For corrugated box plant managers in emerging markets, today’s environment is both challenging and full of opportunity. The e-commerce boom has brought an endless stream of orders, but it also demands faster delivery, higher flexibility, and tighter cost control. Many factory owners face the “growth paradox”: sales are rising, but profits are eroded by soaring labor costs, inefficient processes, and increasingly demanding customers.

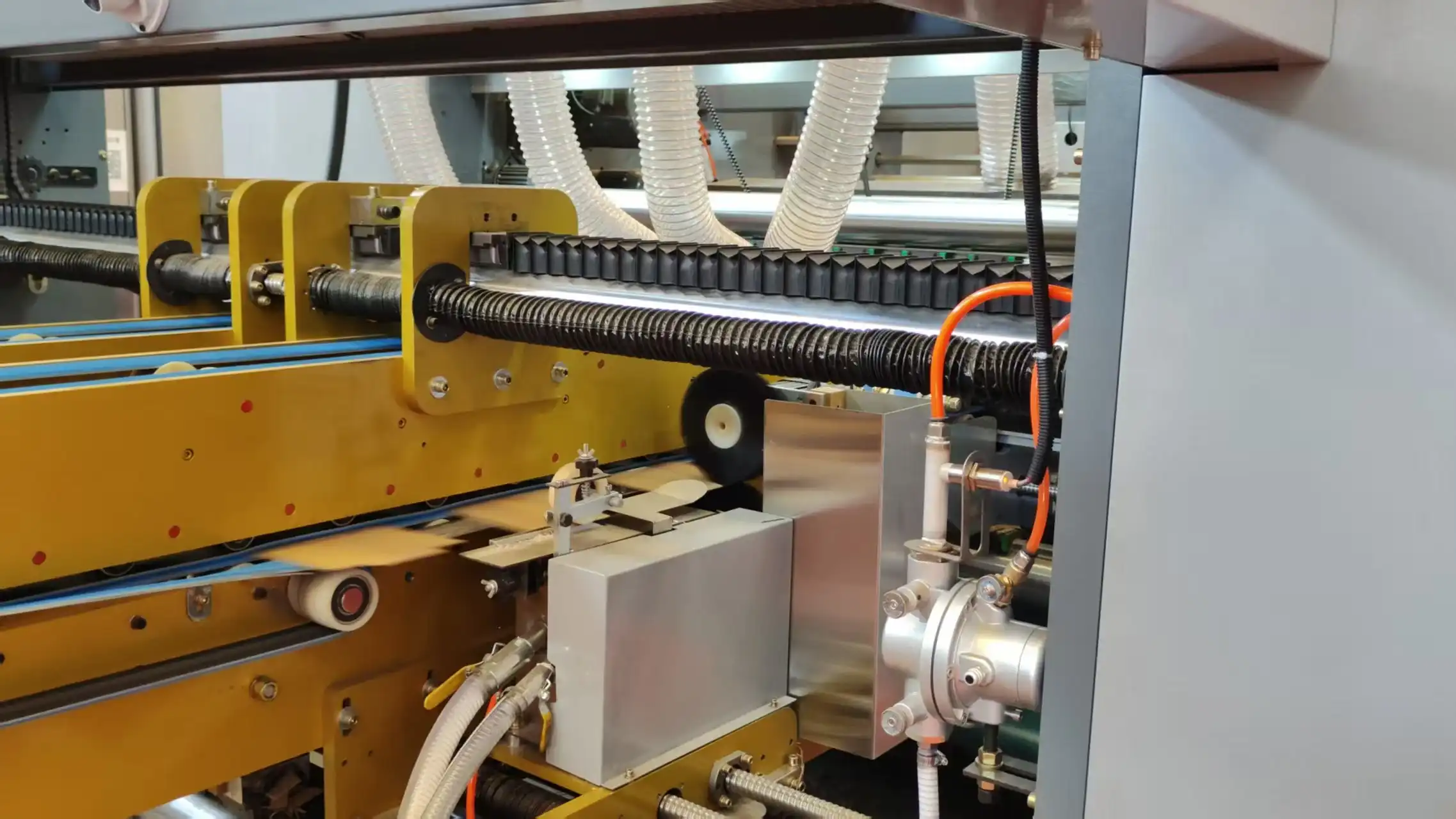

This guide provides a practical framework for evaluating automation investments, helping you make the smartest, lowest-risk decisions in upgrading your corrugated box production line with a modern Flexo Folder Gluer Line.

The “New Normal”—Profit Challenges Behind Growth

Global e-commerce parcel volume has grown by more than 50% in the past three years, including markets in Southeast Asia, the Middle East, Latin America, and Africa. Yet this growth has not translated into equal profit increases for corrugated box plants. Instead, most plants face core challenges such as:

- Soaring Labor Costs: Skilled operators demand higher wages and are harder to recruit. Managing large teams is costly and time-consuming.

- Efficiency Bottlenecks: Traditional standalone machines (printer, die-cutter, folder-gluer) require excessive handling and waiting time, limiting efficiency and making it difficult to meet “small batch, multiple order” demands.

- ROI Concerns: European premium equipment performs well but requires high investment and long payback periods (often 3–5 years), discouraging cautious investors.

- Quality Instability: More production stages increase the risk of issues like misregistration or weak bonding, which directly impact brand reputation.

These are symptoms of an outdated production model. Sticking to old equipment means paying ongoing “hidden costs.” A modern Flexo Folder Gluer Automation Line offers a proven path forward.

A Framework for Evaluating Flexo Folder Gluer Lines

The right Flexo Folder Gluer Line can transform your corrugated box plant. To cut through marketing claims, use a structured evaluation model based on five key dimensions:

1. Overall Equipment Effectiveness (OEE) – Solving Efficiency Bottlenecks

- Key Issue: Standalone machines lose production time with repeated loading, setup, and adjustments.

- Evaluation Point: Look at average hourly output of the integrated line, not just peak machine speeds.

- Professional Tip: Ask suppliers for OEE data under real conditions (e.g., 8-hour run with 2–3 changeovers). A reliable Flexo Folder Gluer Line should achieve OEE above 85%.

2. Return on Investment (ROI) – Addressing Cost Pressures

- Key Issue: Can the investment pay back quickly and generate sustainable benefits?

- ROI Framework:

- Hard Savings:

- Labor reduction: (Current operators – operators with new line) × annual salary × 1.3.

- Waste reduction: (Current waste – new waste) × daily output × cost × working days.

- Soft Benefits:

- Extra profit from increased capacity.

- Space savings from compact layout.

- Reduced management overhead.

- Hard Savings:

- Action Tip: Use Jeytop’s ROI Calculator to generate an accurate payback analysis tailored to your plant.

3. Operational Costs & Stability – Ensuring Long-Term Reliability

- Key Issue: Is the Flexo Folder Gluer Line energy-efficient, durable, and stable?

- Checkpoints:

- Servo-driven systems for lower energy use.

- Strong cast iron frames and precision gear grinding for long service life.

- Features like automatic registration and glue monitoring to guarantee consistent quality.

4. Flexibility – Handling Diverse Orders Efficiently

- Key Issue: Can the line manage quick changeovers and complex box styles?

- Evaluation Points:

- Job parameter memory for one-click setup.

- Quick-lock systems for die and anilox roll changes.

- High-precision die-cutting units for specialty boxes.

5. Technical Support Ecosystem – Eliminating Overseas Procurement Risks

- Key Issue: How fast can you get support when needed?

- Checklist:

- Professional installation and operator training.

- Multi-channel support (phone, email, WhatsApp/WeChat) with guaranteed response times.

- Clear spare parts strategy and logistics lead times.

By evaluating a Flexo Folder Gluer Production Line across these five dimensions, you shift from passive buyer to proactive decision-maker.

Market Insight—Jeytop’s Value Innovation

The perception of “Made in China” has shifted. Today, packaging machinery from industrial hubs like Dongguang, Hebei, delivers both scale and quality. Jeytop is a key driver in this transformation, offering:

- Value-Engineered Design: Modular, standardized design with international-grade components (Japanese servo motors, German pneumatics) for reliability, combined with cost-optimized non-core structures.

- Adaptation for Emerging Markets: Equipment is engineered for local conditions such as humidity, recycled paper usage, and unstable power grids. Example: Jeytop’s intelligent glue system prevents premature curing in hot climates.

- Lifetime Service Ecosystem: Beyond machinery, Jeytop provides long-term security with on-site commissioning plus lifetime online support through WhatsApp video calls, resolving most issues within hours.

Case Study—Why a Vietnam Plant Chose Jeytop

In 2023, a corrugated box factory in Hanoi sought a Flexo Folder Gluer Line with ROI under two years to meet e-commerce growth. After evaluating global brands, they chose Jeytop.

Reasons for the Decision:

- Proactive Support: Jeytop tested AA-flute board compatibility in advance to ensure performance.

- Transparent ROI Modeling: Jointly built an ROI model showing payback through labor savings, higher output, and reduced waste.

- Fast Response Commitment: Confidence in Jeytop’s online technical support and response times.

Customer Testimonial:

“Choosing Jeytop was a very successful cooperation. The equipment runs stably and meets our expectations. Their service team is particularly praiseworthy for quick responses. Even on weekends, remote support solved issues quickly, ensuring smooth production.”

Risk Mitigation—5 Questions to Ask Before Buying

Before signing a contract for a Flexo Folder Gluer Line, protect your investment by asking:

- What are your exact commitments for technical support response time?

- How is your equipment adapted for my factory’s environment (voltage, humidity, dust)?

- Can you provide a recommended spare parts list and service partner contacts?

- Can we include performance-based acceptance terms (speed, accuracy, waste rate) in the contract?

- What are all additional costs for installation, commissioning, and training?

Your Next Steps—Exclusive Resources for Box Plants

Jeytop helps you make confident decisions in upgrading your Corrugated Box Production Line with a Flexo Folder Gluer Automation Line. Access these free resources:

- Download the Corrugated Plant ROI Calculator (Excel tool for payback analysis).

- Get the 2024 Corrugated Packaging Automation Whitepaper.

- Book a Free 30-Minute Technical Consultation with Jeytop experts.

Jeytop Machinery – Your Trusted Intelligent Packaging Solutions Partner

🌐 Website: www.jeytop.com

📂 Resource Center: Gallery – Jeytop Carton Machinery

📧 Email: jeytopmachinery@163.com

📱 WhatsApp: 86 15230792110