Characteristics of the Automatic Flexo Printer Slotter Die Cutter:

- The electrical appliances of the Fully Automatic Printing Slotting And Die Cutting Machine adopt internationally well-known brands “Siemens, Schneider”, and the quality is stable and reliable.

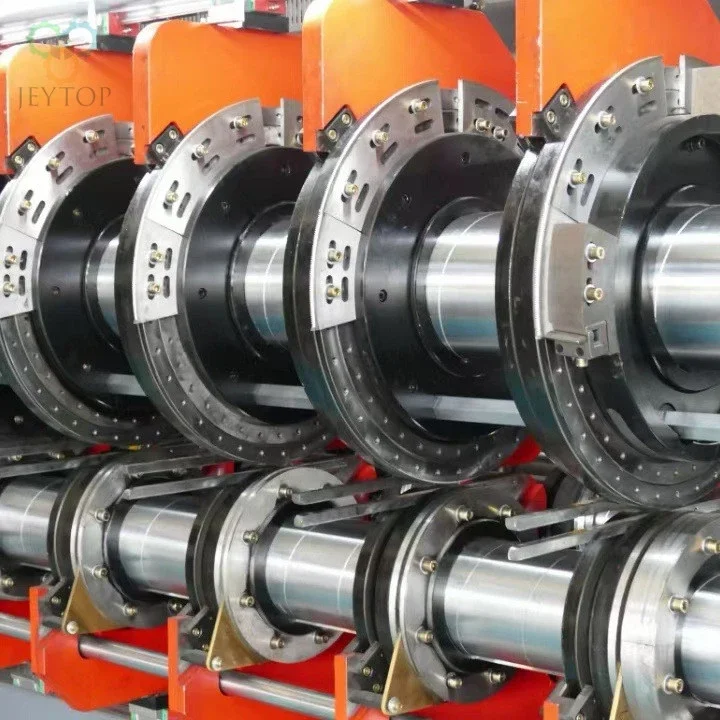

- The shafts and rollers of the whole machine are made of high-quality steel, processed by grinding, high-precision computer dynamic balance correction, and the surface is plated with hard chrome.

- The transmission gears of the whole machine are all made of 20CrMnTi alloy steel, carburized and quenched, and the hardness is HRC58~62; after the gear grinding, the accuracy of level 6 ensures the accuracy of color registration.

- The transmission parts (shaft and tooth connection) of the whole machine adopt keyless connection (expansion sleeve) to eliminate the connection gap, which is suitable for long-term high-speed operation with large torque.

- The transmission bearings and important transmission parts of the whole machine adopt “Havalo”, which is easy to maintain.

- The lubrication system of the whole machine adopts spray-type automatic lubrication, and is equipped with an automatic oil balance device.

- The working gap adjustment of the whole machine, self-locking worm gear, fast and convenient.

- The main engine fan adopts frequency conversion control, which makes the startup and operation more stable and saves electricity.

- The circular die-cutting part and the rotary slotting part are optional.

- Optional: ceramic anilox roller,doctor blade and stacker.

Technical Parameter of the automatic flexo printer slotter die cutter:

| Printing paper | A、B、C、A/B、B/C and A/B/C type corrugated paperboard(the Max. gap is 11mm) | ||

| Width of machine inside | 2200mm | 2600mm | 2800mm |

| Max. paper size | 900x2000mm | 1200x2400mm | 1400x2600mm |

| Max. printing size | 900x1900mm | 1200x2300mm | 1400x2500mm |

| Skip feeding paper | 1100x2000mm | 1400x2400mm | 1600x2600mm |

| Min. paper size PositiveNegative | 260x600mm260x680mm | 350x680mm350x760mm | 400x680mm400x760mm |

| Printing plate thickness | 7.2mm | 7.2mm | 7.2mm |

| Design speed | 150pcs/min | 150pcs/min | 150pcs/min |

| Economic speed | 80-120pcs/min | 80-120pcs/min | 80-120pcs/min |

| Tinted precision | 2/3/4 color±0.5/±0.5/±0.75mm | 2/3/4 color±0.5/±0.5/±0.75mm | 2/3/4 color±0.5/±0.5/±0.75mm |

| Slotting precision | ±1.5mm | ±1.5mm | ±1.5mm |

| Max. slotting depth | 7x220mm | 7x300mm | 7x350mm |

| Min. slot distance positiveNegative | 140x140x140x140mm260x60x260x60mm | 140x140x140x140m300x60x300x60mm | 140x140x140x140m300x60x300x60mm |

| Max. die-cutting size | 900x1950mm | 1200x2350mm | 1400x2550mm |

| Printing roller diameter | Φ300mm | Φ405mm | Φ480mm |

Hooshmand.R –

Love this printer! When we had a tiny setup question, their support got back in 10 mins. Machine runs smooth, no complaints here.