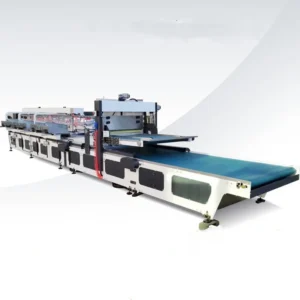

Characteristics of the semi automatic partition slotter machine:

1. Easy to operate, training is not necessary.

2. Working steadily and smoothly.

3. Speed range: 100-120 times/min.

4. It slots accurate and clear, no rough edge.

5. 4-5 time faster than other similar machines.

6. Elegant appearance and durable.

7. Frequency control speed (Option).

8. Vacuum absorb feeder (Option).

Technical parameter:

1. Motor: 1. 1KW

2. Maximum size of processed cardboard: 300mm-800mm

3. Minimum size of processed cardboard: 80mm-100mm

4. The minimum spacing of grooving: 40mm

5. Cutting width: 3mm- 5mm

6. Maximum depth of groove: 150mm

7. The maximum working speed is 100 sheets/min

8. Machine weight: 350kg

9. Machine shape length: length x width x height: 1500*1300*1000 mm

10. Thickness of processed cardboard: 2mm-5mm