With the continuous advancement of technology in the corrugated packaging industry, more and more customers are demanding higher printing quality for corrugated boxes. From the beginning of simple one-color, two-color, and three-color printing, the industry has developed into widely applied four-color and five-color overprinting, and now into six-color, seven-color, and even eight-color high-definition flexo printing technology. With the increase of printing units, packaging not only looks more vivid, but it also pushes the development of flexo printing technology further.

Although multi-color flexo printing is an environmentally friendly printing method that has replaced many offset products and has broad prospects, according to my understanding of the industry, there are still relatively few enterprises that can fully apply this technology well. Many business owners purchase multi-color high-definition flexo printing machines, but most fail to utilize the real capabilities of the equipment. Some even use them only for ordinary printing jobs, which undoubtedly discounts the machine’s performance and causes asset waste.

This article shares several techniques from years of management experience in multi-color high-definition flexo printing as a reference for industry colleagues.

1. Understand Equipment Configuration Parameters

When purchasing high-definition flexo printing equipment, enterprise leaders must understand the positioning of their own product packaging printing. It is necessary to configure the equipment according to the characteristics of the enterprise’s packaging and printing needs.

Key configuration elements include:

- The line count of the anilox roller

- The number of units for doctor blade and rubber roller inking systems

- Top printing or bottom printing

- Whether to configure slotting or die cutting units

Importance of Anilox Roller Line Count

The line count configuration must consider solid areas, fine text and lines, spot colors, and CMYK four-color images.

| Line count (L/in) | Applicable products | Remarks |

|---|---|---|

| 550—700 | Very fine tonal work | CMYK, steel chamber doctor blade inking |

| 440—550 | High-quality tone and gradient | CMYK, fine text, lines, plastic chamber doctor blade inking |

| 300—400 | General tone and gradient | Plastic chamber doctor blade inking, rubber roller inking |

| 180—280 | Ordinary solid areas or varnish | Rubber roller inking |

Top printing vs. Bottom printing

- Top printing: printed side faces up → avoids smudging (recommended).

- Bottom printing: printed side faces down → more smudging, especially in winter.

Recommendation: choose top printing, and if machines include slotting or die cutting units, always add a drying unit to reduce smudging and print waste.

2. Maintain the Anilox Roller

The anilox roller is the core component of a flexographic printing machine. Print quality is directly tied to it. Maintenance is crucial.

Key practices:

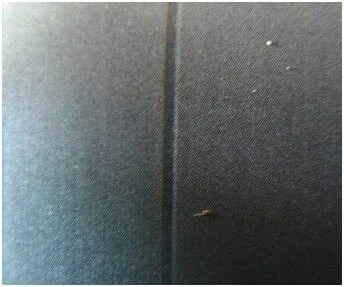

- Clean with clean water after printing → avoid impurities that cause scratches(as shown above) and print defects.

- Use clean ink → always filter ink before use to prevent roller damage.

- Use clean wiping cloths → dirty cloths with sand or debris will scratch rollers and plates.

- Clean the anilox roller regularly → dried ink in hexagonal cells reduces ink transfer, causing uneven color. Weekly deep cleaning is necessary.

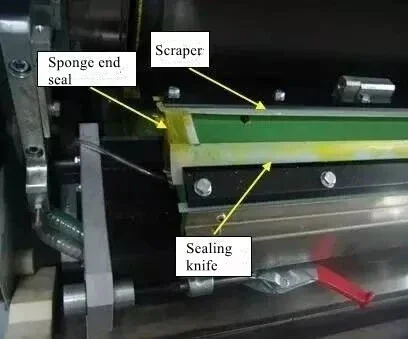

- Do not ignore the chamber doctor blade → clean it at the end of every shift; check sponge seals to prevent leakage.

Neglecting anilox roller care not only shortens machine life but also leads to inconsistent print quality.

3. Importance of Prepress Proofing

High-definition flexo printing cannot directly copy offset prepress methods. Prepress proofing and design adjustments are essential.

- Registration accuracy: offset is extremely precise, while flexo presses may have ~0.2 mm error, combined with corrugated board flatness → leads to misregistration in fine details.

- Dot density: since flexo is a wet-on-wet process, dot density >75% causes drying issues and ghosting. Designers must control density.

- Digital artwork only: using hard copies often causes color deviation, since flexo dots expand during printing. Always use digital originals.

Without prepress adjustments, even the best flexo equipment cannot deliver the intended results.

4. Control Printing Pressure

In high-definition flexo printing, pressure must be precisely controlled:

- Too much inking pressure → ink squeezes to edges, causing doubling.

- Too little pressure → incomplete ink transfer.

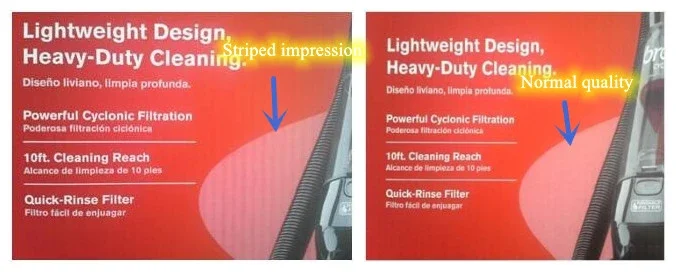

- Too much printing pressure → rib marks on corrugated board.

Proper adjustment depends on board thickness, plate thickness, and printing speed. Careful control ensures stable quality.

5. Do Not Ignore Ink Viscosity and pH

Ink behavior changes during printing. Controlling viscosity and pH is essential.

- Viscosity naturally increases as solvent evaporates → unchecked, it causes blocking, dot filling, and color variation. Ink must be checked every 30 minutes.

- The pH of water-based ink should remain 8.2–9.5:

- Above 9 → viscosity too low, drying slows, water resistance weakens.

- Below 8.2 → viscosity too high, dries too fast, clogs anilox cells.

Always keep pH stabilizers from ink suppliers on hand to make timely adjustments.

Conclusion

Of course, besides the five techniques above, there are many other factors affecting high-definition flexo printing, such as plate making, board quality, ink formulation, press operation, and process management. All these require practitioners and technical managers to study carefully and accumulate experience.

At Jeytop, we are dedicated to helping corrugated packaging manufacturers improve efficiency, reduce costs, and achieve sustainable growth. Whether you are planning to upgrade your production line or looking for a reliable partner in corrugated box machinery, we provide tailored solutions to meet your specific needs.

Our promise: Quality, Trust & Value.

📞 Contact us today to discuss your project or request a customized solution:

- Email: jeytopmachine@163.com

- Whatsapp: https://wa.me/8618833771152/

- Website: www.jeytop.com

Let’s work together to build a stronger future for your packaging business.