You’ve picked the right flute profile for your box. Now it’s time to choose the “muscle” – the corrugated board grades and paper weight (grammage). This choice directly determines your box’s protective strength, printing quality, and overall cost-effectiveness. Getting the corrugated board grades right means your product arrives safely without paying for unnecessary material.

Understanding the Board’s Core Structure

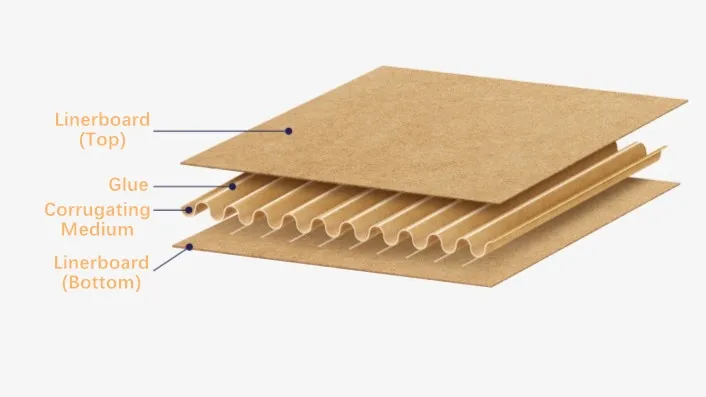

A corrugated board is a engineered composite material with two key components:

- Linerboard: This is the flat outer surface. Its quality dictates the box’s visual appeal and resistance to punctures. For high-quality printing, a smooth, consistent linerboard is non-negotiable.

- Corrugating Medium: This is the arched, fluted inner layer. It is the primary source of the box’s stacking strength (ability to withstand weight) and cushioning (protection against impacts).

Selecting the appropriate corrugated board grades is essentially about specifying the optimal paper weight for both the liner and the medium to meet your specific performance targets.

Paper Weight (Grammage) in Practical Terms

Paper weight, measured in grams per square meter (g/m²), is a direct indicator of material density and durability.

- A simple rule: Higher grammage yields a stiffer, stronger board but increases material cost. Lower grammage offers a lighter, more cost-conscious solution, suitable for less demanding applications.

To make an informed choice, focus on two key performance metrics derived from the paper’s properties:

- Ring Crush Test (RCT): This value predicts the box’s vertical stacking strength. A higher RCT rating means you can safely stack boxes higher in the warehouse or during shipping.

- Bursting Strength: This measures the board’s resistance to puncture and rupture. It’s a critical indicator of how well the box will handle rough handling.

Quick-Selection Reference Table

Use this table as a practical starting point to match your product needs with standard industry corrugated board grades and their typical paper weight configurations.

| Application | Linerboard (g/m²) | Medium (g/m²) | Key Focus & Rationale |

|---|---|---|---|

| Heavy-Duty Shipping | 200-300 | 150-180 | Maximize RCT. Heavy products and high pallet stacks demand superior compression strength from both liners and medium. |

| Retail Ready Boxes | 170-250 | 125-150 | Prioritize print surface. A smooth, mid-range liner ensures excellent graphics, while the medium provides sufficient structure for store shelves. |

| E-Commerce Boxes | 150-175 | 100-125 | Optimize the cost-protection balance. Lighter weights keep shipping costs down while providing adequate protection for most e-commerce goods. |

| Premium Packaging | 230-350 | 170-200 | Achieve premium stiffness and feel. Heavier, high-quality liners and medium create a rigid structure and a luxury in-hand experience for high-value products. |

Note: These are industry-standard ranges; actual selection should consider your specific supply chain and equipment capabilities.

Linking Your Choice to Production Reality

The perfect material specification on paper must be translated into consistent quality on your production floor. The choice of corrugated board grades directly impacts machine performance.

- On the Folder Gluer, switching between different paper weights often requires recalibrating compression and glue application settings. Incorrect settings for a heavier board can lead to poor crease quality or inadequate bonding.

- On the Printing Press, the surface consistency and absorbency of the linerboard are critical. Variations can lead to mottled print, poor ink adhesion, or excessive waste.

Therefore, achieving a seamless production run relies not only on selecting the right corrugated board grades but also on having equipment capable of maintaining precision and handling material variations effectively. Proper material selection combined with well-maintained equipment significantly reduces production waste and improves overall efficiency.

Need Help Applying This?

If you find yourself facing:

- Inconsistent box quality even when you’ve followed standard specifications.

- High waste rates and costly downtime during changeovers between different paper grades.

Let’s schedule a quick, focused call. We can help you diagnose the root cause, whether it’s in material selection, equipment configuration, or your operational workflow, and find a practical solution.