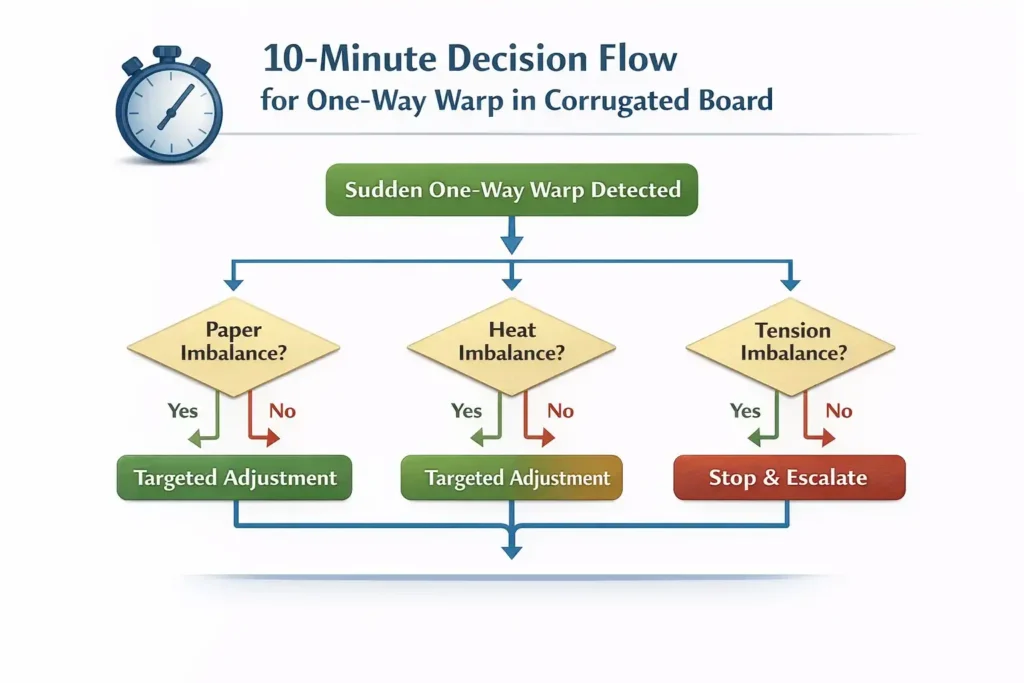

Sudden One-Way Warp in Corrugated Board? Don’t Touch the Speed—Check These Three Things First

Sudden one-way warp on a corrugator line is rarely a speed problem.When warp suddenly worsens in one direction, adjusting speed only masks the real issue. This 10-minute checklist helps operators quickly identify whether the root cause lies in paper condition, heat imbalance, or mechanical tension—before ineffective adjustments turn a minor imbalance into scrap or downtime.