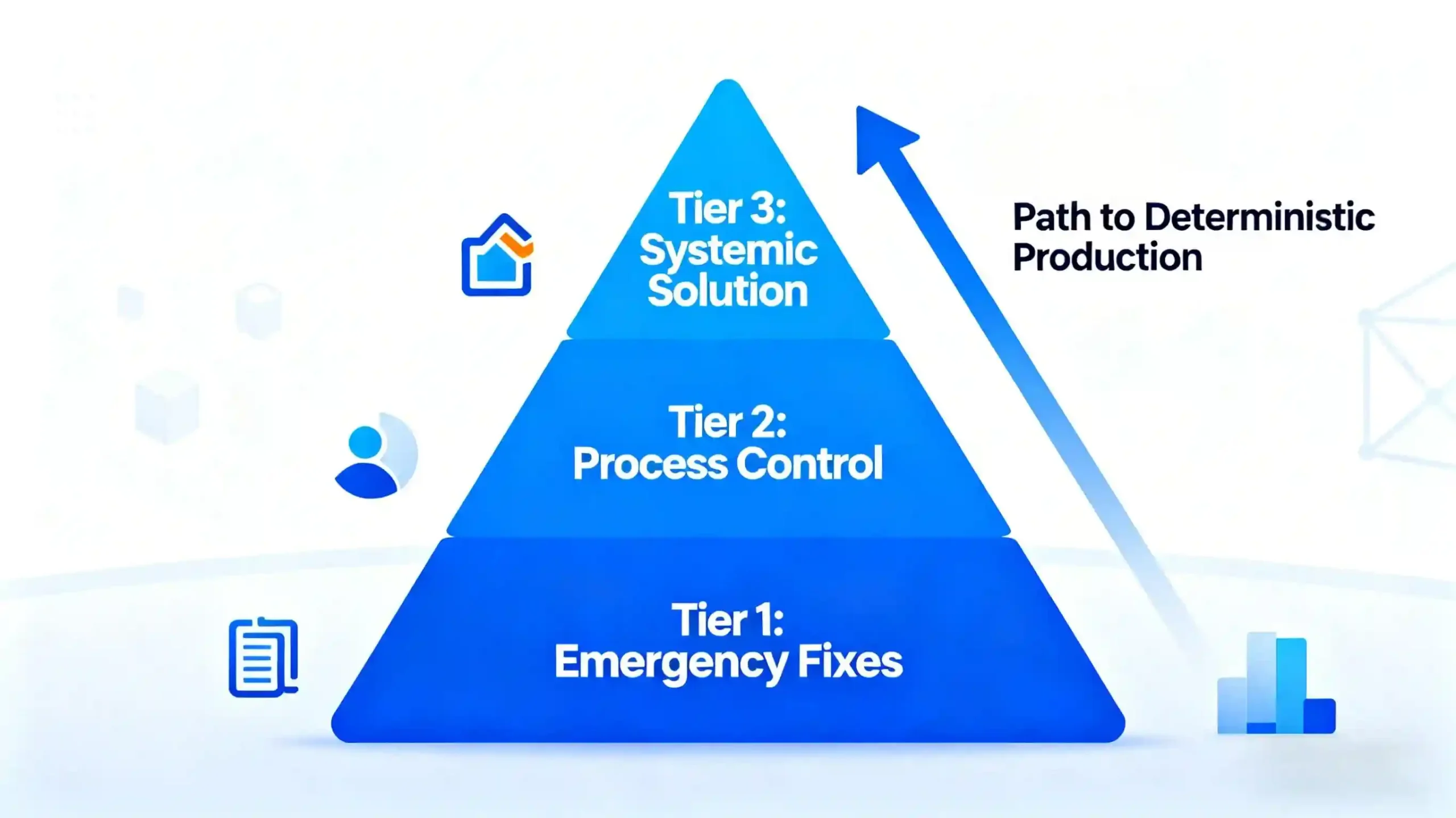

Chapter 3: The Three-Tier Solution Playbook: From Emergency Response to Root Cause Elimination

Now that we’ve diagnosed the problem, it’s time for action. This chapter provides a complete library of solutions, from easy to complex, temporary to permanent. Please find your factory’s situation and use the solutions accordingly. This is the heart of practical corrugated moisture control.

Tier 1: On-the-Spot Emergency Solutions (“The Quick Reaction Force”)

- Goal: Quickly control the situation and restore production when a problem occurs.

- Applicable Scenario: Sudden warping, temporary glue failure; used as an immediately actionable remedy.

| Solution | Concrete Action Steps | Applicable Conditions / Symptoms | Solution Limitations |

| Preheater Adjustment | 1. Observe the warp direction. 2. Increase the preheater wrap angle for the sheet on the side the board is curling towards. 3. Observe the effect for 10-15 minutes after fine-tuning. | Suitable for slight C-shape or longitudinal warping. | Effects are short-lived; it’s a balancing act, not a cure. Over-adjustment can affect glue gelatinization. |

| Targeted Spraying | 1. Identify the dry paper surface. 2. Use a handheld spray device to apply precise, minimal misting to the dry surface. | Applicable for slight warping or glue failure caused by locally overdry paper. | Highly dependent on operator skill. Over-spraying causes other quality issues. |

| Tension/Speed Balancing | 1. Slightly reduce line speed. 2. Appropriately adjust the bridge tension to relax the paper web. | Used when warping worsens with increased speed. | Achieved at the cost of production efficiency. |

Tier 2: Process Control Solutions (“The Process Command Center”)

- Goal: Reduce problem frequency and stabilize quality through processes and standards.

- Applicable Scenario: Problems recur; you want to establish a long-term, stable quality control system.

| Solution | Concrete Actions & Standard Suggestions | Required Resources & Commitment | Solution Limitations |

| Liner Moisture Standard & Source Control | 1. Purchase a portable moisture meter. 2. Set a clear liner moisture standard: Incoming raw paper moisture deviation must not exceed ±2%. 3. Create records for different suppliers and batches. (This is a key part of a comprehensive Corrugated Board Grades and Paper Weight strategy). | Requires purchasing testing equipment and empowering QC to reject non-conforming materials. | Prevents problems but cannot solve moisture fluctuations created by the production line itself. |

| Speed-Steam Pressure Matching Chart | 1. Record the optimal steam pressure at different line speeds. 2. Create a simple reference chart posted at the control panel. | Requires technician time for data collection and summarization. | This relationship is not static; it becomes invalid with changes in paper, glue, or environment, requiring constant revision. |

| Single Facer & Double Backer Coordination | 1. Core Principle: Ensure the single-face web enters the double backer with its temperature and humidity within a controllable range to prevent cardboard strength loss. 2. Avoid the single-face being over-dried before entering the double backer. | Requires the production manager to coordinate the two sections. | Places higher demands on the inherent stability and control precision of the equipment. |

| Shop Floor Environment Stability | 1. Ensure a relatively stable temperature and humidity in the production area, especially near paper roll storage and the line. 2. Avoid drafts or steam leaks directly hitting the board. | Requires basic management of the workshop environment. | Addresses secondary moisture exchange post-production, not inherent defects from the production process. |

Tier 3: Systemic Root Cause Solutions (“The Deterministic Production System”)

- Goal: Permanently eliminate the physical root causes of moisture fluctuation at the equipment level.

- Applicable Scenario: When Tier 1 and Tier 2 solutions can no longer meet your demands for quality stability and cost control. This is the only fundamental path forward. This level delivers true, automated corrugated moisture control.

| Solution | What is it? (Core Capability & Principle) | Why use it? (Pain Point Solved) | How is it achieved? (Our Proven Technology) | What is the outcome? |

| Raw Paper Preheating & Humidification System | Rapid, uniform heating and precise humidification when needed of the paper web before it enters the corrugating rolls, ensuring the paper is in an optimal physical state when it reaches the core stages. | Solves insufficient preheating and subsequent gelatinization issues/warping caused by low initial paper temperature or cross-direction/local moisture variation. | Curved Preheating Plates + High-Pressure Spray System: • Curved Plates: Heat 70% faster than traditional cylinders, no water pooling, extremely fast thermal response for uniform preheating. • High-Pressure Spray: Mists overdry paper to directly adjust initial moisture content. | Ensures raw paper uniformity from the source, laying the foundation for stable production, Significantly reducing corrugated glue failure and warping from paper condition fluctuations, a major step in mastering corrugated moisture control. |

| Machine-Direction Pressure & Temperature Control | Segmented (along the machine direction) independent pressure and temperature control of the hot plates in the double backer section, ensuring uniform heating and stable pressure during bonding and setting. | Solves local glue failure and uneven bond strength from pressure variation, and warping from machine-direction temperature fluctuations causing uneven moisture evaporation rates. | Intelligent Pressure-Regulating Hot Plate System: • Independent Airbags/Cylinders: Deliver seamless, average, and stable pressure, preventing local corrugated glue failure. • Core Algorithm: Automatically adjusts pressure and hot plate temperature based on paper, flute type, and speed, dynamically adapting to different production conditions. | Achieves extremely flat board, eliminates local glue failure, ensures uniform bond strength, and enhances overall board rigidity, which is critical for maintaining the performance of your chosen flute profile (see our guide on How to Choose Your Corrugated Flute).Preventing cardboard strength loss. |

| Full-Line Thermal Stability System | Intelligent, centralized monitoring and control of the steam supply and temperature for the entire production line, ensuring a continuous, stable, and efficient heat supply for the gelatinization reaction. | Solves unstable gelatinization (over-gelatinization or false bonds) from steam pressure fluctuations and temperature失控, a root cause of glue failure and strength instability. | Full-Line Temperature Control & Steam System: • Three-Stage Hot Plate Control + Secondary Steam Utilization: Precise temperature control, energy-saving and efficient. • High-Precision Proportional Valves & Sensors: Ensure stable steam pressure and rapid response. • Siemens Control System: Acts as the reliable “brain” for unified coordination. | Achieves a “constant temperature and pressure” thermal environment for the line, providing deterministic conditions for high-quality bonding, virtually eliminating defects from thermal fluctuations, which is fundamental to preventing cardboard strength loss and ensuring successful corrugated moisture control. |

Chapter 4: The Jeytop Engineering Philosophy – Building “Determinism” into the Equipment’s Bloodline

Through the first three chapters, we have collectively completed a comprehensive analysis from diagnosis to solution. You may have noticed that each capability in the Tier 3 solutions is far from a simple upgrade of a single piece of equipment; it involves the deep synergy of mechanical design, control systems, and thermal engineering.

This is the crux of the matter. The fundamental reason you have been plagued by moisture issues is that your existing production line likely consists of components from different suppliers, following different standards, merely “mechanically spliced” together, unable to function and respond as a unified whole.

Jeytop’s “Integrated Manufacturing” model (as detailed in our article How to Choose a Corrugated Machinery Supplier) is designed to end this “patchwork” approach to production. Our philosophy is simple: What we deliver to you should not be a pile of parts that you need to debug and coordinate yourself, but a “production organism” that is deeply run-in ex-factory and possesses intrinsic determinism.

1. Core Component Self-Development: Mastering the “Determinism” of Performance

For the core links critical to moisture control, we insist on independent design and manufacturing, controlling quality from the source.

- For example, the Intelligent Pressure-Regulating Hot Plates: We understand that uniform pressure is the lifeline for ensuring gelatinization and flatness. Therefore, we self-develop the core seamless piston structure and control system to ensure average and stable pressure output, eliminating local defects caused by pressure variation. This cannot be guaranteed by purchasing off-the-shelf standard parts.

2. Systemic Integration: Achieving the “Determinism” of Collaboration

“A curved preheater that heats up quickly is futile if the steam pressure behind it is unstable.” — We eliminate this scenario of parts working in silos.

- Our approach is: Deeply integrate the Curved Preheating Plates, High-Pressure Spray System, Intelligent Pressure-Regulating Hot Plates, and the Full-Line Temperature Control System through our unified Siemens Control System (the brain). This system undergoes hundreds of linkage tests in our workshop before leaving the factory, with pre-set collaborative logic for different papers, flute types, and speeds.

- For you, this means: You receive a “ready-to-run” mature system. It can automatically and synchronously adjust preheating, spraying, pressure, and steam, like an experienced production team working in concert to deliver perfect corrugated moisture control, not a “parliament of parts” that you constantly need to mediate.

3. Standardization & Traceability: Guaranteeing the “Determinism” of Output

Our “Integrated Manufacturing” is also a rigorous standard system. All components, whether produced in our own factories or by coordinated manufacturing units, must pass the unified 《Jeytop Standard Quality Specification Book》 for acceptance.

- This translates in your plant to: Every piece of equipment you receive has predictable, reproducible core parameters (e.g., temperature control accuracy, pressure fluctuation range). The board quality produced today and tomorrow, by this machine and another of the same model, is highly consistent. This “determinism” is the ultimate guarantee for reducing your production management difficulty and quality risks.This applies to everything from mechanical tolerances to the **liner moisture standard** we expect from our raw material suppliers.

The Jeytop engineering philosophy is about transforming complex process issues like “corrugated moisture control” into a stable, predictable engineering outcome through precision design of underlying hardware, intelligent integration of top-level systems, and strict control of standards throughout the entire process.

We are not selling cold, hard steel. We are delivering a deterministic solution that consistently produces “flat, strong, and uniformly robust” quality board for you, directly addressing board warping causes and solutions, corrugated glue failure, and cardboard strength loss.

Conclusion & Call to Action

We have now provided you with the complete path for effective corrugated moisture control, from precise diagnosis and layered solutions to the fundamental way out.. You now possess all the knowledge to identify problems, handle emergencies, and even plan for the future. Mastering corrugated moisture control is within your reach.

Now, it’s time to translate this knowledge into tangible benefits for your workshop.

We offer you two clear paths to action:

- Download the “Corrugated Moisture Defect Quick Diagnostic & Emergency Handbook”

This carefully prepared PDF condenses the essence of Chapters 2 and 3 of this article, including the diagnostic flowchart and emergency solution list. You can print and post it in your workshop immediately, enabling your team to respond to sudden issues anytime. - Schedule a Free “In-Depth Production Line Moisture Stability Assessment”

If you are tired of recurring board warping causes and solutions and want to explore fundamental fixes,choose this option. To help us prepare efficiently, please provide:- Your main product types (e.g., e-commerce boxes, 5-ply heavy-duty cases).

- The defect type that troubles you most and its approximate occurrence rate (e.g., S-shape warping, ~5% rate).

- Your current production line’s average speed.

Based on this information, our engineers will prepare a targeted preliminary “System Upgrade Feasibility & ROI Analysis” brief for you.