Key Features

- Precision Heating System:

- Equipped with grinding-treated heating plates, made from certified pressure vessel plates compliant with national standards.

- Heating plates are constructed with internal partition structures for efficient steam circulation, enabling effective steam-water separation and enhanced heat utilization.

- Multi-section temperature control with temperature display ensures precise adhesive curing.

- High-Performance Cooling Section:

- Includes a cooling section for stable board shaping and improved quality.

- Advanced Conveyor Systems:

- Upper conveyor features automatic lateral alignment and pneumatic tensioning with dual S-cylinder tensioning devices for stable operation.

- Lower conveyor includes a manual S-shaped correction and tensioning system, offering simple yet practical operation.

- Reliable Drive System:

- Main drive motor is a variable-frequency motor, delivering high torque at low speeds and a wide speed adjustment range for stable and reliable operation.

- Drive rollers are coated with wear-resistant rubber and feature a crown profile to ensure smooth and flat board output.

- Enhanced Durability and Safety:

- Main frame built from high-strength national standard materials for robustness and aesthetic appeal.

- Pneumatic spring press plate system ensures reliable performance under high-speed conditions.

- Energy Efficiency:

- Steam circulation designed in an S-shaped flow enhances heating efficiency, reducing energy consumption.

- Premium Electrical Components:

- Internationally renowned brands for electrical components ensure operational stability and reliability.

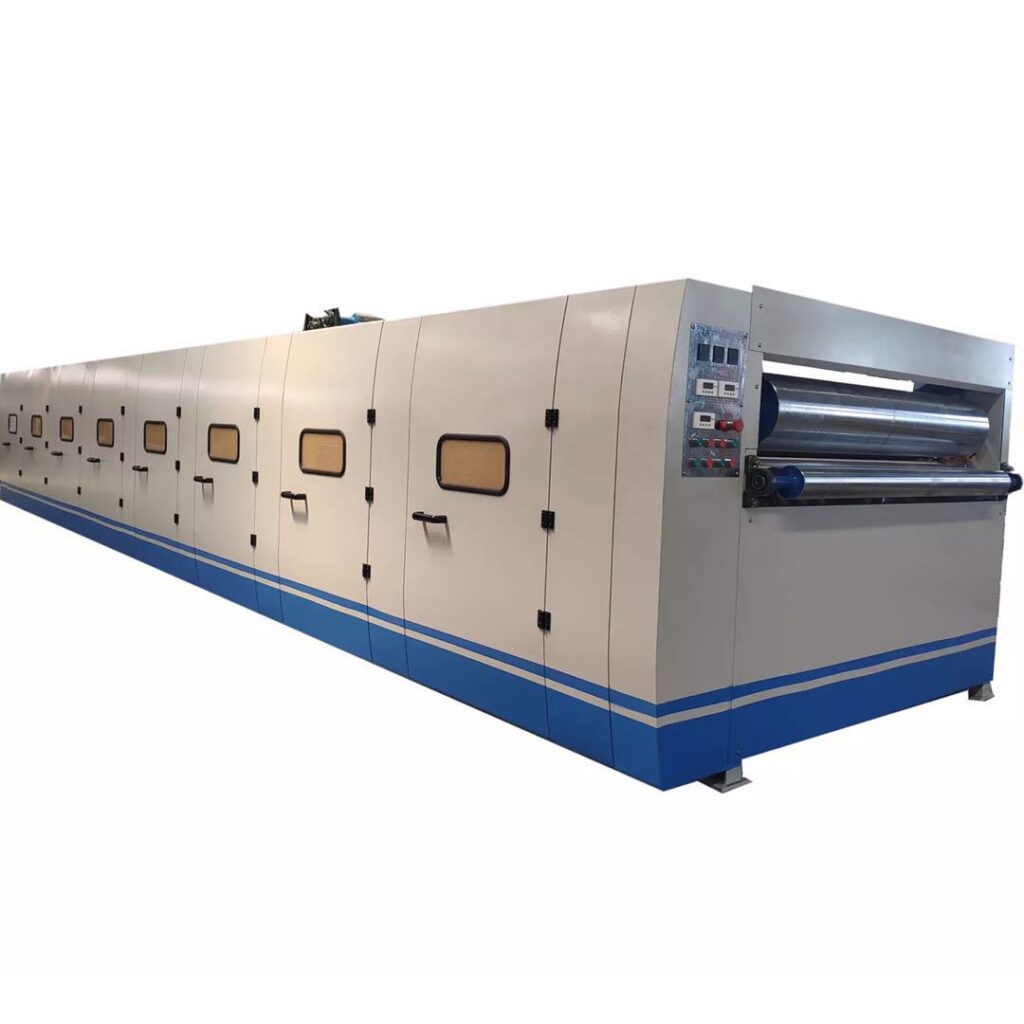

Technical Parameters

- Max Working Width: 1400-2800 mm (model-dependent)

- Board Thickness Range: 2-12 mm

- Heating Source: Steam, oil, or electric (optional)

- Temperature Control: Adjustable up to 200°C

- Max Production Speed: 120-300 m/min (depending on model)

- Pressing Belt Material: high quality high moisture absorbing cotton belt

- Power Supply: 380V, 50Hz, three-phase (customizable)

- Machine Dimensions: Length varies from 12-25 m (customizable based on production requirements)

Applications:

- Corrugated Board Production:

- Essential for bonding and curing linerboards to flutes, producing high-quality corrugated sheets.

- Packaging Manufacturing:

- Used in producing corrugated boxes for various industries, including logistics, retail, and industrial packaging.

- Food and Beverage Packaging:

- Ideal for creating corrugated boards used in packaging food products, beverages, and perishables.

- E-Commerce and Retail:

- Supports the production of durable boxes for shipping and storing consumer goods.

- Heavy-Duty Packaging:

- Produces robust boards for packaging machinery, automotive parts, and other heavy items.

- Custom Packaging Solutions:

- Facilitates the production of corrugated boards in various sizes, thicknesses, and specifications to meet diverse client needs.

- High-Speed Production Lines:

- Integrated into modern corrugated board production lines for continuous and high-volume manufacturing.