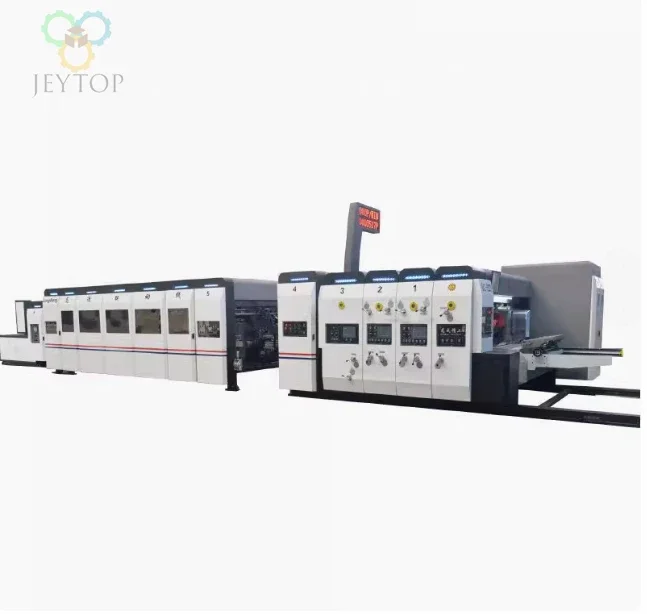

Characterics of flexo folder gluer:

1. Automated production: The flexo printing inline folder gluer machine can realize the automation of the entire production process through the intelligent control system, from raw material feeding, printing, die-cutting, gluing to packing, etc., without manual intervention, greatly improving production efficiency, reducing labor costs.

2. Good stability: The flexo folder gluer adopts advanced electronic control system and mechanical structure design, which has the characteristics of good stability and low failure rate, and can ensure the safety and quality of the production process.

3. Intelligent control: The flexo printer slotter die cutter inline folder gluer adopts an advanced intelligent control system, which can adjust production according to production needs and achieve optimization and adaptation of the production line.

Feeding unit

1.Electric control machine clutch attached to an alarm, warning road between the continuous ringing, to ensure the safety of workers.

2.Equipped with high effective brush roller and rows of brushes dust removal device.

3.Feeding unit is designed to be a perfect feeding system with functions of two vacuum suction transmission box, feeding roller, bush roller, and electrostatic dust.

4.Carton use automatic zero device, two test print can be adjusted to the correct position, reduce the waste of cardboard.

Printing unit

1.High quality cerimic anilox printing roller with doctor blade.

2.The anilox roller with quick-change structure, convenient maintenance and maintenance of the machine.

3.Full vacuum transfer type with belower,high precesion transfer vacuum box.

4.The printing nip Worm electric adjustment, digital display, the adjustment range of 0-12mm.

5.Automatic induction ink detection system, including warning lights and alarm bells.

Computer Slotting unit

1.The device self-locking function, the preload and quick adjustment mechanism ensures the long-term accuracy between the disc and the shaft, and reduces the cracking of the paper when pressing.

2.There are buttons, left and right synchronous intersections, electric axial movement, so that the upper and lower pressure line wheels, the upper and lower grooved knives are adjusted synchronously, and the electric adjusting box is highly functional.

3.A planetary gear type phase adjustment mechanism with digital display function is used for electric adjustment of the slotting

phase and the height of the slotting box.

Rotary Die Cutting unit

1.Die cutter phase adopt gear system, can be electric adjust 360 degree.

2.If stop feeding, the roller auto lifting,less damage.

3.Rubber plate roller can be lift right adjust 30mm, each blade cut in different position.

4.Up and down roller diameter different,but the line speed is same.can be control the die knives no stop working.make the plate

grinding uniform.

5.Line speed compensation device,when the rubber roller diameter change,the line speed will be compensation use this system.

Folder Gluer unit

1.The front section of the origami is conveyed by the precise stereotyped guide wheel system, and the rear section is transported by the adsorption belt. and does not appear to be deviated.

2.High-strength folding beam arm, precision traverse guiding system.

3.The origami beam adjusted left and right is controlled by computer , and can also be electrically adjusted.

4.The transmission and adsorption motor is controlled by electric motor.

5.The size of cardboard scissors is adjusted by belt differential.

Output paper counting unit

1.The number of count outputs can be set from 10 to 30 per pack.

2.The stacking method is a belt drive stack and a bottom plug stack.

3.The cardboard pushed by pneumatic cylinders.

Technical Parameter:

| Printing paper | A、B、C、A/B、B/C and A/B/C type corrugated paperboard(the Max. gap is 11 mm) | |||

| Max.paper size | 900x2000mm | 1200x2400mm | 1400x2600mm | |

| Width of machine inside | 2200mm | 2600mm | 2800mm | |

| Max.printing size | 900x1900mm | 1200x2300mm | 1400x2500mm | |

| Skip feeding paper | 1100x2000mm | 1400x2400mm | 1600x2600mm | |

| Min. paper size | Positive | 260x600mm | 350x680mm | 400x680mm |

| Negative | 260x680mm | 350x760mm | 400x760mm | |

| Printing plate thickness | 7.2mm | 7.2mm | 7.2mm | |

| Design speed | 150pcs/min | 150pcs/min | 150pcs/min | |

| Economic speed | 80-120pcs/min | 80-120pcs/min | 80-120pcs/min | |

| Tinted precision | 2/3/4 color±0.5/±0.5/±0.75mm | 2/3/4 color±0.5/±0.5/±0.75mm | 2/3/4 color±0.5/±0.5/±0.75mm | |

| Slotting presicion | ±1.5mm | ±1.5mm | ±1.5mm | |

| Max. slotting depth | 7x220mm | 7x300mm | 7x350mm | |

| Min. slot distance | positive | 140x140x140x140mm | 140x140x140x140mm | 140x140x140x140mm |

| Negative | 260x60x260x60mm | 300x60x260x60mm | 300x60x300x60mm | |

| Max. die-cutting size | 900x1950mm | 1200x2350mm | 1400x2550mm | |

| Printing roller diameter | Φ300mm | Φ405mm | Φ480mm |

Remarks:The size can be customized according to your requirement.