Product Highlights

- All-in-One Solution: Combines flexo printing, folding, and gluing in a single system for efficient production.

- High Precision: Provides high-quality printing and perfect folding/gluing for corrugated boxes.

- Flexible Design: Flexible design: suitable for various box sizes, applicable carton style is Regular Slotted Carton (RSC)

- High-Speed Operation: Ideal for large-volume box production with quick changeover times.

- Energy Efficient: Designed for low power consumption without compromising speed or quality.

- User-Friendly: Easy-to-operate control systems for seamless production management.

Technical Parameters

General Specifications:

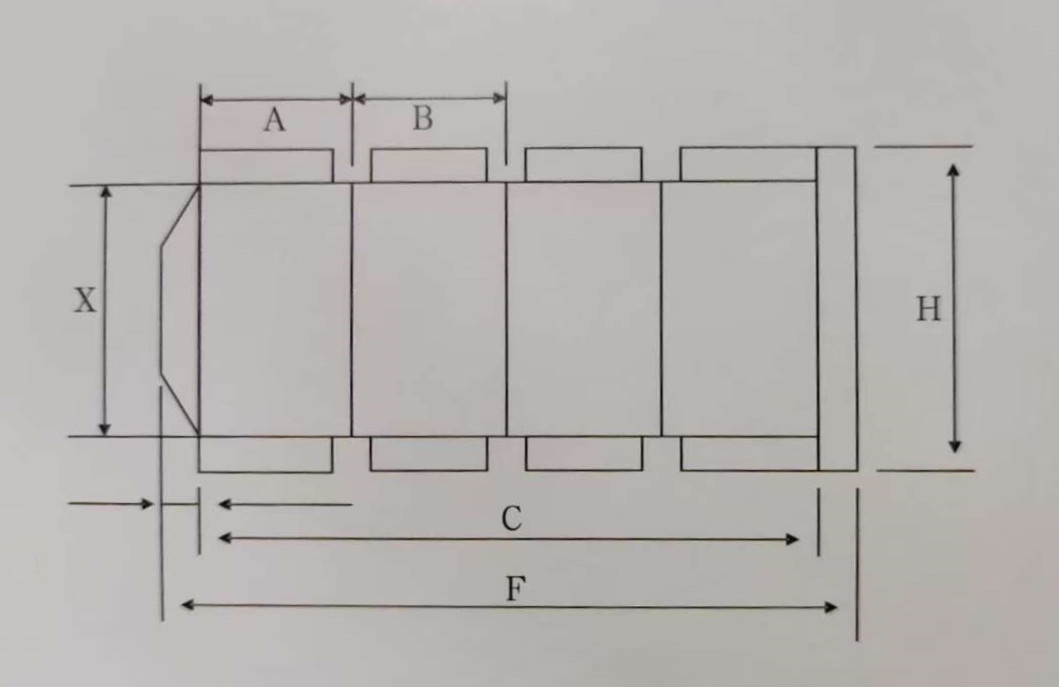

| Specification | 920 | 1224 | 1424 | 1628 |

|---|---|---|---|---|

| Machine Size (mm) | 900×2200 | 1250×2600 | 1400×2600 | 1600×2800 |

| A Maximum (mm) | 750 | 850 | 850 | 850 |

| A Minimum (mm) | 130 | 135 | 135 | 135 |

| B Maximum (mm) | 750 | 850 | 850 | 850 |

| B Minimum (mm) | 130 | 135 | 135 | 135 |

| C Maximum (mm) | 2200 | 2600 | 2600 | 2720 |

| C Minimum (mm) | 600 | 620 | 620 | 620 |

| F Board Length Maximum (mm) | 2200 | 2600 | 2600 | 2800 |

| Z Glue Width Maximum (mm) | 2200 | 2600 | 2600 | 2800 |

| X Box Height Minimum (mm) | 40 | 40 | 40 | 40 |

| H Single Sheet Board Width Max (mm) | 920 | 1200 | 1400 | 1600 |

| H Single Sheet Board Width Min (mm) | 250 | 350 | 400 | 450 |

| Printing Area Maximum (mm) | 900×2000 | 1200×2400 | 1400×2400 | 1600×2800 |

| Die Cutting Area Maximum (mm) | 900×2100 | 1100×2500 | 1400×2600 | 1600×2800 |

| Unfolded Board Maximum (mm) | 1550 | 1650 | 1650 | 1650 |

| Machine Speed (Sheets/Min) | 300 | 250 | 200 | 180 |

| Power (Approx.) (kw) | 45 | 50 | 50 | 50 |

Features & Benefits

- Flexo Printing: Up to 5-color printing for high-quality graphics and branding.

- Slotting and Die Cutting: Adjustable slotting knives and rotary die cutting provide flexibility for producing a variety of box styles.

- Folder Gluer: The inline gluing unit ensures precise folding and gluing, resulting in strong, neatly finished boxes.

- High Efficiency: The FFG combines several steps into one machine, reducing production time and increasing throughput.

- Automatic Stacking: Automatically stacks finished boxes, reducing manual labor and increasing output efficiency.

Applications

- Corrugated Box Manufacturing: Ideal for producing corrugated packaging in various industries such as food & beverage, electronics, and consumer goods.

- Custom Packaging: Suitable for producing custom-sized boxes with printing and special features.

- Packaging Line Integration: Easily integrates with other machines in the production line for a seamless workflow.

Why Choose Our FFG Machine?

- Comprehensive Functionality: Combines flexo printing, slotting, die cutting, and gluing, saving space and improving efficiency.

- High Productivity: Designed for high-speed production without compromising on quality.

- Easy Maintenance: Equipped with user-friendly controls and maintenance features for minimal downtime.

- Energy Saving: Optimized design reduces electricity and steam consumption, lowering operating costs.

- Flexible Production: Supports a wide range of box sizes, styles, and designs for versatile packaging solutions.