Pick Your Corrugated Flute:

Ever had that sinking feeling?

- Your shipped boxes arrive crushed, with damaged goods inside.

- Your premium product’s packaging looks cheap with a blurry, misprinted logo.

Often, the root cause is a fundamental choice: selecting the wrong corrugated flute profile.

Think of the flute as the skeleton of your box. Get it right, and your products are protected, your costs are optimized, and your brand looks professional.

This guide cuts the jargon and gives you the plain facts on how to choose.

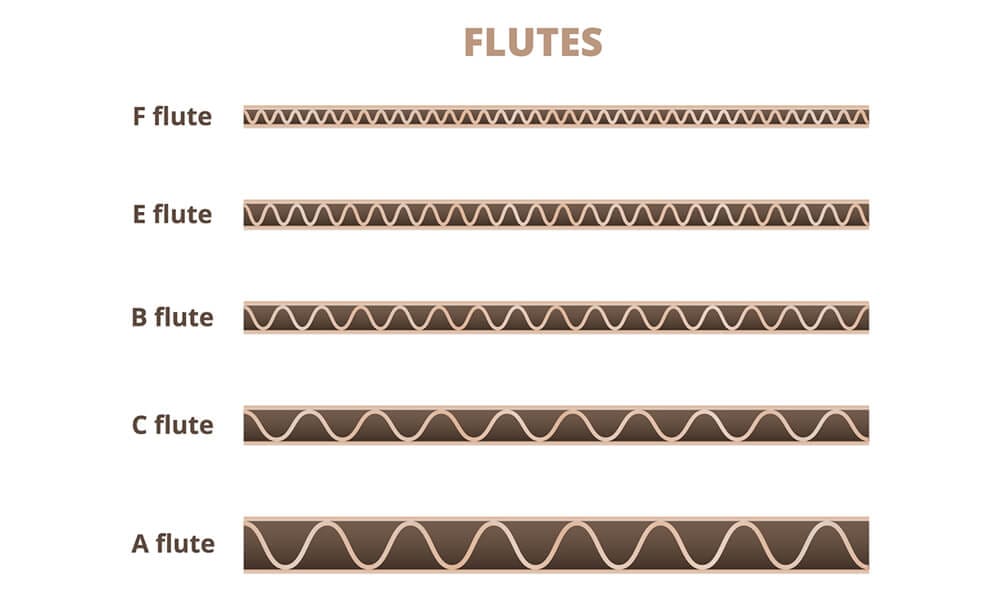

The Flutes, Decoded

| Flute Profile | The Simple Lowdown | Best For (Real-World Use) |

|---|---|---|

| A-Flute | The Cushion Master: Thick, springy, superior shock absorption. | Heavy items, fragile products (e.g., ceramics, glass, machinery parts). |

| B-Flute | The Tough Guy: Dense, flat, great puncture resistance. | Retail-ready boxes, canned goods, inner partitions. |

| C-Flute | The All-Rounder: A balanced mix of stacking strength and crush resistance. | Your go-to for general shipping cases. |

| E-Flute | The Looker: Thin, rigid, offers an excellent printing surface. | Consumer electronics, cosmetics, high-end food packaging. |

| F-Flute | The Refined One: Ultra-thin for a sleek, premium feel. | Luxury goods, branded apparel, premium gift boxes. |

Quick Questions Answered

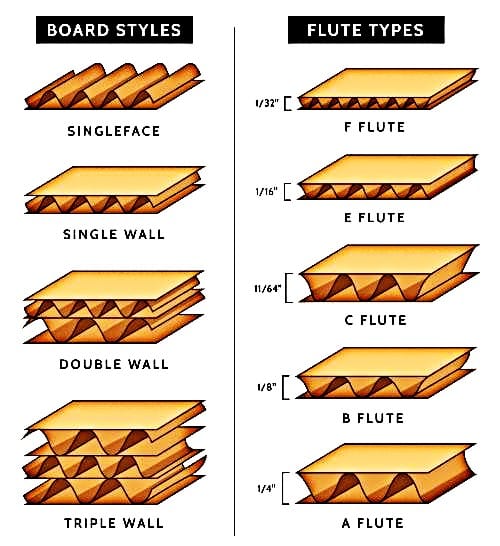

➤ What about combo flutes like BC?

Answer: That’s using a “dream team.” BC flute, for instance, combines the strength of C-flute with the flat surface of B-flute, ideal for boxes that need to be both durable and look great.

➤ Myth: More flutes always = stronger?

Answer: Not exactly. An A-flute box with weak paper will still fail. The right flute + the right paper grade is the secret to cost-effective strength.

Knowing the theory is one thing. But producing perfect boxes consistently on your production line is another. Issues like cracked scores on delicate E-flute or high waste when switching from C to F flute often point back to one thing: the precision and stability of your folder gluer.

A machine that holds its settings and adjusts accurately is key to turning good board into great boxes—with less waste and downtime.

The table is yours to use. We hope it helps you make smarter, more confident decisions.

Want to take the next step?

If you’re also facing:

- Frequent machine adjustments eating into production time?

- Unexplained high waste rates, especially with thinner boards?

Let’s schedule a quick chat. We can usually spot the main issue in about 15 minutes and see if there’s a smarter way forward.