Solve the Classic Dilemma in Corrugated Box Making with Jeytop’s Integrated Manufacturing Model

The Corrugated Machinery Procurement Dilemma

Choosing the right corrugated machinery supplier is one of the most critical decisions a box plant manager or owner will make. Imagine this: You’re tasked with upgrading your corrugated box production line. The market demands higher quality, more complex packaging, and your board of directors is demanding a clear return on investment. You start researching corrugated machinery suppliers, and quickly, you’re faced with a critical—and seemingly impossible—choice.

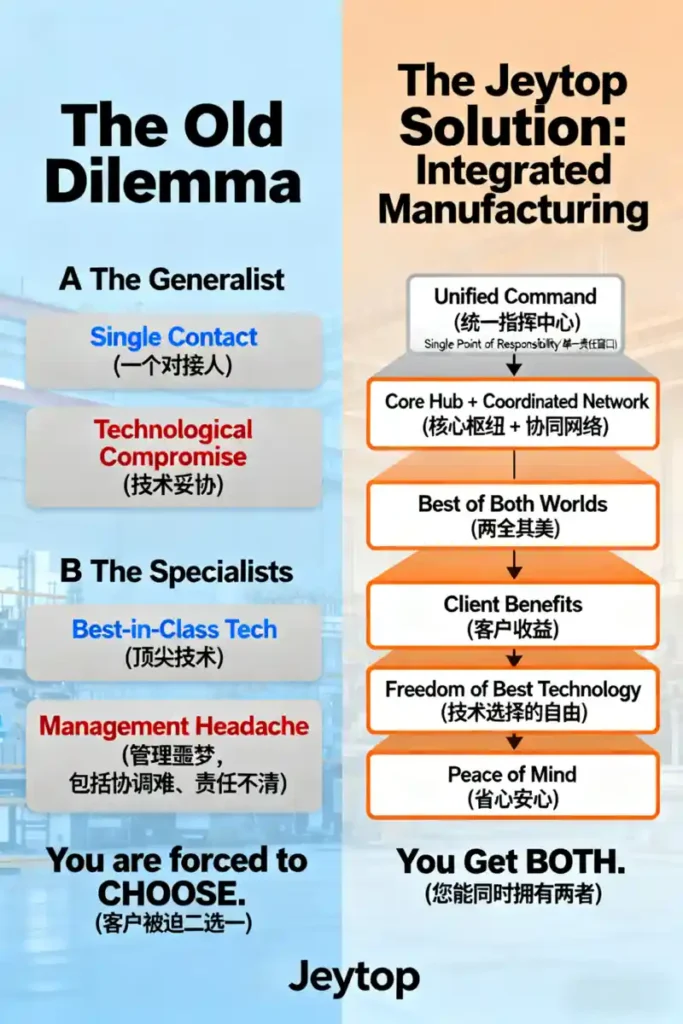

On one hand, you have the large, single-supplier. They promise a one-stop-shop solution. The sales pitch is compelling: “We handle everything. One contract, one point of contact.” It sounds efficient. But a nagging doubt remains. Can one manufacturer truly be the world’s best at every single component? From the corrugating roll and the hotplate section to the precision of a high-speed folder gluer line and the intricacies of a rotary die-cutter? History and common sense suggest they cannot. You risk investing in a line where some parts are exceptional, but others are merely adequate, creating a chain that’s only as strong as its weakest link.

On the other hand, you have the option to hand-pick a “dream team” of specialized corrugated machinery. You source the finest corrugator from one expert, the best printer-slotter from another, and the most reliable folder-gluer from a third. You’re guaranteed best-in-class technology for each stage. However, this path introduces a different kind of monster: managerial chaos. You now have three different contracts, three project timelines to synchronize, three sets of engineers who don’t communicate, and a terrifyingly clear picture of who will be blamed when the lines between their machines become a no-man’s-land of technical glitches and finger-pointing. This is the core challenge that a reliable corrugated machinery supplier must solve for its clients.

This is the “Specialized Tech vs. Single Source” dilemma, a false choice that has plagued buyers of corrugated box making equipment for decades. It forces you to trade technological excellence for managerial simplicity, or vice-versa. But what if this compromise was no longer necessary?

The Flawed Foundation of the Traditional Corrugated Equipment Supply Chain

To understand the solution, we must first diagnose the problem’s root cause. The traditional corrugated machinery supply chain is structurally binary, built on an “either-or” premise.

The “Jack-of-All-Trades, Master of None” Supplier:

The fundamental limitation of a single, generalist supplier is the dilution of expertise. No single R&D department has infinite resources. Focusing on excellence across a dozen different corrugated machine categories is a monumental task. Often, this means their core product might be excellent, but the ancillary equipment is sourced from sub-contractors and rebranded, or developed with less focus. You, the customer, may not be getting a uniformly “best-in-class” line, but rather a line built around one or two core competencies, with the rest being filler. The promise of simplicity comes at the hidden cost of technological compromise.

The “Managerial Nightmare” of a Multi-Supplier Project:

Choosing multiple specialists seems like the answer to the technological compromise, but it unveils a Pandora’s Box of hidden costs that far exceed the initial purchase price:

- Technical Interface Risks: Machines from different manufacturers are not designed to “speak” to each other. You face challenges in mechanical interfacing (line speed synchronization), electrical integration (different PLC systems), and data communication. Making Line A from Germany talk to Line B from Italy can become an engineering project in itself.

- Project Management Overhead: You become the de facto general contractor. Your team will spend countless hours in meetings, on calls, and writing emails just to coordinate delivery schedules, installation sequences, and interface specifications. This immense project management overhead is a hidden tax on your productivity.

- The Accountability Black Hole: When a production issue arises—for instance, a board jam that occurs between the printer and the folder-gluer—the “specialists” will almost inevitably point fingers at each other. You are left in the middle, holding the bag of lost production and revenue, with no single party taking ultimate responsibility.

This is the broken paradigm. You are forced to choose between suboptimal technology and an unmanageable project. But a new model has emerged that shatters this outdated compromise.

Deconstructing the Jeytop Integrated Manufacturing Model

We founded Jeytop Industrial Group on a simple, radical idea: our clients should not have to choose. They deserve both technological freedom and managerial simplicity. This conviction led to the creation of our Integrated Manufacturing Model, a three-layered structure designed to function as a single, cohesive “Super-Factory” for the corrugated packaging industry.

Layer 1: The Core Hub – Our Brain, Heart, and Final Assembly Center

At the center of our ecosystem is our own core manufacturing facility. This is not just a production plant; it is our Center of Excellence for R&D, Quality Doctrine, and Final Integration. Here is where we prove our deep dedication to the manufacturing craft, maintaining fundamental control over quality, cost, and delivery for all our corrugated machinery solutions.

- Technical Leadership & Standards: Here, our engineers develop proprietary technologies, design the final equipment blueprints, and author the uncompromising Jeytop Standard Quality Specification Book. We don’t just set the standard; we are its ultimate enforcer.

- Depth in Manufacturing: We possess deep manufacturing capabilities for critical structural components, base frames, and the overarching electrical control systems—the brain that synchronizes the entire production line. This ensures the fundamental integrity and performance of every solution we deliver.

- The Final Integration Point: This is a critical differentiator. All modules and components, regardless of their origin within our group, converge here for final assembly, comprehensive line synchronization, and pre-shipment testing. Every machine we deliver is fully assembled and test-run as a complete unit in our workshop, guaranteeing deterministic performance before it ever reaches your floor.

Layer 2: The Coordinated Manufacturing Network – Our Specialized Limbs and Extensions

This is how we achieve unparalleled technological breadth in corrugated box making equipment. Our network consists of manufacturing units that have been rigorously certified by us as top-tier experts in their specific domains (such as high-end sheet metal fabrication, precision welding, or specialized functional modules).

- An Arm of the Group: These are not distant, anonymous subcontractors. They function as integrated, specialized extensions of the Jeytop group, operating under our direct management and quality oversight.

- The “Super-Factory” Advantage: This structure allows us to operate like a “Super-Factory,” offering clients a range of specialized technology that would be impossible for any single plant to house under one roof. You get access to the best-specific expertise, curated and managed by us. This integration can yield concrete efficiencies, such as reducing changeover times on a folder gluer line from 30 minutes to under 10 minutes, directly boosting your flexibility and output.

Layer 3: The Unified Command – Our Central Nervous System

This is the magic that binds it all together. Jeytop acts as the single, unified command center for every project. From the moment you engage with us, you have one dedicated Jeytop Project Manager who serves as your sole point of contact and accountability.

Our command system ensures:

- A Single Contract and Single Point of Responsibility: You sign one contract with Cangzhou Jeytop Industrial Group Co., Ltd. We assume full legal and financial responsibility for the entire line.

- Seamless Integration by Design: Our core factory engineers design the key interfaces and the control system from the outset, ensuring mechanical, electrical, and software harmony from the ground up.

- End-to-End Project Management & Final Assembly: We manage all internal and coordinated manufacturing units. Crucially, the final assembly, system integration, and testing always take place at our core facility.

- Uncompromising Quality Control: Every component must pass the same rigorous checks against the Jeytop Standard. The final Factory Acceptance Test is conducted by us, under one roof, and we issue the final certificate of conformity.

Why the Integrated Model Matters Now: Addressing Modern Supply Chain Challenges

In today’s global manufacturing landscape, marked by volatility and a pressing need for resilience, the old ways of sourcing equipment expose you to significant risk. A corrugated machinery supplier must be a partner in stability. Our Integrated Manufacturing Model is engineered to provide a bulwark against these modern challenges.

Consider the fragility of extended, global supply chains. A disruption thousands of miles away can halt your production expansion for months. Our model, with its roots in the robust manufacturing clusters of Dongguang and its coordinated local network, drastically shortens and secures the supply chain for key packaging materials like corrugated fiberboard.This translates to greater predictability in your project timeline and insulation from global shocks.

Furthermore, in an era of tight margins, controlling the total cost of ownership is paramount. By maintaining deep manufacturing capabilities at our Core Hub, we exert fundamental control over the cost and quality of the most critical components. This allows us to deliver superior value and protect your investment from the price volatility that often comes with fully outsourced production.

We build certainty into the very fabric of your production line.

What to Look For in a Modern Corrugated Machinery Supplier

When evaluating your next corrugated machinery supplier, look beyond the brochure and the standard specifications. The key is to identify a partner who provides a holistic solution to the specialist-vs-generalist dilemma, not just a collection of machines. This is the new benchmark for a leading packaging machinery supplier. You need a partner with a proven model that guarantees both technological excellence and project simplicity. This is exactly the gap that Jeytop’s Integrated Manufacturing Model is designed to fill. It is the definitive answer for those seeking a corrugated machinery supplier that has consciously moved beyond the outdated trade-offs of the past.

The Tangible Benefits of an Integrated Corrugated Machinery Supplier

So, what does this model actually feel like for you, the customer? It translates into two powerful, tangible benefits.

Benefit 1: The Freedom to Configure Your “All-Star” Line with Precision.

With Jeytop, you are no longer limited by the catalog of a single factory. You are consulting with the management of a “Super-Factory.” We analyze your specific needs—your products, your raw materials, your output goals—and then we configure the optimal solution. For instance, if you need to run ultra-lightweight, micro-flute boards, a generalist might force a compromise. We, however, can deploy the specific folder-gluer unit renowned for its gentle handling of delicate board, ensuring you don’t sacrifice quality for speed. This process ensures you get a high-performance corrugated line tailored for your unique needs. Explore our range of corrugated machinery solutions to see the possibilities.

Benefit 2: The Peace of Mind of a Single-Throat-to-Choke.

This is the ultimate liberation from managerial burden. Imagine a complex issue arises that seems to span the interface between the printer and the die-cutter. In a multi-supplier setup, you are now a project manager, a technical arbiter, and a referee. With Jeytop, you are none of those. You make one call to your Jeytop Project Manager. We dispatch our engineers, who diagnose the root cause—whether it originated in a component we made or one a coordinated unit made—and we own the solution. You are free to focus on running your business, not managing your suppliers. This is the core of our promise: deterministic delivery and hassle-free procurement. For a deeper dive into how we manage projects, you can review some of our successful case studies.

A Southeast Asian Success Story

A prominent packaging manufacturer in Vietnam needed to expand its capability to produce high-value, complex-condition boxes for the electronics industry. They needed a new 5-ply corrugating line and a high-precision finishing line.

Their dilemma was classic when evaluating corrugated machinery suppliers: a single supplier could offer a full line but lacked the cutting-edge expertise in precision finishing. Approaching two separate specialists for the corrugator and the finisher seemed technologically ideal but was deemed too risky from a corrugated line project management standpoint.

The Jeytop Solution:

We conducted a deep-dive analysis and proposed an integrated solution:

- Line Design & Core Control: The overall line layout, critical structural frameworks, and the unified electrical control system (the line’s brain) were entirely designed and manufactured by our Core Hub, ensuring we maintained fundamental control over the line’s performance and integrity.

- Specialized Module Deployment: We deployed our specialized manufacturing units focused on folder-gluer technology and die-cutter technology to incorporate their peak expertise into the project.

- Final Integration & Delivery: All modules were delivered to our core facility for final assembly, complete line synchronization, and pre-shipment testing, ensuring it was delivered as one harmonious, fully-vetted production line.

The Result:

The project was completed ahead of schedule, benefiting from our localized and closely-managed supply network. More importantly, the integrated line achieved an OEE increase from an industry average of 85% to 92%, enabling the production of an additional 12,000 boxes per month, thanks to perfect synchronization and the superior performance of each specialized module. The result demonstrated the value of choosing an integrated corrugated machinery supplier. The client’s project director summarized it perfectly: “We got the specialized technology we were desperate for, but the experience was as simple and secure as dealing with one primary manufacturer. Jeytop’s command of the entire process was clear.”

Answers to Common Questions from Box Plant Managers

We understand that a new model brings thoughtful questions. Here are answers to the ones we hear most often from leaders like you.

Question: “How do you ensure consistent quality across different manufacturing units?”

Answer: This is the core of our value proposition. Beyond final inspection, it’s about proactive process control. Our full-time Jeytop Quality Engineers are stationed at partner facilities during key production stages. They don’t just inspect the final product; they audit the manufacturing process itself against the rigid Jeytop Standard Quality Specification Book. No unit can proceed to the next stage without their explicit sign-off. This is a system of embedded governance, not a hopeful spot-check, ensuring every component bears the same mark of quality.

Question: “What happens if a specialized unit faces a delay? How does that impact my overall project timeline?”

Answer: Our model is designed with built-in risk mitigation. Because we are the central command, we have complete visibility into each unit’s progress and capacity. This allows us to foresee potential delays and proactively re-sequence tasks to absorb them. In the event of a significant, unforeseen delay, as your single point of responsibility, we leverage our network to find an alternative solution or re-allocate resources—all while managing the communication and accountability on our side. Your project timeline remains our immutable commitment, and we have the tools and authority to defend it.

Making the Informed Choice for Your Corrugated Box Production

The “Specialized Tech vs. Single Source” dilemma is a relic of an outdated supply chain. You no longer need to force your business into this false choice. The Jeytop Integrated Manufacturing Model exists to deliver both: the technological freedom of hand-picked specialists and the managerial simplicity of a single, accountable partner.

This is the new standard you should demand from any corrugated machinery supplier. It is the difference between buying a collection of machines and investing in a deterministic production outcome.

We have built our entire operation around this model to give you, the box plant owner or manager, something more valuable than just equipment: clarity and confidence in your investment.

Want to learn more first? Download our free guide: “3 Key Metrics for Choosing a Corrugated Line with Integrated Manufacturing.”

Ready to solve the classic supplier dilemma? Contact Jeytop today for a complimentary, in-depth consultation. We will map your production goals against our ecosystem of specialists and provide you with a preliminary integration concept for your next project.